Single-cylinder pressure device applicable to cotton lap pressure of strip and lap combination machine

A pressurizing device and a single cylinder technology, which is applied in the direction of winding mechanism, textile and paper making, fiber processing, etc., can solve the problems of impact, noise power, loss and pressurization law, etc., and achieve simple structure of the device, economical and practical, and reduce energy The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

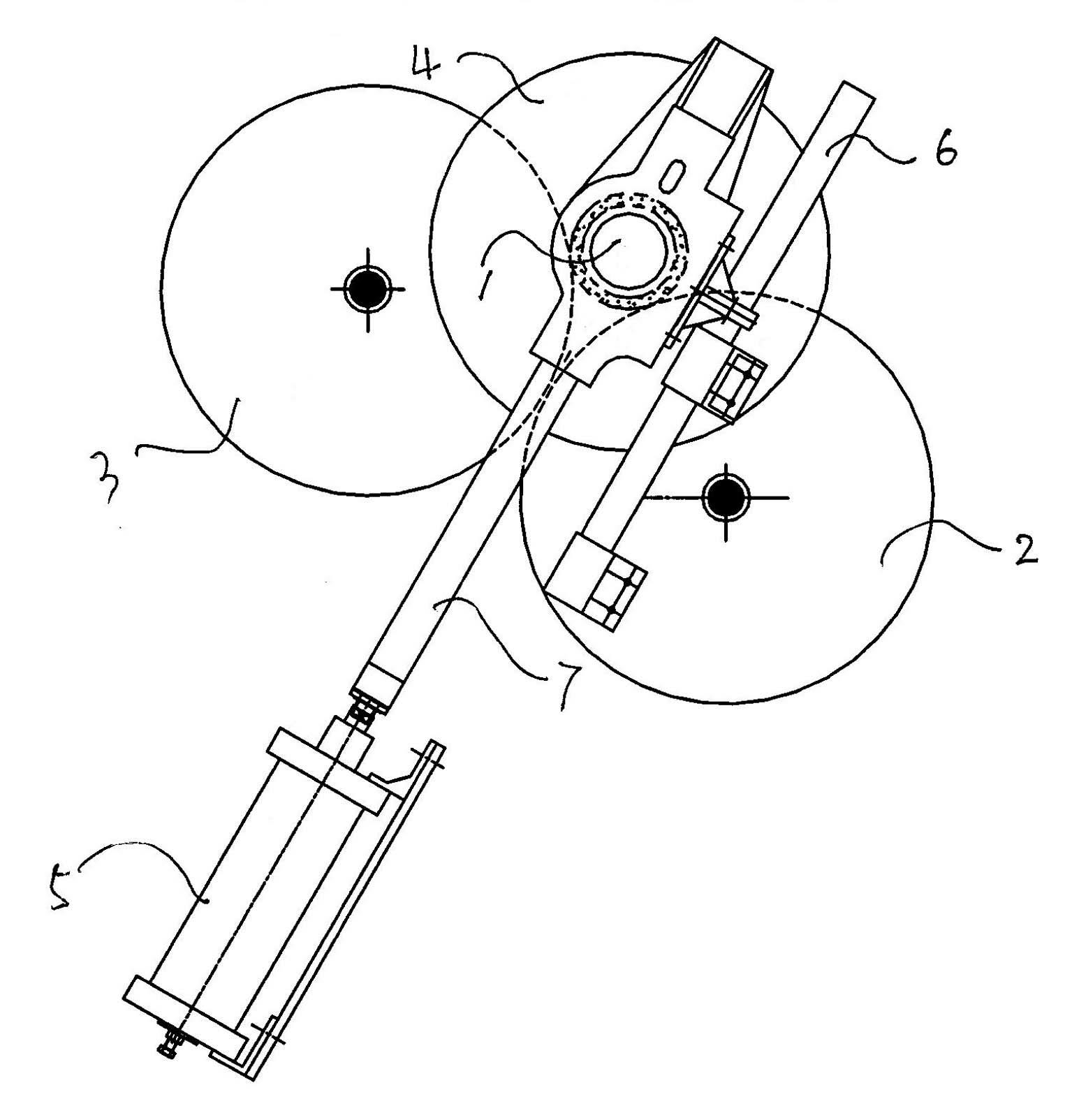

