Orifice piece and atomization assembly with same

A technology of atomizing components and orifice sheets, which is applied in the field of atomizers, and can solve problems such as shortened service life, collision of liquid droplets together, and large amplitude in the central area of the orifice sheet 112.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to enable your examiner to clearly understand the content of the present invention, the following descriptions are provided together with the accompanying drawings, please refer to them.

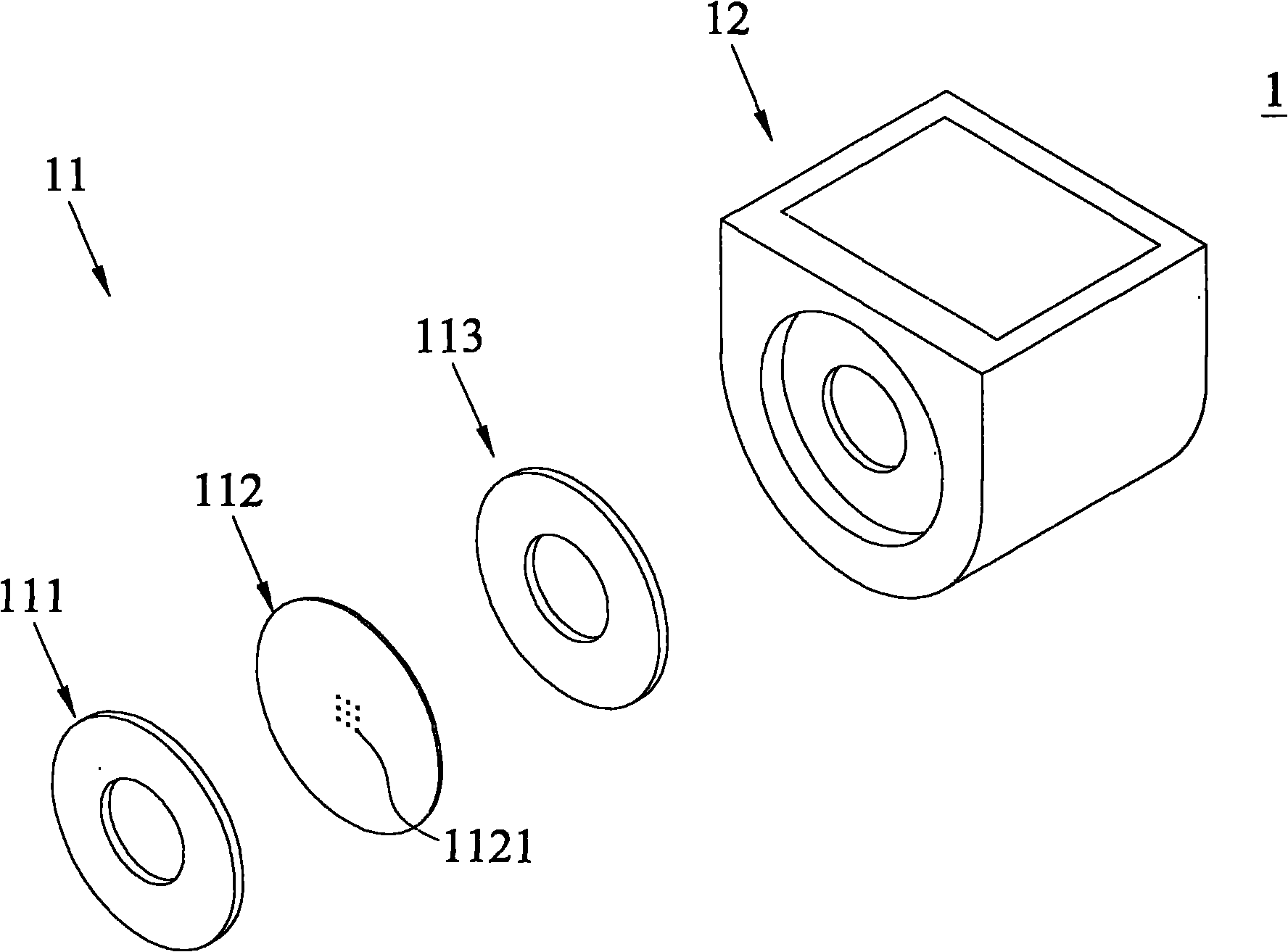

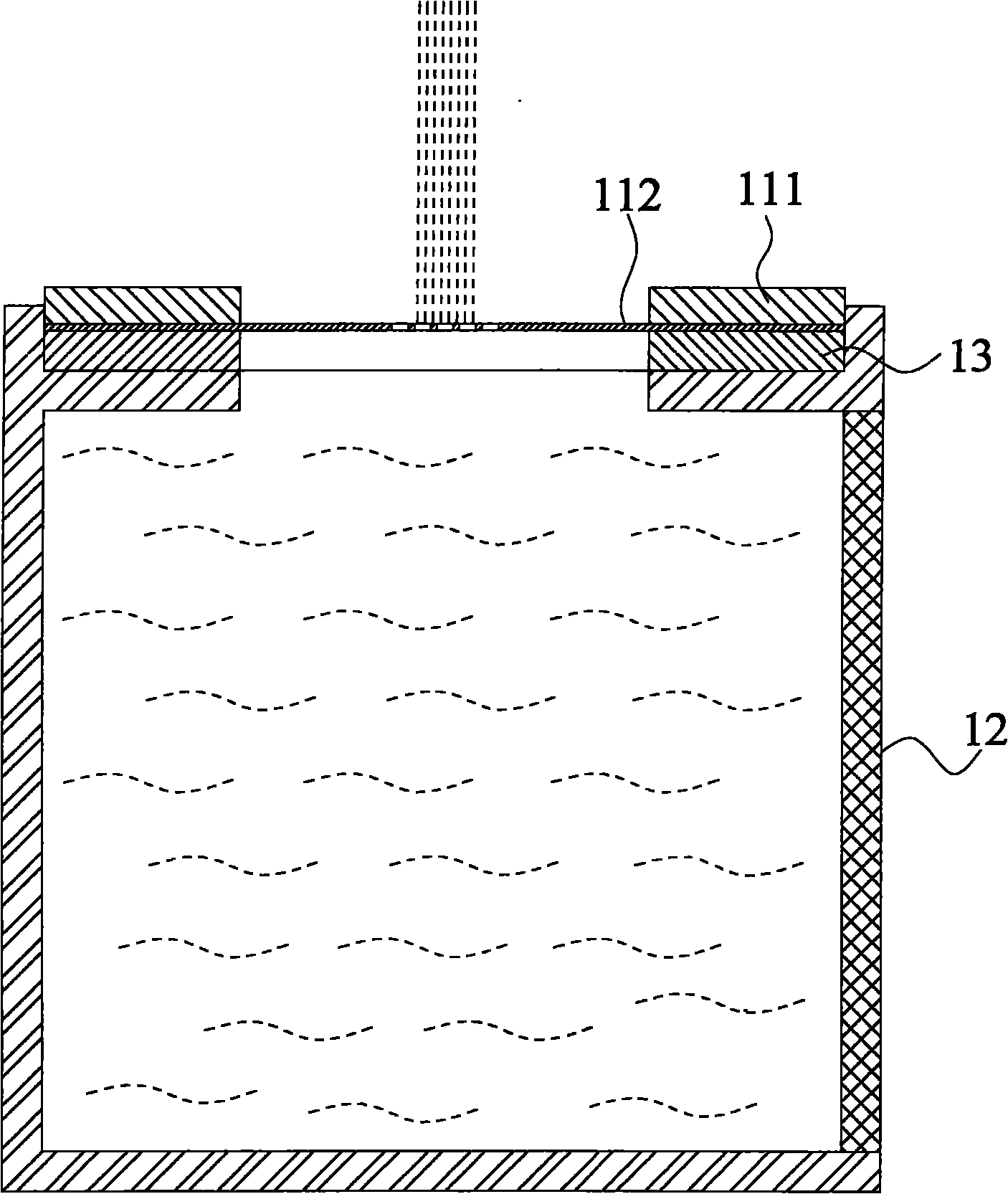

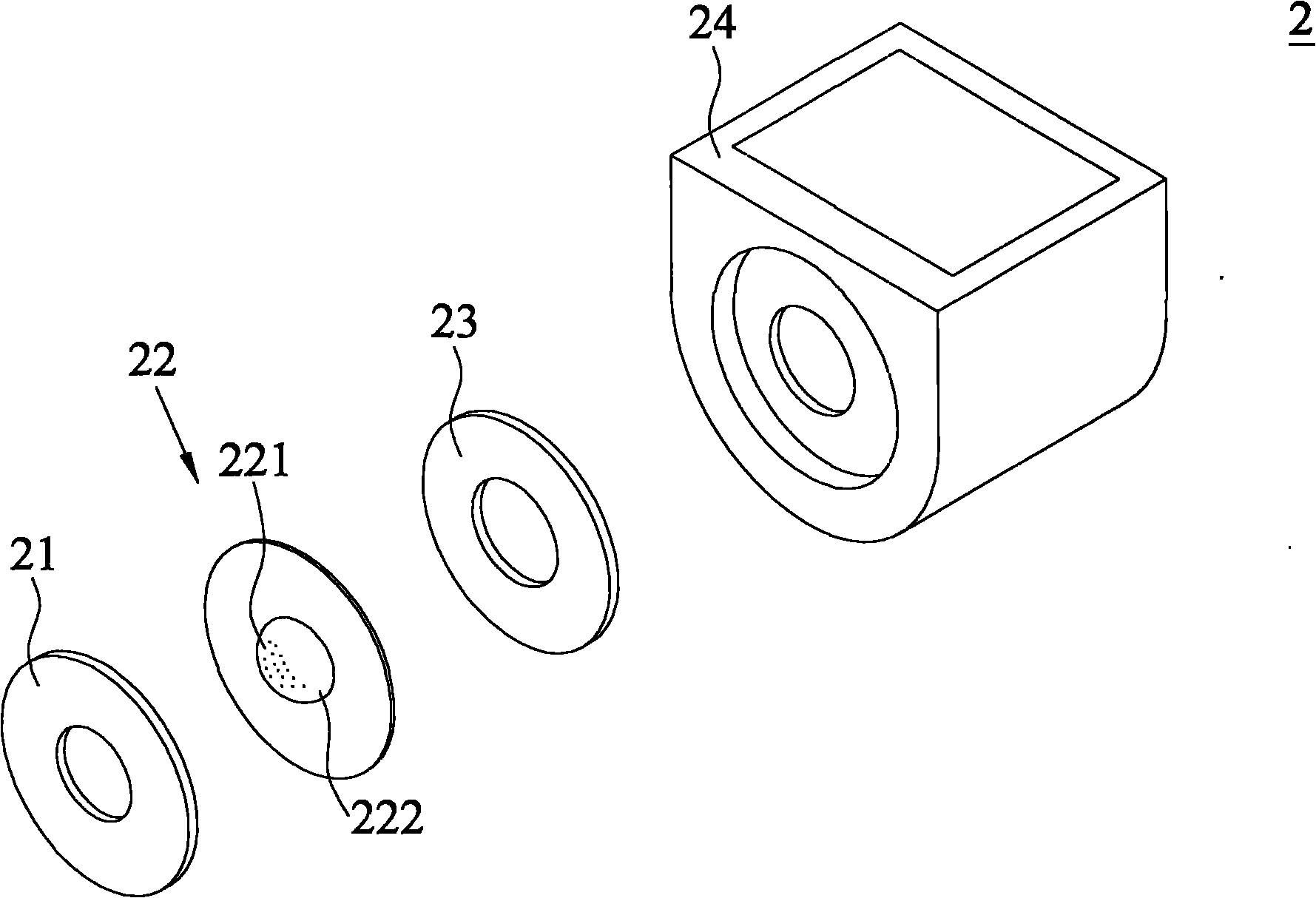

[0064] see Figure 7A , Figure 7B , Figure 8 and Figure 9 As shown, it is an exploded view, a schematic diagram of the nozzle hole sheet, a cross-sectional view and a schematic diagram of the nozzle hole sheet of the first embodiment of the nozzle hole sheet of the present invention and the atomization assembly using it. In the figure, the atomization assembly 3 is disposed on one side of a cavity 34 and includes a piezoelectric ring 31 , an orifice 32 and a braking ring 33 .

[0065] The piezoelectric ring 31 can be made of piezoelectric ceramics made of lead zirconate titanate material, and has an outer diameter 311 and an inner diameter 312 .

[0066] The brake ring 33 is a metal ring with an outer diameter 331 and an inner diameter 332 , and is disposed on one side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com