Premix compound for producing snowflake beef and preparation method thereof

A premix, snowflake beef cattle technology, applied in the application, animal feed, animal feed and other directions, can solve the problems of less effective ingredients, high coefficient of variation, poor stability, etc., and achieve the effect of good stability and high effective ingredients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

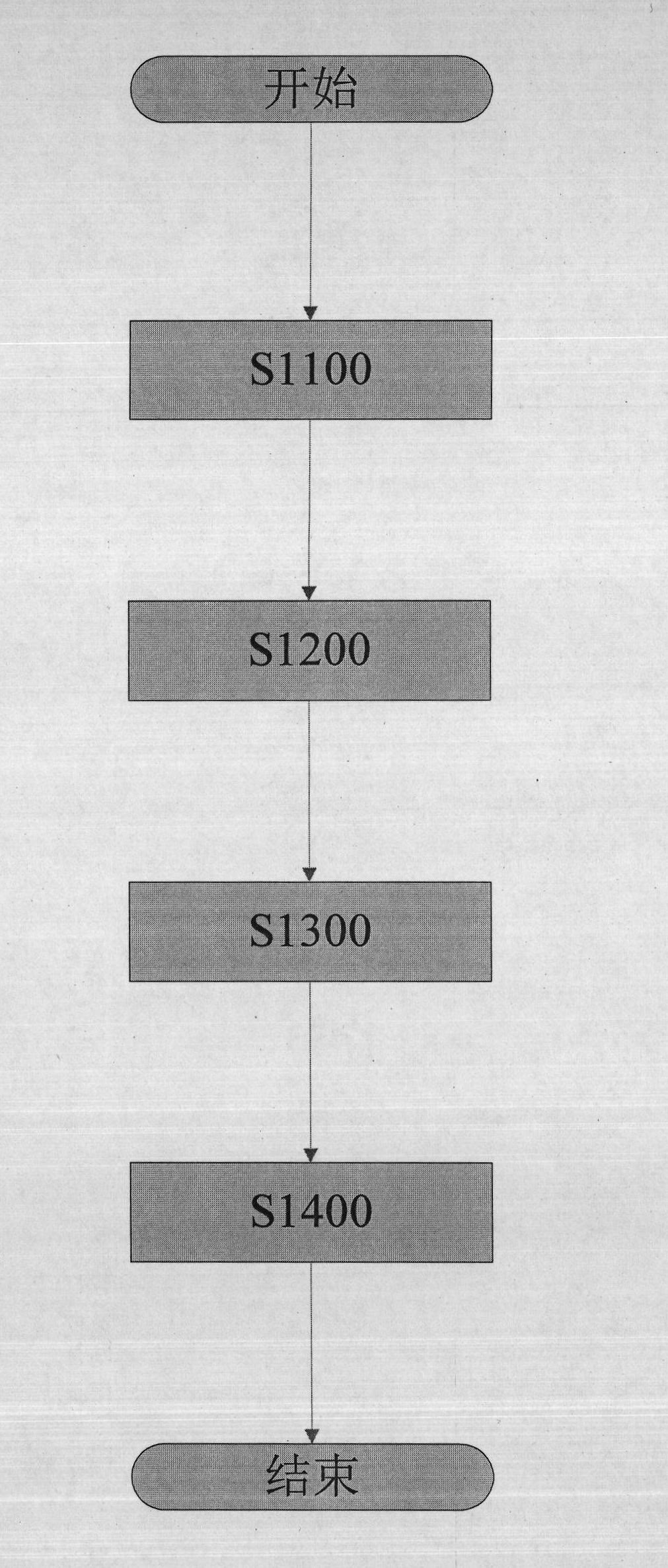

[0024] This embodiment is a premix designed for the pre-fattening stage of snowflake beef cattle and a preparation method thereof. In step S1100 of this embodiment, the applicant optimized the composition ratio through a large number of experiments, and obtained the following optimal composition ratio scheme suitable for the fattening stage of snowflake beef cattle:

[0025]

[0026]

[0027] (Note: the units of vitamins in each embodiment are 500,000 IU / g)

[0028] Perform the operation of step S1200 on the component formula obtained by the above optimization, that is, to grind the above-mentioned components separately;

[0029] Afterwards, the operation of step S1300 is started, and the ground components are sieved separately with standard sieve holes of 80 to 100 meshes;

[0030] Finally, the operation of step S1400 is performed, and the sieved components are sequentially added to the container for preparing the premix in the following order: feed grade calcium hydro...