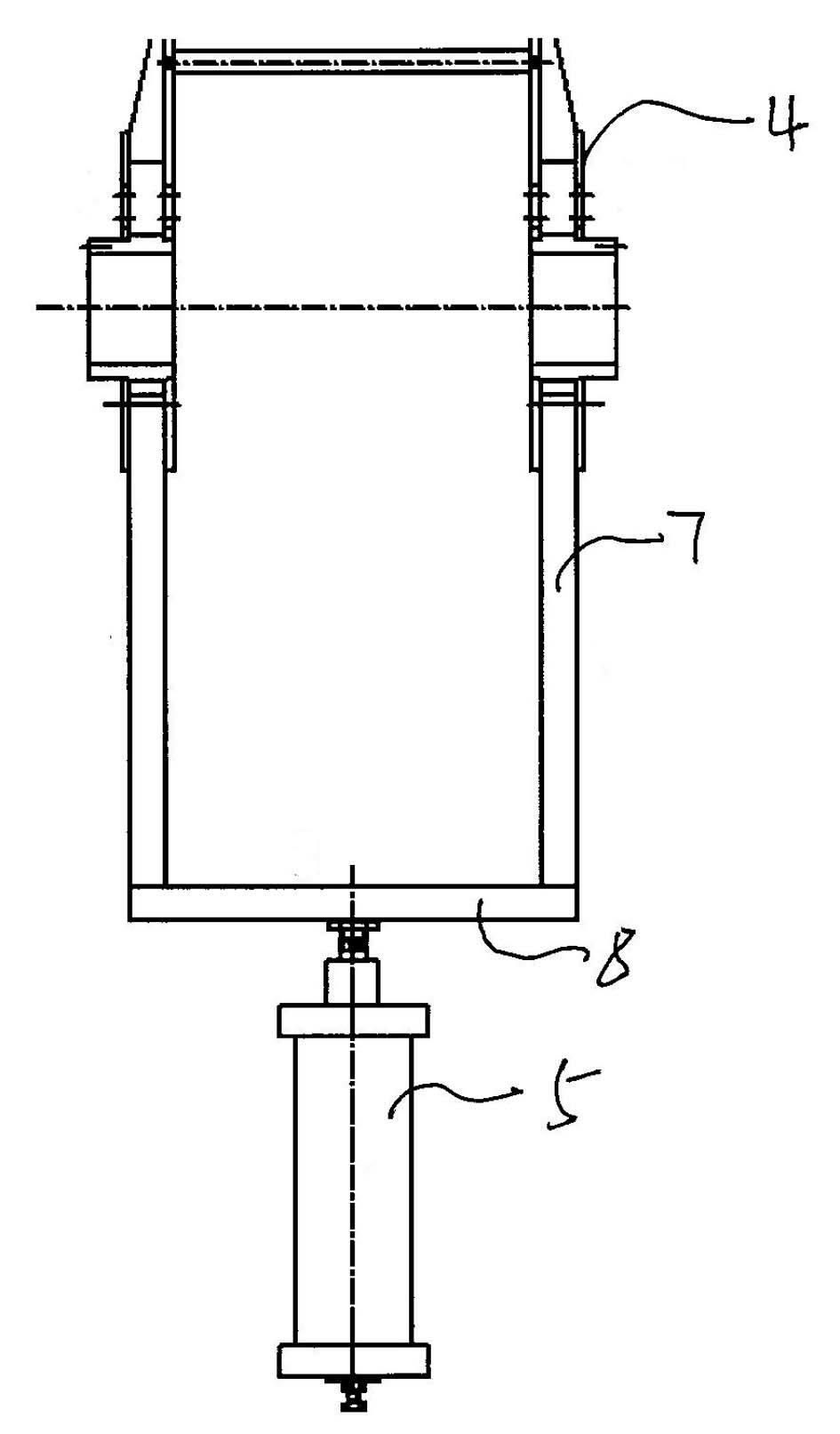

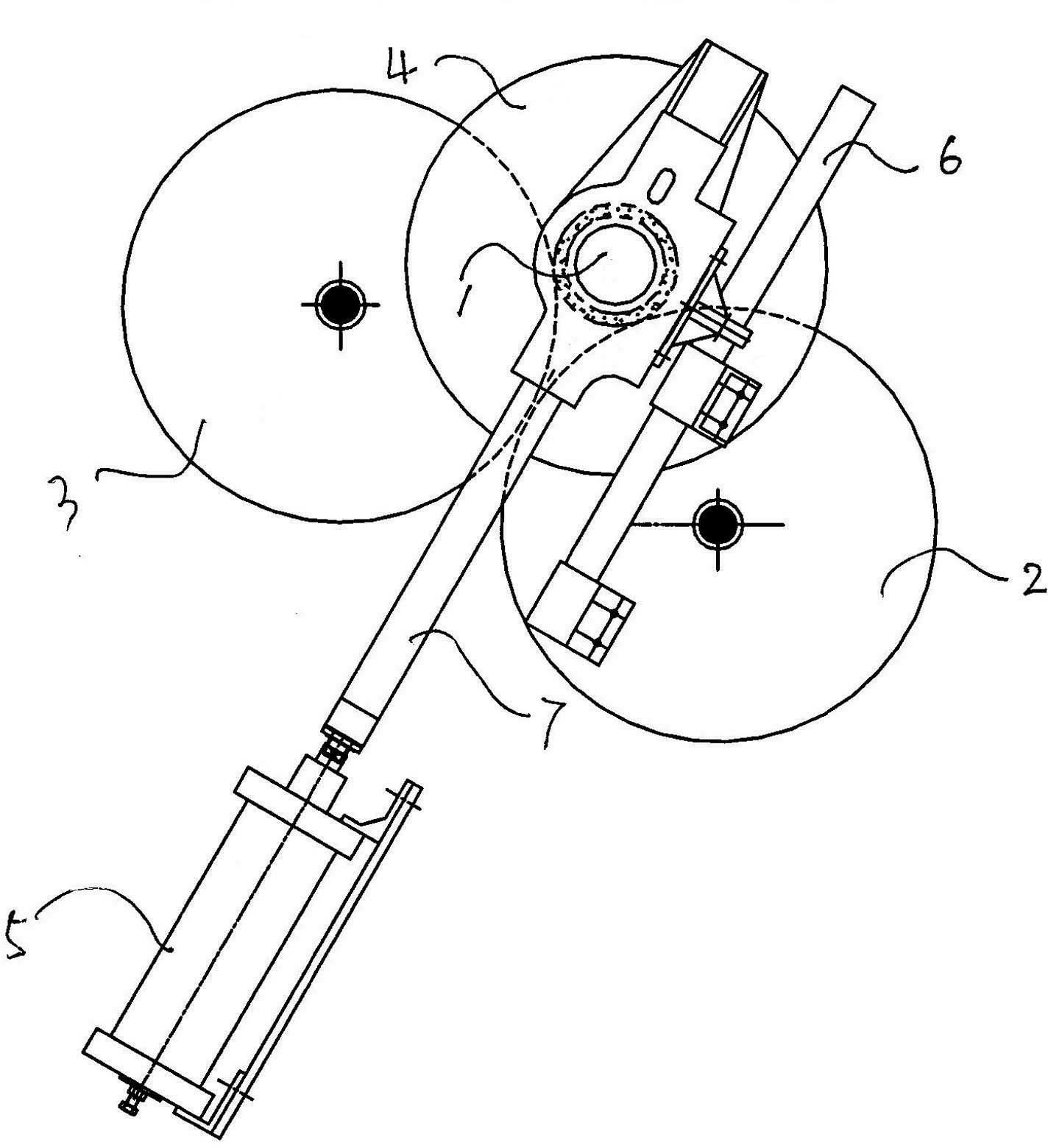

[0014] like figure 1 , figure 2 As shown, a single-cylinder pressurizing device of the present invention suitable for ladle pressurization of a strip-winding combined machine includes left and right lifting arms 7 that move up and down along the left and right guide rails 6, and left and right clips that are embedded in the upper parts of the left and right lifting arms 7 at both ends. The bobbin 1 that holds the cotton layer in the groove of the disc 4 is rigidly connected to the horizontal connecting rod 8 at the lower end of the left and right lifting arms 7; Combined with the piston rod of the volume pressurized cylinder 5.

[0015] Concrete pressurization method of the present invention is as follows:

[0016] As the winding progresses, the cotton roll becomes larger and larger, the position of the cotton roll tube 1 rises, the left and right clamping discs 4 rise with the bobbin tube, and the left and right lifting arms 7 also rise along the guide rails. The cross b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com