Non-toxic biological anti-fouling resistance reducing composite coating, preparation method for composite coating and anti-fouling resistance reducing treatment method for base material

A composite coating and bio-antifouling technology, applied in antifouling/underwater coatings, coatings, biocide-containing paints, etc. Resistivity and other issues, to achieve low production costs and maintenance costs, reduce adverse effects, and enhance the effect of improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

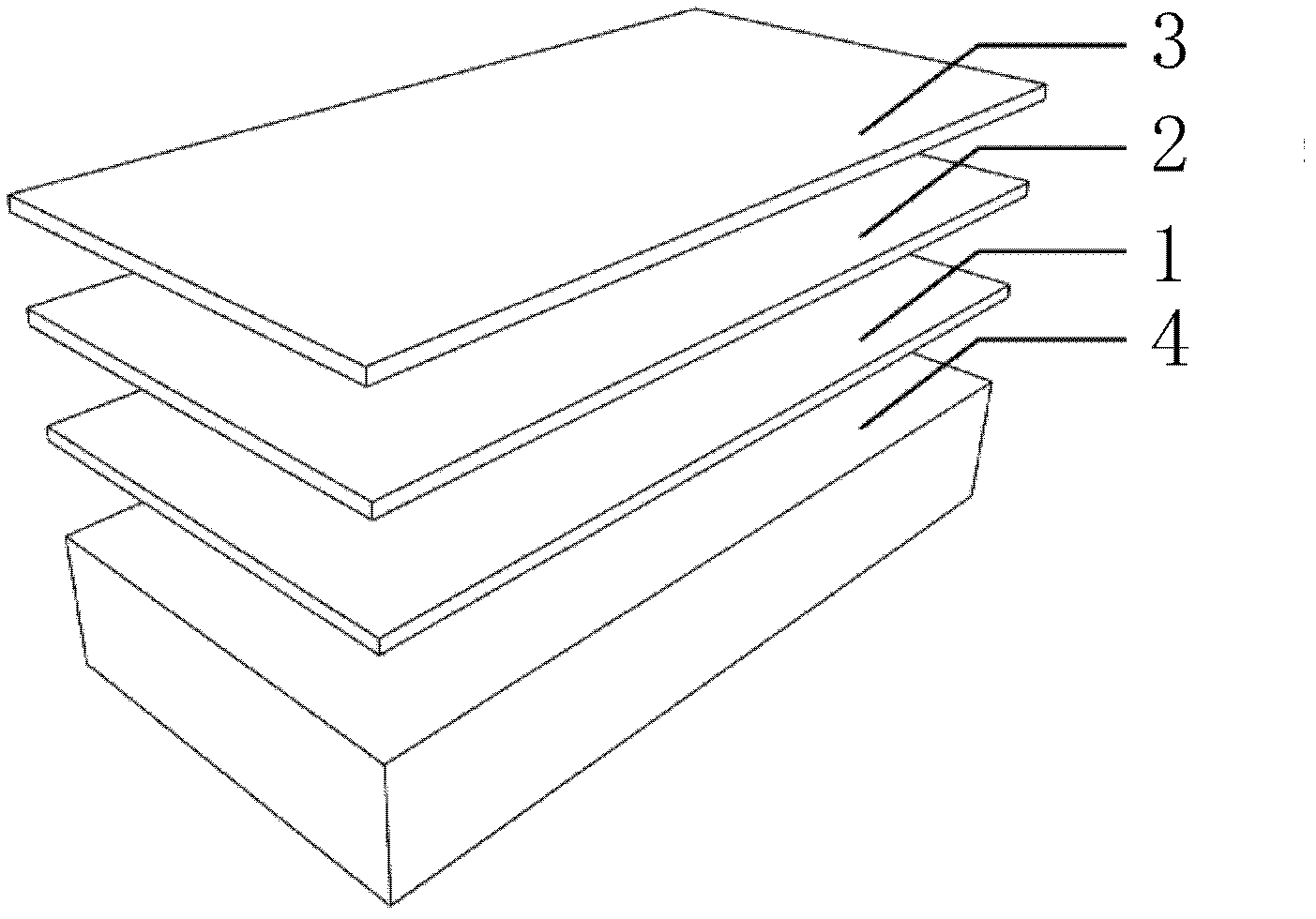

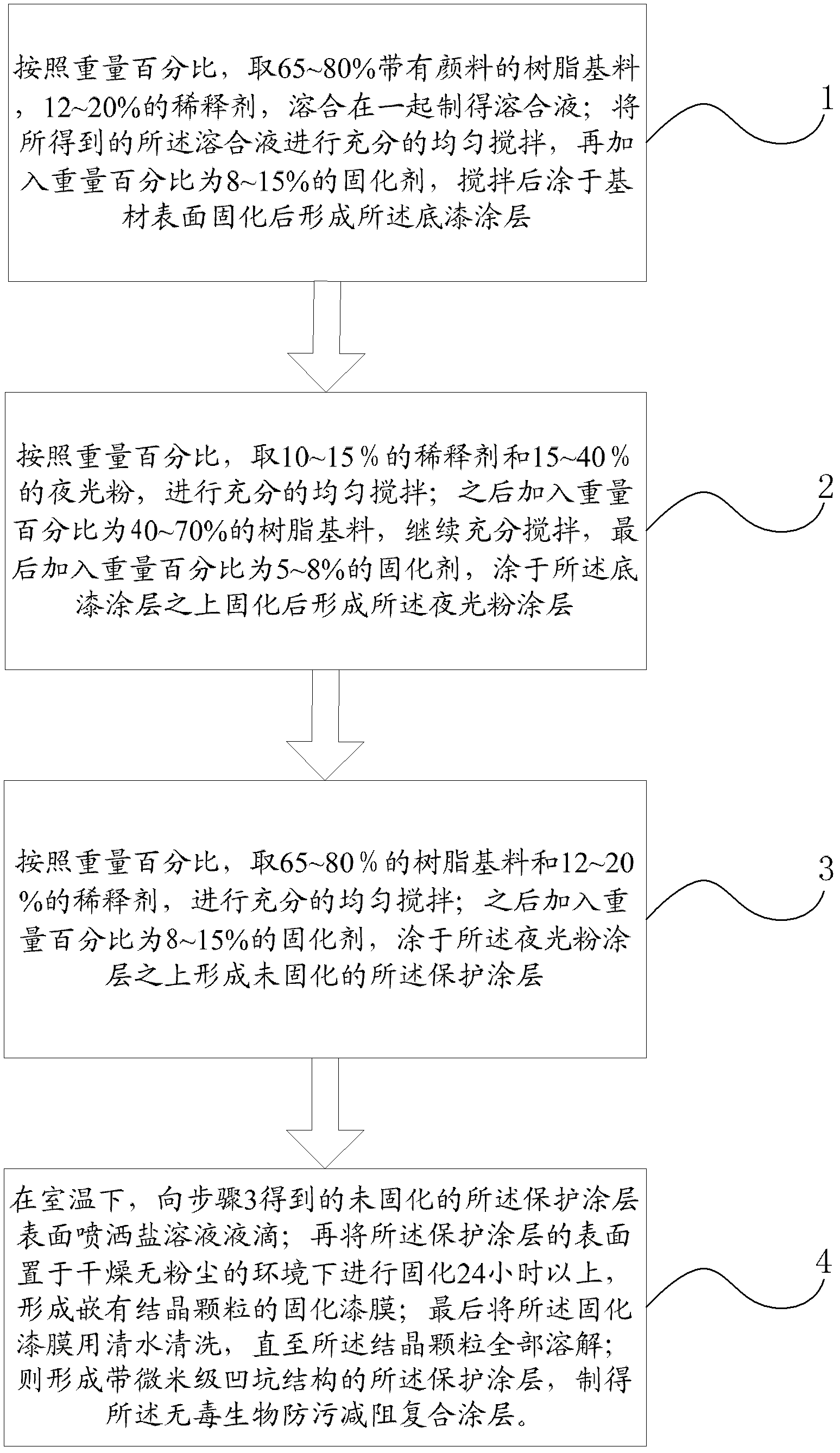

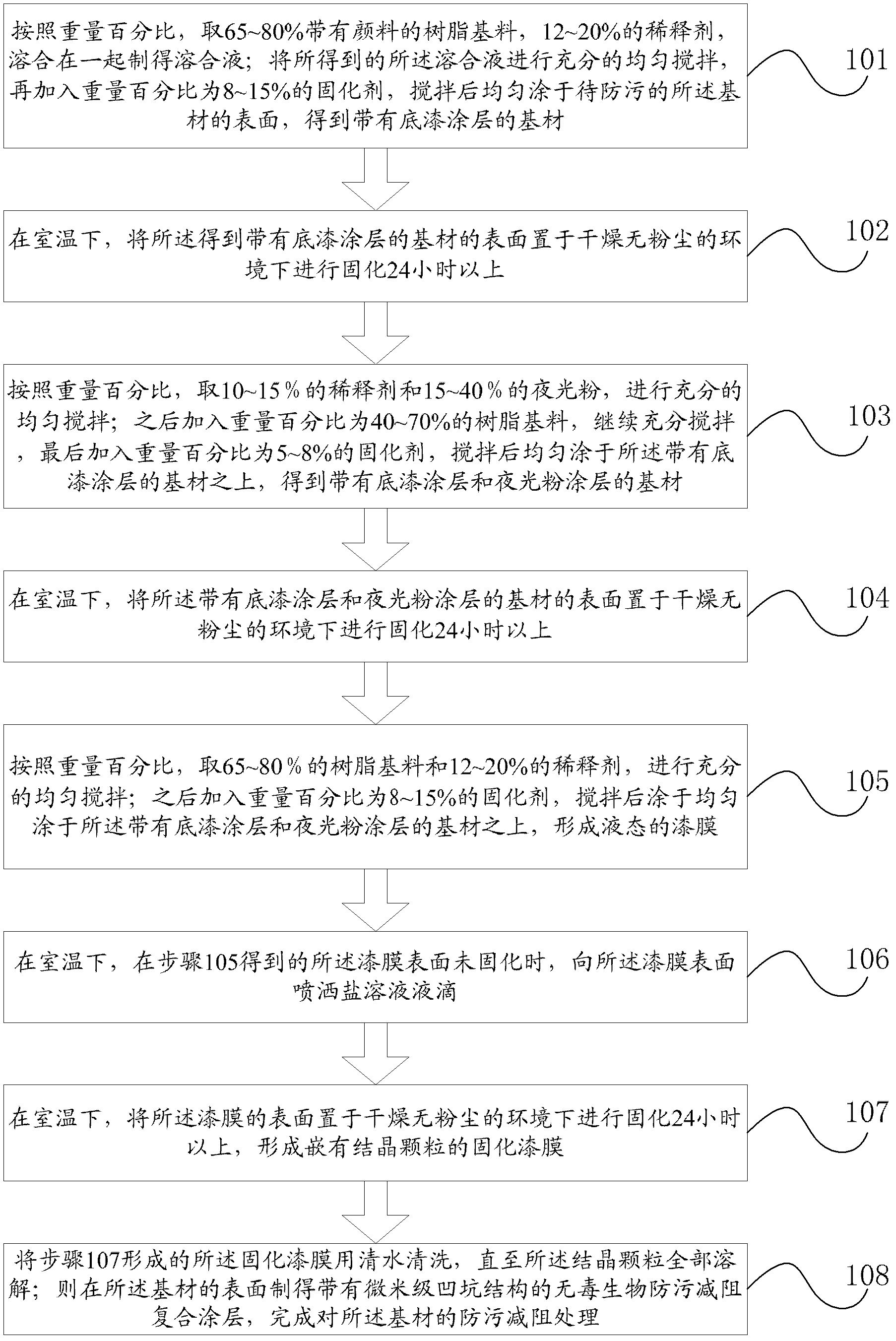

Embodiment 1

[0068] A non-toxic biological anti-fouling and drag-reducing composite coating according to the present invention comprises epoxy resin with white pigment, organic silicon resin with light transmission, diluent, luminous powder, and curing agent. Configure (1) white primer coating respectively, according to the percentage by weight of each component: 75% of epoxy resin with white pigment, 15% of diluent, and 10% of curing agent; (2) luminous powder coating, Percentage by weight of each component is: 62% of silicone resin, 13% of thinner, 19% of luminous powder, 6% of curing