Electric heating film

A technology of electric heating and diaphragm, which is applied in the direction of ohmic resistance heating, electric heating devices, electrical components, etc., can solve the problems of easy relaxation of resistance wires when heated, unsafe use, short circuit, etc., to facilitate automatic production, easy power control, production The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

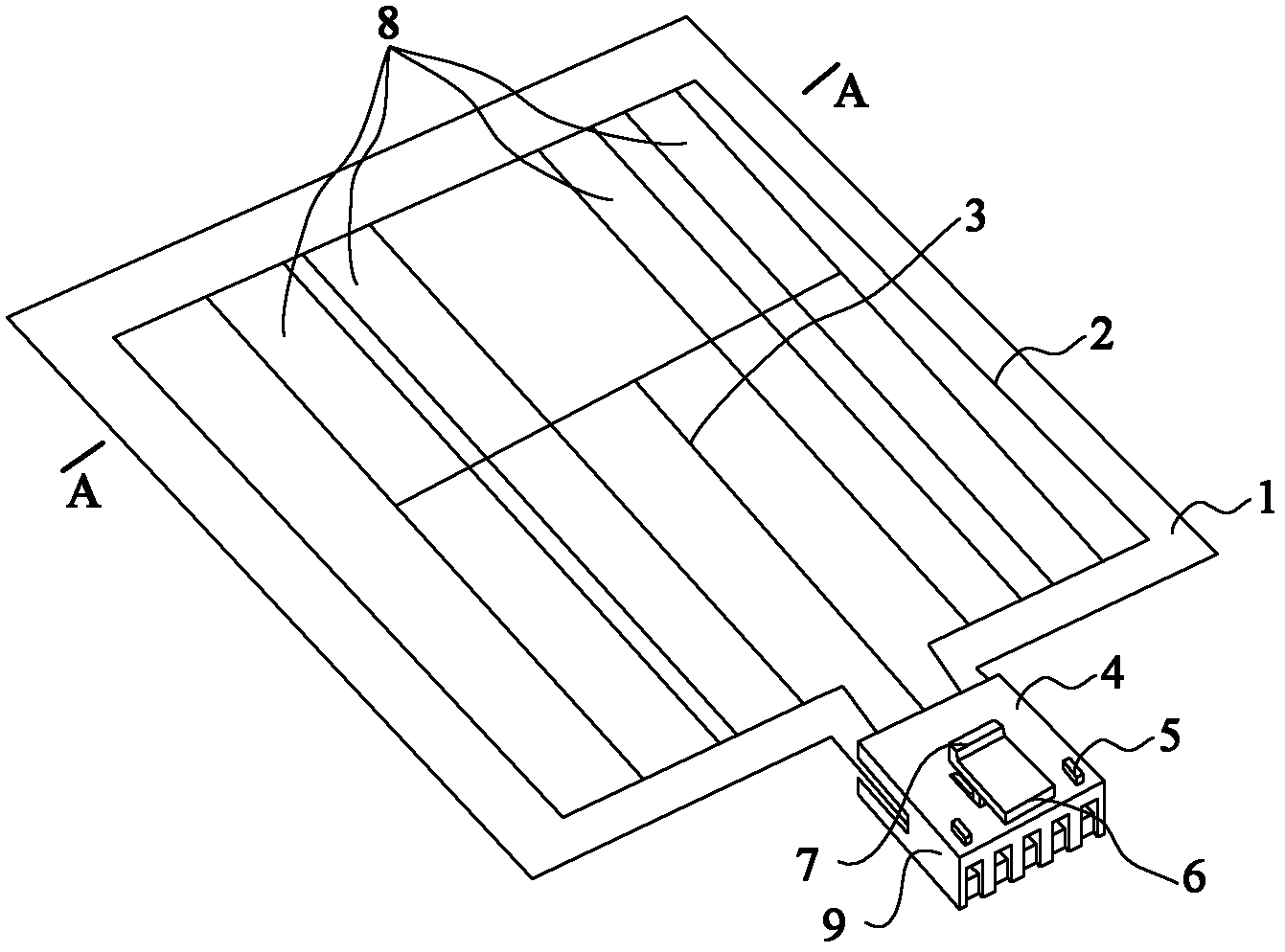

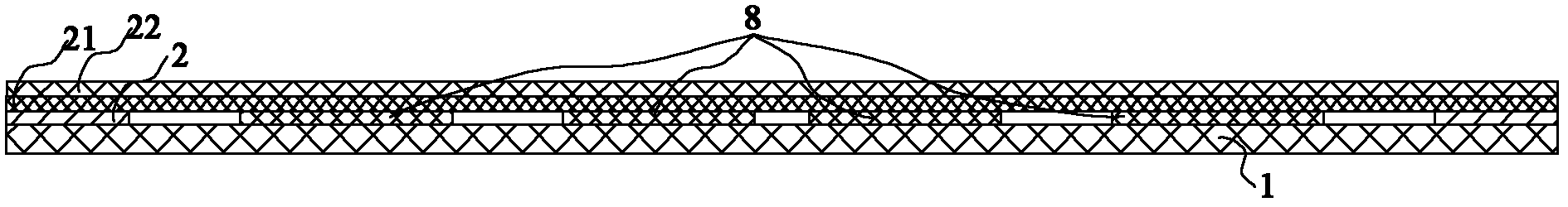

[0025] figure 1 It is a perspective view of an embodiment of the electric heating diaphragm of the present invention; figure 2 for figure 1 The A-A cross-sectional view; such as figure 1 , figure 2 As shown, the embodiment of the electric heating diaphragm of the present invention includes: a flexible diaphragm main body 1; wires are arranged on the flexible diaphragm main body 1; a heating resistance layer 8 electrically connected to the wires is laid on the flexible diaphragm main body 1; The connector 4 is electrically connected with the wire.

[0026] In the electric heating diaphragm of the above scheme, the heating resistance layer 8 electrically connected to the wire is laid on the flexible diaphragm main body 1, and the heating resistance layer 8 is made of nano-carbon resistance slurry, so that the electric heating can be effectively controlled. The thickness of the diaphragm is conducive to realizing thinning and specialization. In addition, the layout of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com