Novel non-refrigeration infrared sensor wafer-level packaging method compatible with CMOS (Complementary Metal Oxide Semiconductor)-MEMS (Micro-Electro-Mechanical System)

A wafer-level packaging and uncooled infrared technology, which is applied in the manufacture of microstructure devices, decorative arts, microstructure devices, etc., can solve the problems of increasing the complexity of processing technology, materials that cannot be used in factories, and environmental protection. Mass production, easy mass production, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in conjunction with the accompanying drawings.

[0019] The purpose and technical solutions of the present invention will be described in detail below in conjunction with specific examples. The etching process, the film material growth process, and the dry etching process are all existing processes.

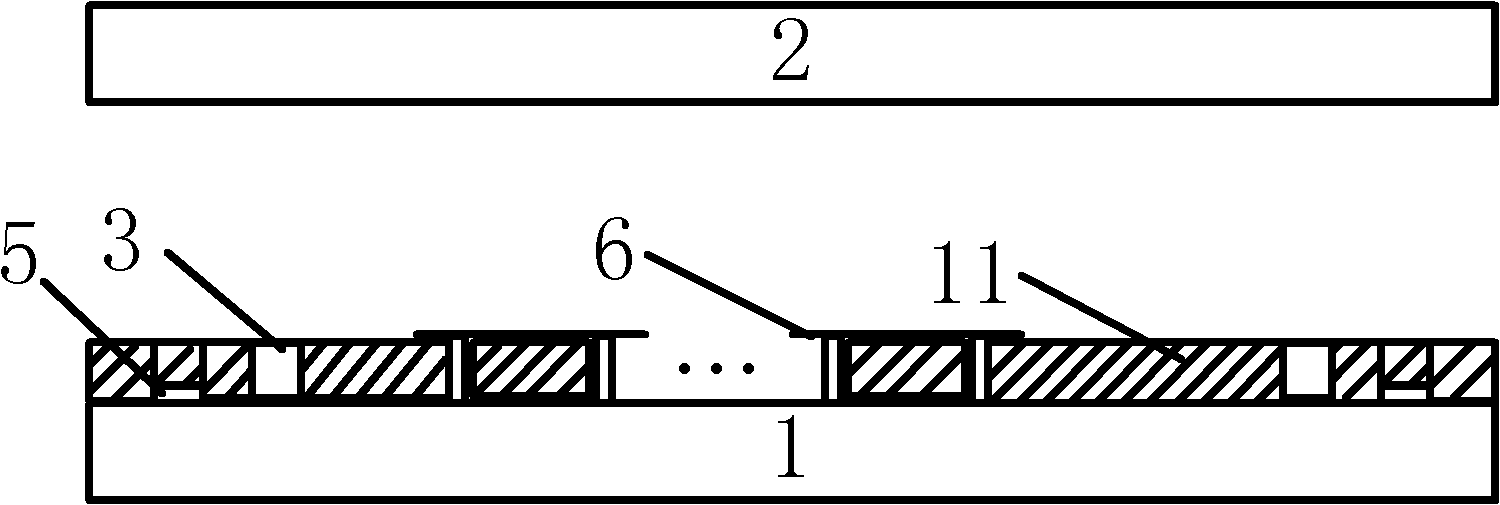

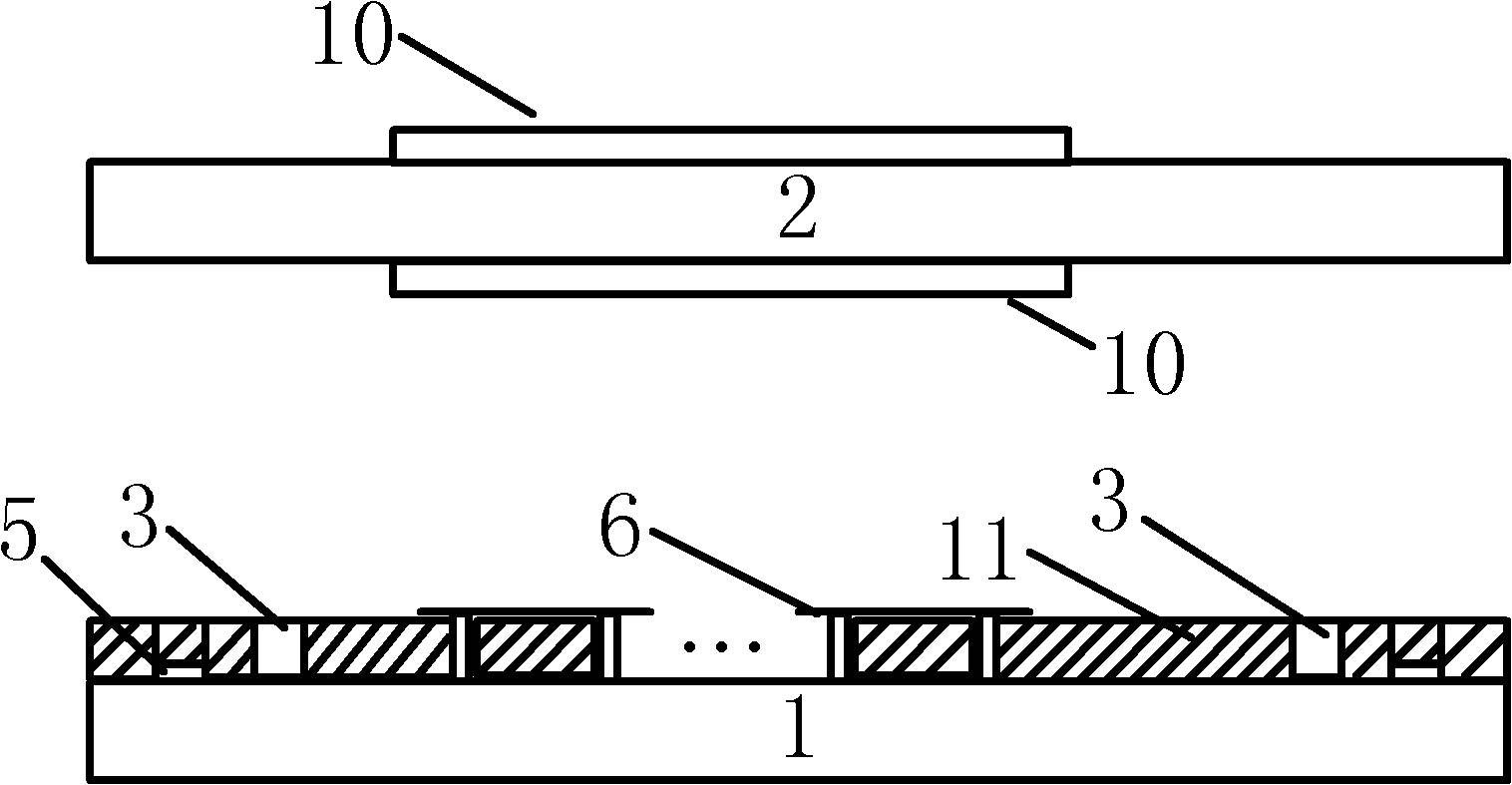

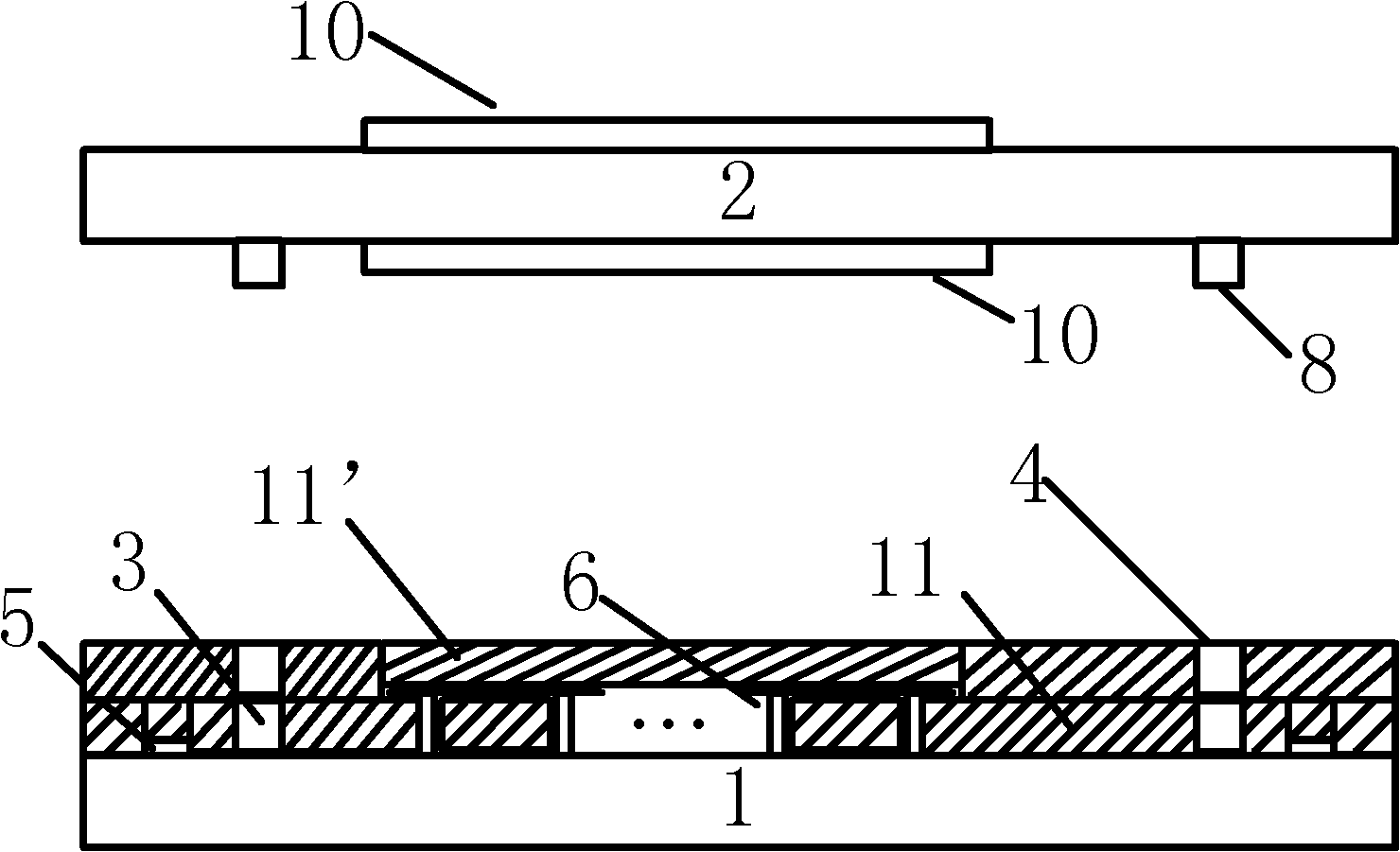

[0020] Such as figure 1 , figure 2 As shown, the device wafer 1 has a readout circuit 5, a detector sensitive element 6, a first sacrificial layer 11 and a first structural layer 3, the thickness of the first sacrificial layer 11 is 2-2.5um, and the first structural layer 3 and the height of the detector sensitive element 6 are consistent with the height of the first sacrificial layer 11, the first sacrificial layer 11 is not released, and the material 3 of the first structural layer is silicon nitride or silicon oxide; image 3 As shown, the second sacrificial layer 11' is prepared on the device wafer 1 with a thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com