Drawing compound molding die for shell with tooth form on side wall

A compound forming and tooth shape technology, applied in the field of machinery, can solve problems such as limited popularization, complex mold structure, and difficult-to-form parts, and achieve the effects of reducing production costs, simplifying mold structure, and reducing forming force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be described in further detail below in conjunction with the examples. This embodiment is based on the premise of the technical solution of the present invention, providing detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the following implementation example.

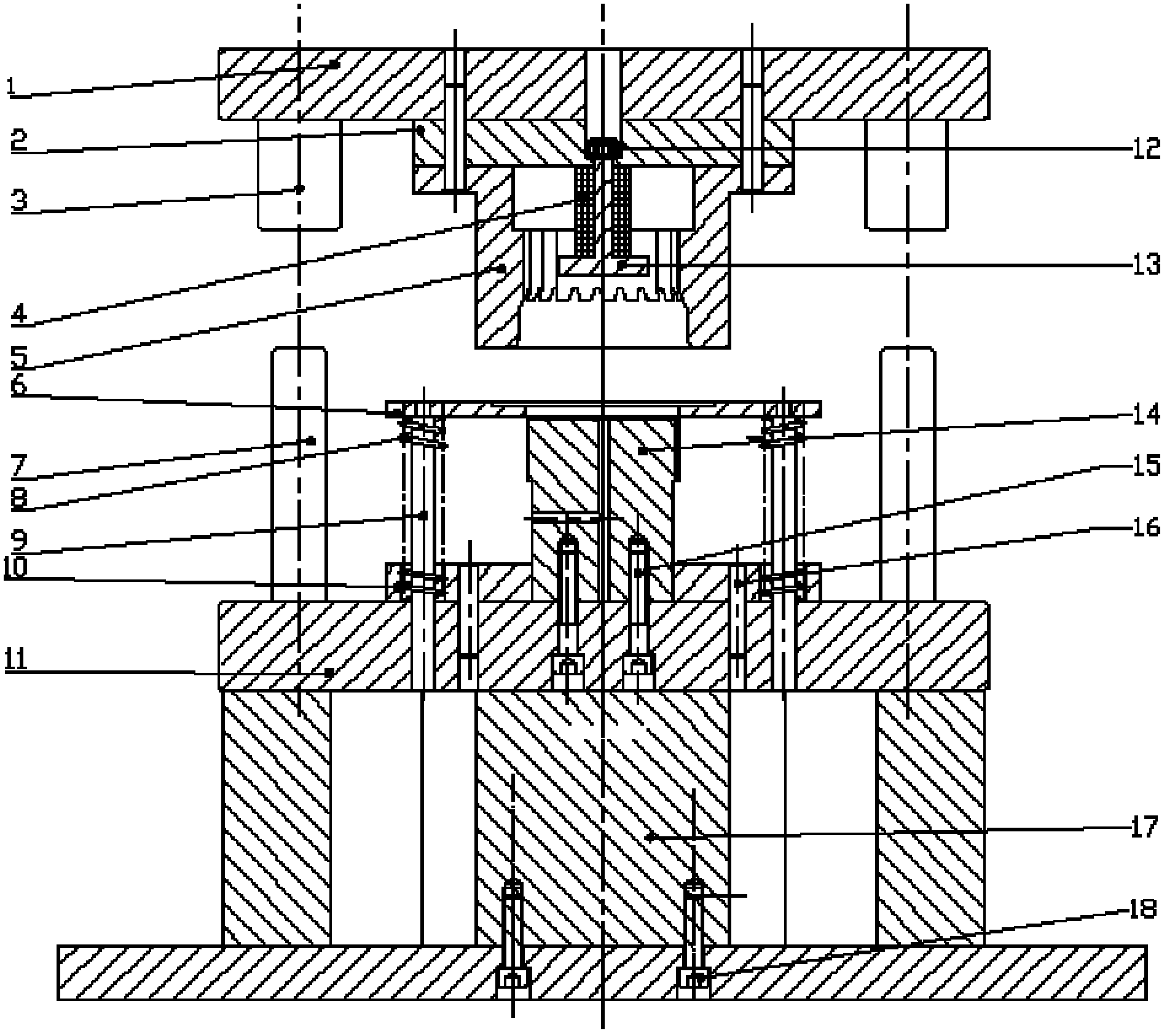