agent; (3) low surface energy protective coating, according to percentage by weight of each component: : Silicone resin 77%, thinner 14%, curing agent 8%. The luminous powder contains non-toxic and non-radiative alkaline earth aluminosilicate excited by rare earth elements. The non-toxic biological anti-fouling and drag-reducing composite coating of this embodiment has a good anti-fouling and drag-reducing...

Embodiment 2

[0070] Another non-toxic biological anti-fouling and drag-reducing composite coating according to the present invention includes polyurethane resin with white pigment, fluorocarbon resin with light transmission, diluent, luminous powder, and curing agent. Respectively configure (1) white primer coating, according to the weight percentage of each component: 65% of polyurethane resin with white pigment, 20% of diluent, 15% of curing agent; (2) luminous powder coating, according to The components by weight percentage are: 55% of fluorocarbon resin, 10% of diluent, 30% of luminous powder, and 5% of curing agent; (3) low surface energy protective coating, according to the weight percentage of each component: Fluorocarbon resin 80%, diluent 12%, curing agent 8%. The luminous powder contains non-toxic and non-radiative alkaline earth aluminosilicate excited by rare earth elements. The non-toxic biological anti-fouling and drag-reducing composite coating of this embodiment has a good...

Embodiment 3

[0072] Another non-toxic biological anti-fouling and drag-reducing composite coating according to the present invention includes acrylic resin with white pigment, fluorosilicone resin with light transmission, diluent, luminous powder, and curing agent. Configure respectively (1) white primer coating, according to the percentage by weight of each component: 70% of acrylic resin with white pigment, 18% of thinner, 12% of curing agent; (2) luminous powder coating, according to The components by weight percentage are: 67% of fluorosilicone resin, 10% of diluent, 18% of luminous powder, and 5% of curing agent; (3) low surface energy protective coating, according to the weight percentage of each component: Fluorosilicone resin 65%, diluent 25%, curing agent 10%. The luminous powder contains non-toxic and non-radiative alkaline earth aluminosilicate excited by rare earth elements. The non-toxic biological anti-fouling and drag-reducing composite coating of this embodiment has a good...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com