Hybrid vehicle thermal management using a bypass path in a catalytic converter unit

A hybrid vehicle and catalytic converter technology is applied in the arrangement of multiple different prime movers of hybrid vehicles, motor vehicles, and general power plants to achieve the effect of maintaining thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

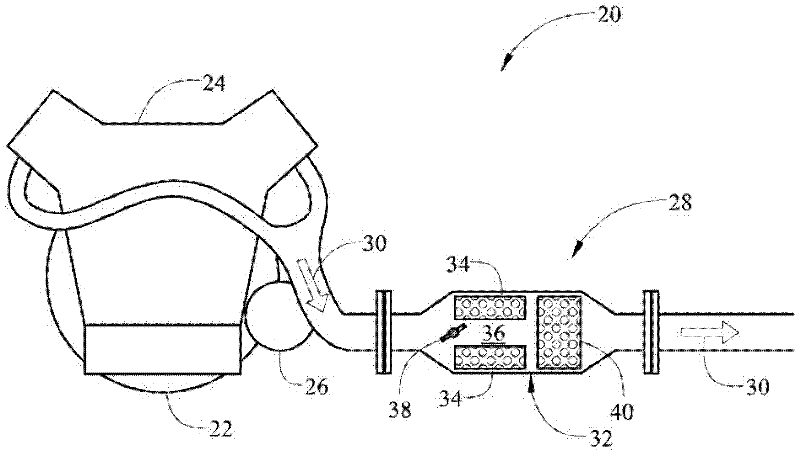

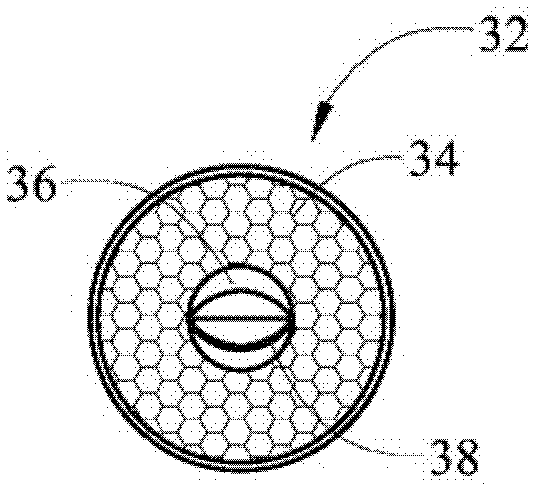

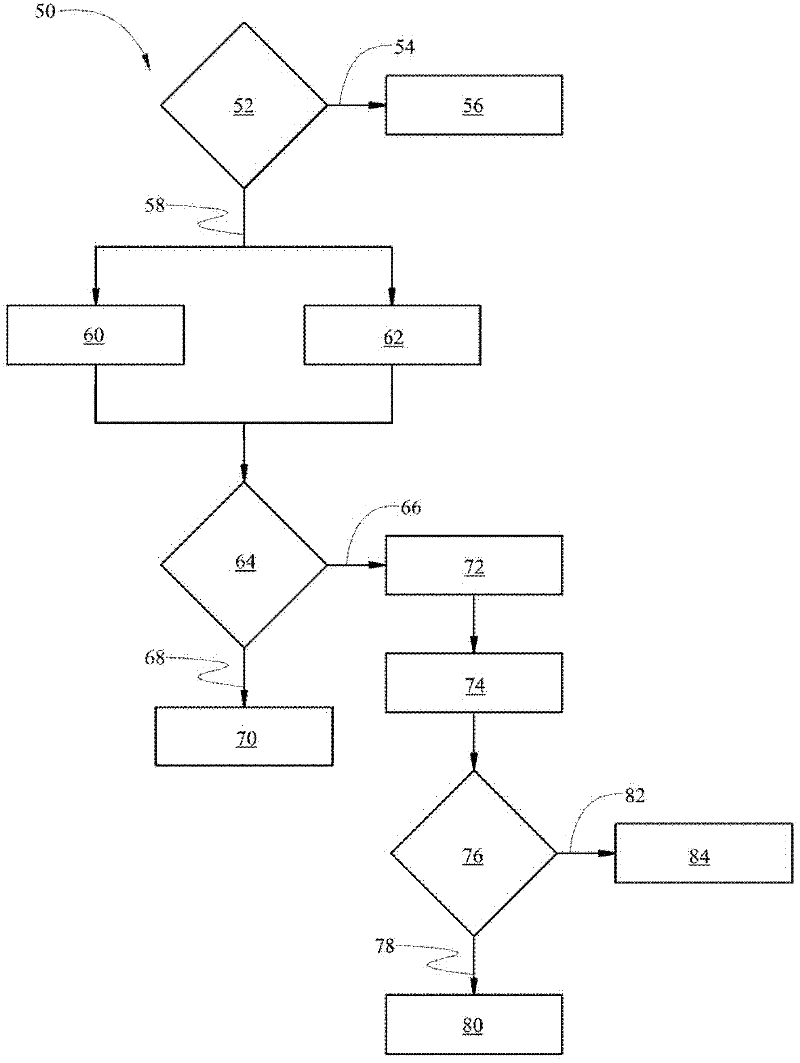

[0012] With reference to the drawings, where the same reference numerals in multiple views indicate the same parts, the hybrid vehicle figure 1 Is shown generally at 20. reference figure 1 , The hybrid vehicle 20 includes a transmission 22. The transmission 22 is configured to receive drive torque and transmit the drive torque to drive wheels (not shown). The transmission 22 may include, but is not limited to, an automatic transmission 22. The transmission 22 receives driving torque from the internal combustion engine 24 and / or the electric motor 26. The internal combustion engine 24 and the electric motor 26 are both coupled to the transmission 22 and are configured to selectively provide driving torque to the transmission 22. The internal combustion engine 24 may include, but is not limited to, a gasoline engine or a diesel engine, and may include any suitable size and / or configuration suitable for meeting the output and performance requirements of the hybrid vehicle 20. T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap