Method and device for removing light components in trioxymethylene

A technology for trioxymethylene and light components, which is applied in fractionation, organic chemistry and other directions, can solve the problems of high energy consumption of towers, small operation flexibility for removing light components, easy decomposition of trioxymethylene, etc. Reduces, avoids massive decomposition, and improves product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

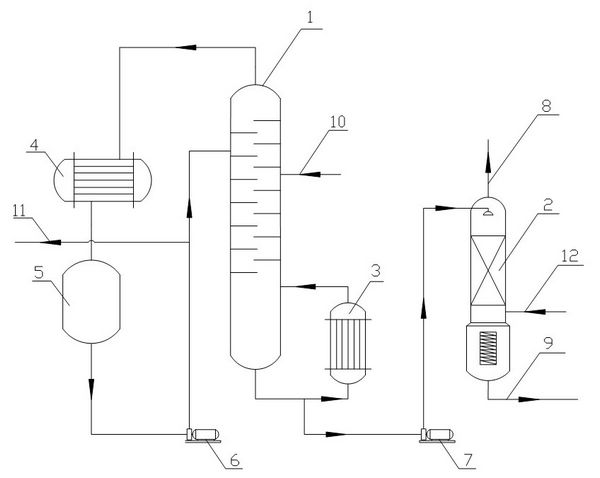

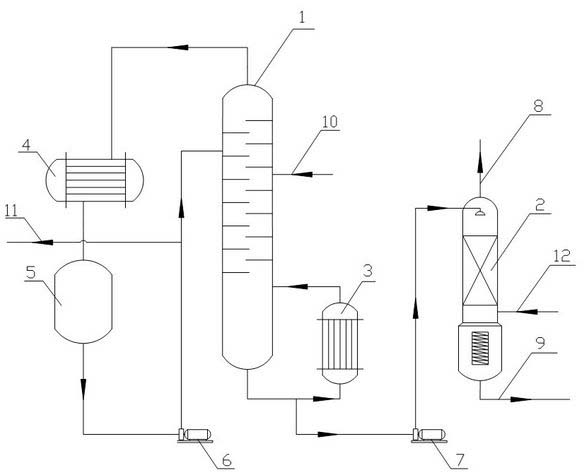

Image

Examples

Embodiment 1

[0019] (1) Send the extracted mixture of paraformaldehyde, benzene, a small amount of water and organic matter into the light removal tower, and carry out the removal under the conditions of tower bottom temperature 120°C, tower top temperature 79°C, reflux ratio 2, and pressure 2Kpa. Light, the top gas of the light removal tower returns to the extraction process after being condensed and cooled.

[0020] (2) The mixture of paraformaldehyde and trace amounts of water, methanol, formaldehyde, formic acid, etc. at the bottom of the tower after light removal is sent to the stripping tower. The stripping tower uses nitrogen as the stripping medium. The stripping is carried out at a temperature of 115°C and a pressure of 1Kpa.

[0021] After detection and analysis, the content of paraformaldehyde in the bottom of the stripping tower is 99.99%, the content of methanol is 27ppm, the content of formaldehyde is 28ppm, the content of formic acid is 14ppm, and the content of water is 22p...

Embodiment 2

[0023] (1) Send the extracted mixture of paraformaldehyde, benzene, a small amount of water and organic matter into the light removal tower, and carry out the removal under the conditions of tower bottom temperature 122°C, tower top temperature 79°C, reflux ratio 3, and pressure 5Kpa. Light, the top gas of the light removal tower returns to the extraction process after being condensed and cooled.

[0024] (2) The mixture of paraformaldehyde and trace amounts of water, methanol, formaldehyde, formic acid, etc. at the bottom of the tower after light removal is sent to the stripping tower. The stripping tower uses nitrogen as the stripping medium. The stripping is carried out under the conditions of temperature 116°C and pressure 5Kpa.

[0025] After detection and analysis, the content of paraformaldehyde in the bottom of the stripping tower is 99.97%, the content of methanol is 40ppm, the content of formaldehyde is 35ppm, the content of formic acid is 25ppm, and the content of w...

Embodiment 3

[0027] (1) Send the extracted mixture of paraformaldehyde, benzene, a small amount of water and organic matter into the light removal tower, and carry out the process under the conditions of tower bottom temperature 118°C, tower top temperature 78°C, reflux ratio 1, and pressure 0.1Kpa. Light removal, the top gas of the light removal tower returns to the extraction process after being condensed and cooled.

[0028] (2) The mixture of paraformaldehyde and trace amounts of water, methanol, formaldehyde, formic acid, etc. at the bottom of the tower after light removal is sent to the stripping tower. The stripping tower uses nitrogen as the stripping medium. The stripping is carried out under the conditions of temperature 114°C and pressure 0.1Kpa.

[0029] After detection and analysis, the content of paraformaldehyde in the bottom of the stripping tower is 99.95%, the content of methanol is 115ppm, the content of formaldehyde is 128ppm, the content of formic acid is 56ppm, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com