Semi-automatic steel backing gluing machine

A glue applicator, semi-automatic technology, applied in the direction of coating, liquid coating device on the surface, surface pretreatment, etc., can solve the problems of harmful gas, glue overflow around the steel back, discharge, etc., to reduce waste and save production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

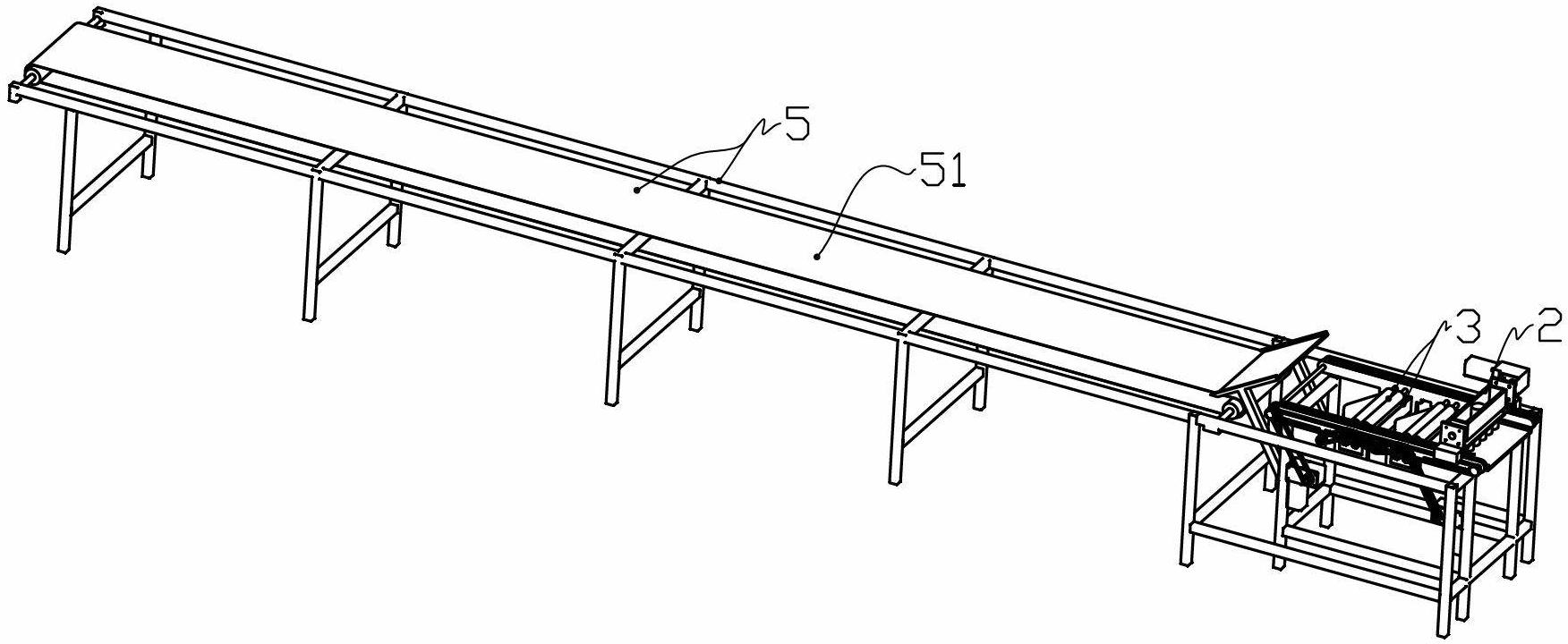

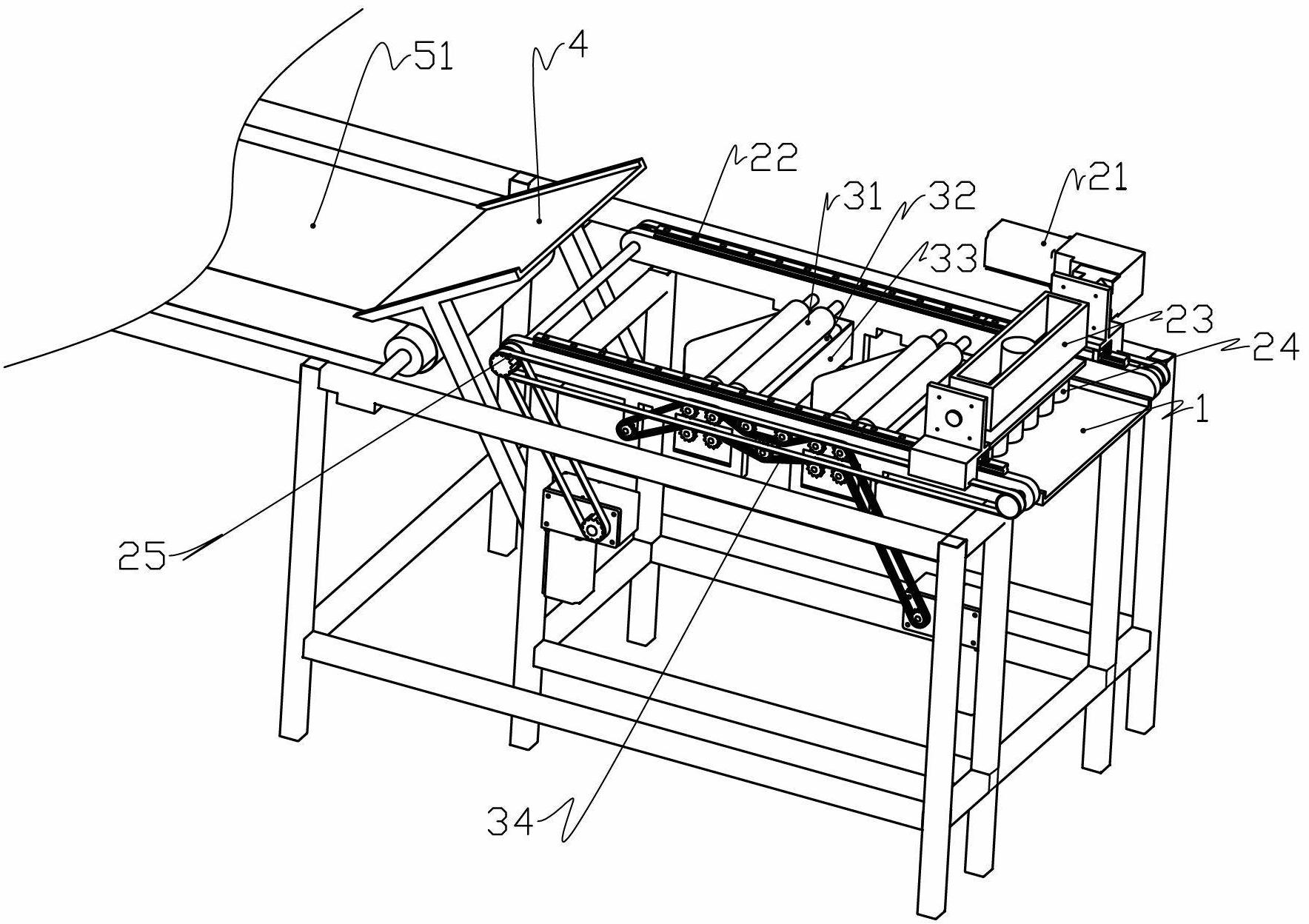

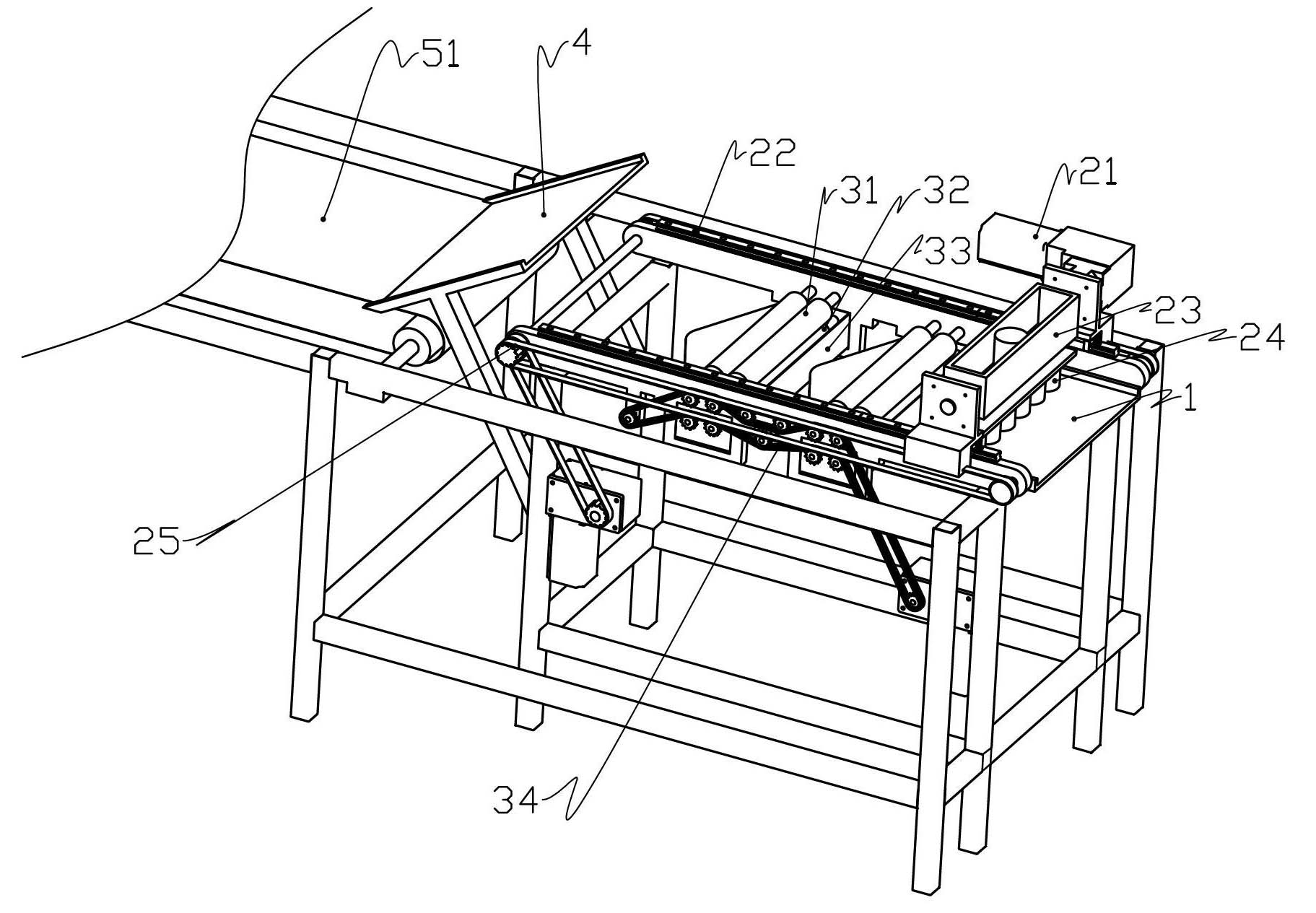

[0021] Such as figure 1 , figure 2 As shown,

[0022] This semi-automatic steel back gluing machine is mainly used for steel back gluing and consists of two parts: the glue area and the air-drying area. The gluing area is used to achieve uniform gluing and has a series of functions of clamping, conveying, and gluing. The air-drying area mainly realizes the air drying of the glued steel back through circulating air to achieve the purpose of air drying.

[0023] The gluing area is the area where the glue is applied. From front to back, the gluing area is the steel back placement table 1, the electromagnetic manipulator device 2, the rubber roller device 3, and the guide plate 4 in sequence. The steel-backed mounting platform 1 is a steel-backed mounting platform, which is directly fixed on the frame and is located at the starting end. The steel back is placed on the steel back placement table 1, and then the electromagnetic manipulator device moves to the steel back placement tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com