Boiler fuel nozzle

A burner and boiler technology, which is applied to burners, lighting and heating equipment, etc., can solve the problem that the safety and stability of the power supply system of the air supply system and the heating system cannot be guaranteed, and the gas boiler cannot meet the steam demand and cannot be fully digested. Blast furnace gas and other problems, to achieve the effect of flexible and convenient fuel switching, simple structure, and reduction of SO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

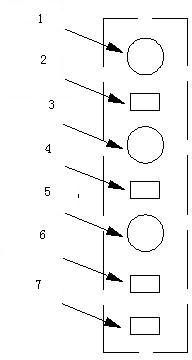

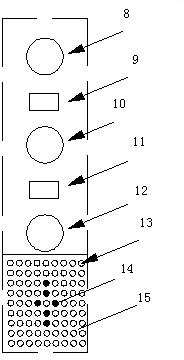

[0010] Example: figure 2 As shown, this embodiment includes a housing 15, which is provided with two pulverized coal mixing ports 10, 12, a secondary tuyere 9, and a tertiary tuyere 8, and is characterized in that the housing 15 is also provided with 6 coke ovens Gas pipe 14 and several blast furnace gas pipes 13, coke oven gas pipe 14 is arranged in the middle of several blast furnace gas pipes 13, the material of coke oven gas pipe and blast furnace gas pipe is 1Cr18Ni9Ti.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com