Method for controlling dividing-wall distillation column

A technology of dividing wall rectification tower and control method, which is applied in the control field of dividing wall rectification tower to separate multi-component mixtures, and can solve the problem that the operation of the dividing wall rectification tower cannot be ensured, stable control cannot be realized, and there is no other variable group selection and improved control regulation evaluation issues such as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described; But those skilled in the art should understand that, this embodiment does not limit the present invention method to use other control models except PID, and changes in other ranges occur in feed flow Or the content of other feed components changes, or the application of separating other multi-component mixtures.

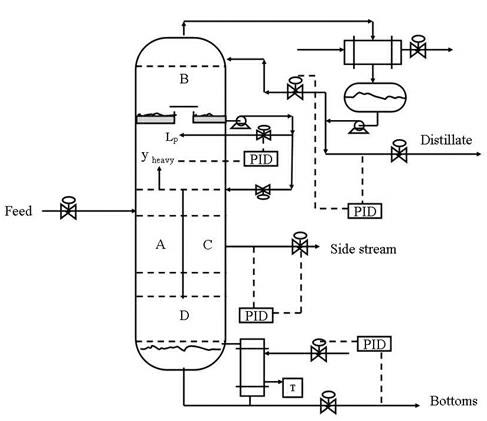

[0045] Such as image 3 The shown divide-wall rectification tower with 4 PID control loops is used to separate the mixture based on benzene / toluene / xylene, taking 10% reduction of toluene in the feed as an example, the specific control method described in the present invention Applications.

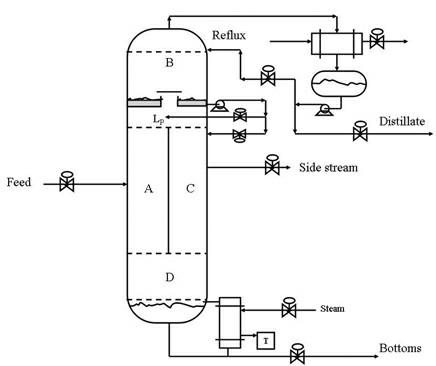

[0046] Described dividing wall rectification tower, A is the pre-fractionation section, has 46 trays in total, B is the rectification section, has 17 trays in total, C is the side line discharge section, has 46 trays in total, and D is the stripping section , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com