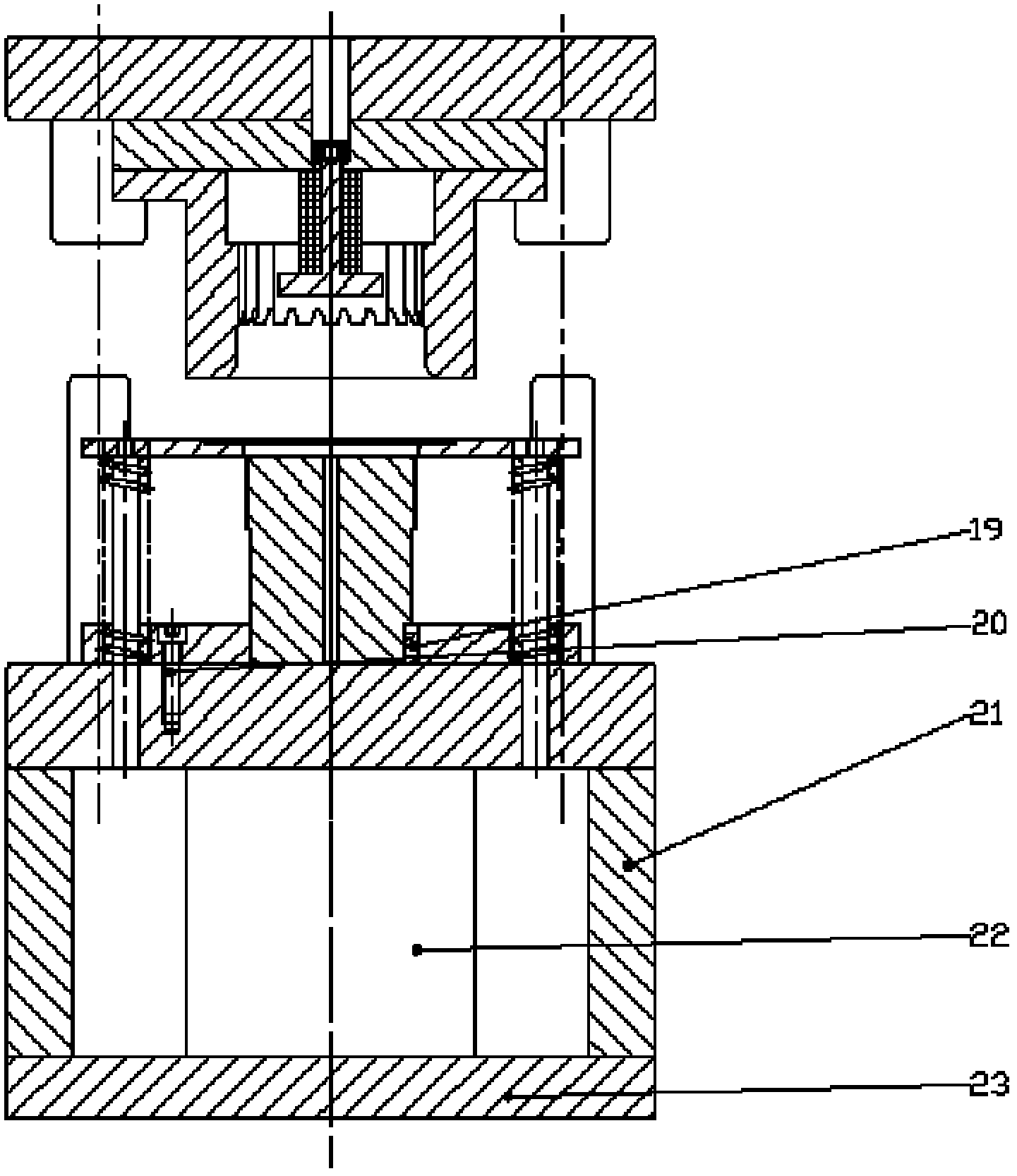

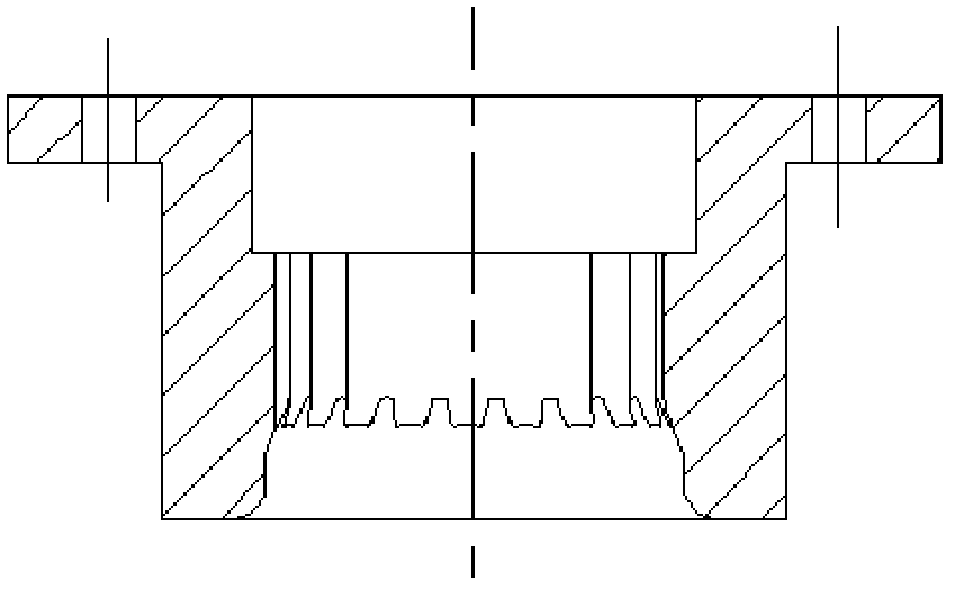

[0025] Please also see figure 1 and figure 2 The structure schematic diagram of the present invention shows that the drawing compound forming mold for the toothed shell on the side wall includes an upper mold part and a lower mold part capable of relative movement.

[0026] The upper mold part includes an upper mold base 1, a backing plate 2, a top piece device and a die 5. A guide sleeve 3 is arranged on the upper mold base 1 . The die 5 is fixed on the upper die base 1 through the backing plate 2 by pins, and the backing plate 2 is sandwiched between the upper die base 1 and the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com