Multiphase online sampling device and multiphase online sampling method suitable for high-temperature hydrocarbon gas (smoke)

A sampling device and high-temperature flue gas technology, applied in the sampling device and other directions, can solve problems such as not seen, and achieve the effect of strong practicality and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

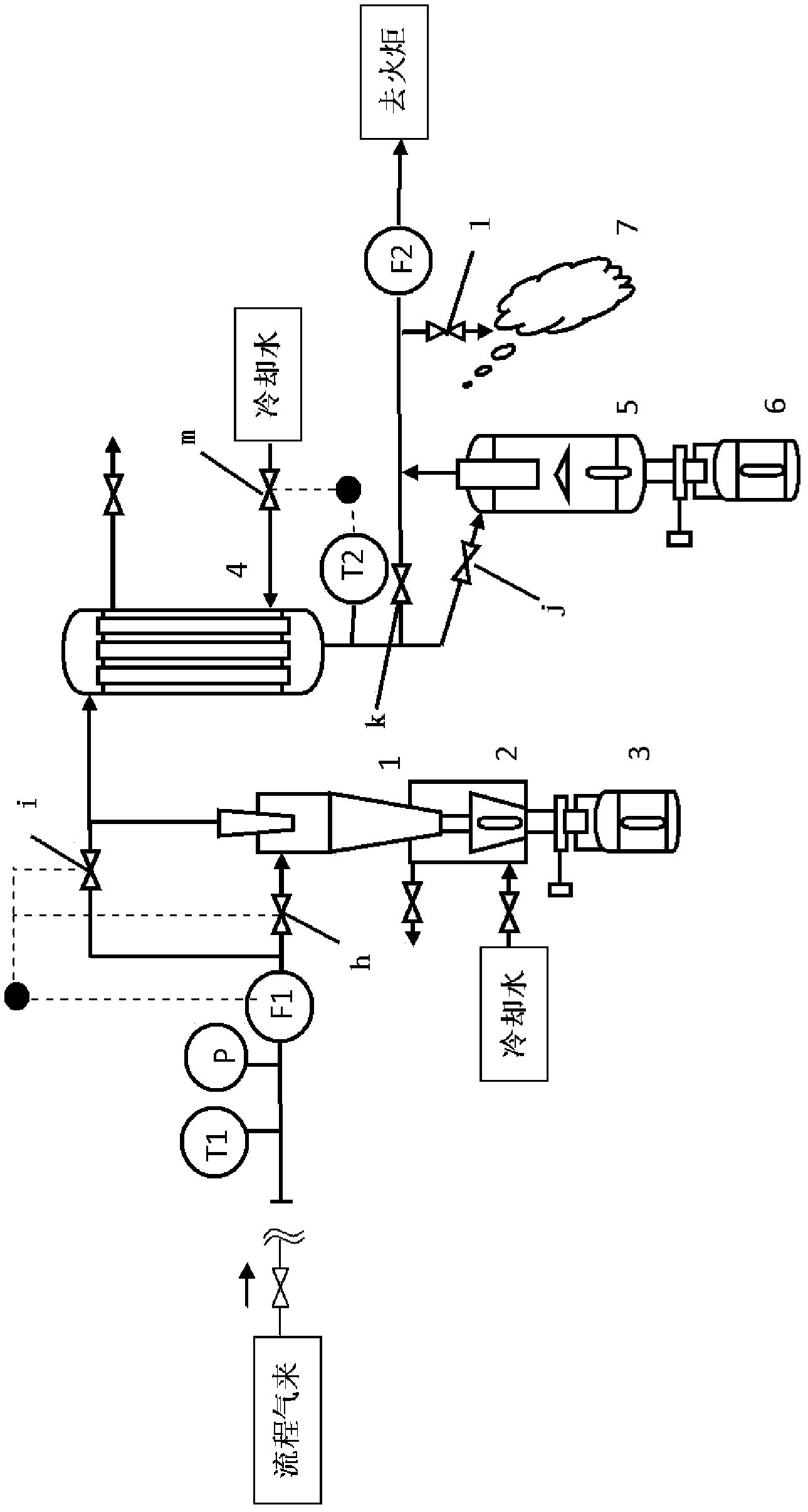

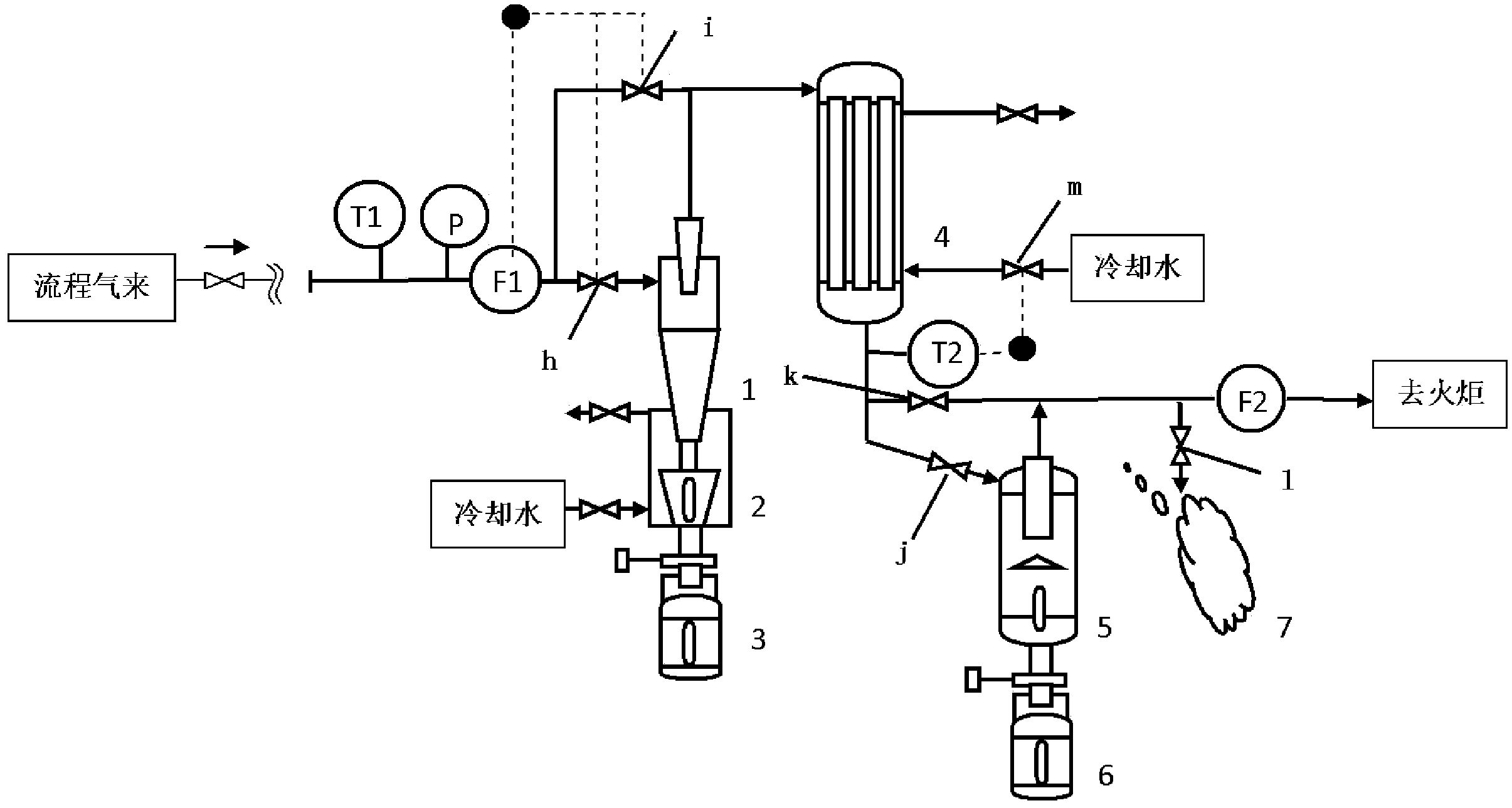

[0023] The preferred embodiment of the present invention is such as figure 1 Shown, comprise a gas-solid separator 1, condenser 4 and gas-liquid separator 5, the inlet of this gas-solid separator 1 is communicated with the hydrocarbon (smoke) gas outlet that sucks in the reaction device of catalytic cracking unit, also before the inlet A flowmeter F, a thermometer T and a pressure gauge P are provided to observe and adjust the flow rate, temperature and pressure of the sampling gas; the gas phase outlet of the gas-solid separator 1 is connected with the inlet of the condenser 4 to further reduce the gas In the present embodiment, the external cooling water of the condenser is used as the cooling medium for heat exchange; the same solid sample collection device (comprising the visible material bin 2 and the solid sampling bottle 3 at the solid phase outlet of the gas-solid separator 1) Storehouse 2 and solid sampling bottle 3 are connected by valve) to be connected so that carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com