Embodiment 2

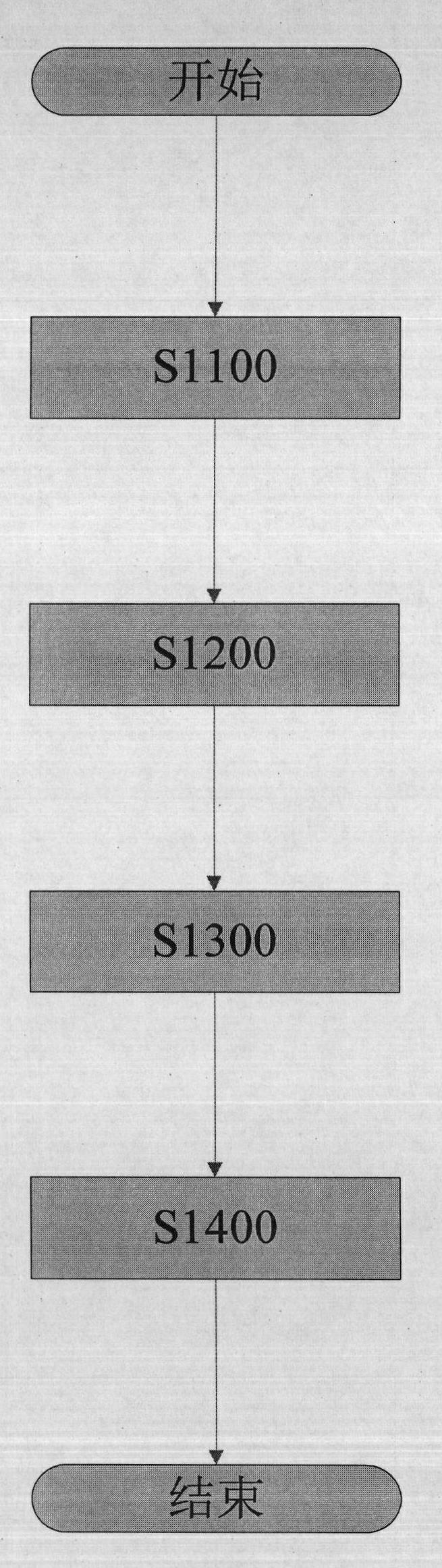

[0032] This embodiment is the preparation method of the premix designed for the mid-fattening period of snowflake beef cattle. In step S1100 of this embodiment, the applicant optimized the composition ratio through a large number of experiments, and obtained the following optimum composition ratio scheme suitable for the mid-fattening period of snowflake beef cattle:

[0033]

[0034]

[0035] Perform the operation in step S1200 with the above optimized component formula, that is, to grind the above-mentioned components separately;

[0036] Afterwards, the operation of step S1300 is carried out, and the ground components are sieved separately with standard sieve holes of 80 to 100 meshes;

[0037] Finally, the operation of step S1400 is carried out, and the sieved components are sequentially added to the container for preparing the premix in the following order: stone powder, feed grade calcium hydrogen phosphate, zinc sulfate, manganese sulfate, magnesium sulfate, coppe...

Embodiment 3

[0039] This embodiment is the preparation method of the premix designed for the late fattening of snowflake beef cattle. In step S1100 of this embodiment, through a large number of experiments, the applicant optimized and obtained the following optimal component ratio scheme suitable for the mid-fattening period of snowflake beef cattle:

[0040]

[0041]

[0042] Perform the operation in step S1200 with the above optimized component formula, that is, to grind the above-mentioned raw materials respectively;

[0043]Afterwards, the operation of step S1300 is carried out, and the ground components are sieved respectively with standard sieve holes of 80 to 100 meshes;

[0044] Finally, the operation of step S1400 is carried out, and the screened components are sequentially added to the container for preparing the premix in the following order: stone powder, feed grade calcium hydrogen phosphate, zinc sulfate, manganese sulfate, magnesium sulfate, copper sulfate, chlorine A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com