Antibacterial microporous ceramic and manufacturing method thereof

A microporous ceramic and microporous technology is applied in the field of drinking water purification, which can solve the problems of excessive bacterial content and inability to effectively remove bacteria, and achieve the effects of simple manufacturing method, preventing excessive bacteria in effluent, and good bacteriostatic and bactericidal properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

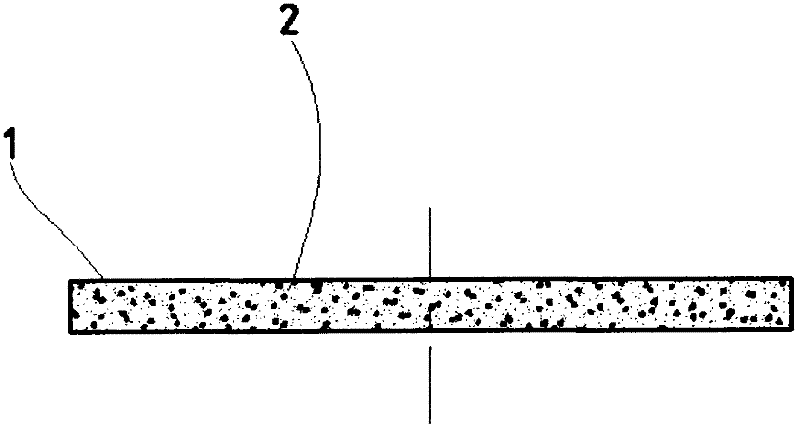

[0031] See figure 1 , a circular plate-shaped antibacterial microporous ceramic 1, the micropores of which contain AgO solid particles 2, the filtration accuracy of the antibacterial plate-shaped microporous ceramic 1 is 1 micron to 20 microns, and the antibacterial plate-shaped microporous ceramic 1 The main raw material is diatomaceous earth, which has hydrophilic properties.

[0032] The manufacturing steps of antibacterial plate-shaped microporous ceramics 1 are:

[0033] Step 1. Use 90 volumes of powdered diatomite, 5 volumes of clay, 5 volumes of lime and water to prepare a slurry. The particle size of the powder material is controlled to be 1 micron to 20 microns suitable for the filtration accuracy after making. The disc-shaped blank is made by grouting forming method, then dried, and then sintered at a high temperature of 900 ° C to 1100 ° C;

[0034] Step 2. Soak the sintered microporous ceramics in a silver nitrate solution with a concentration of 0.15mol / L, make ...

Embodiment 2

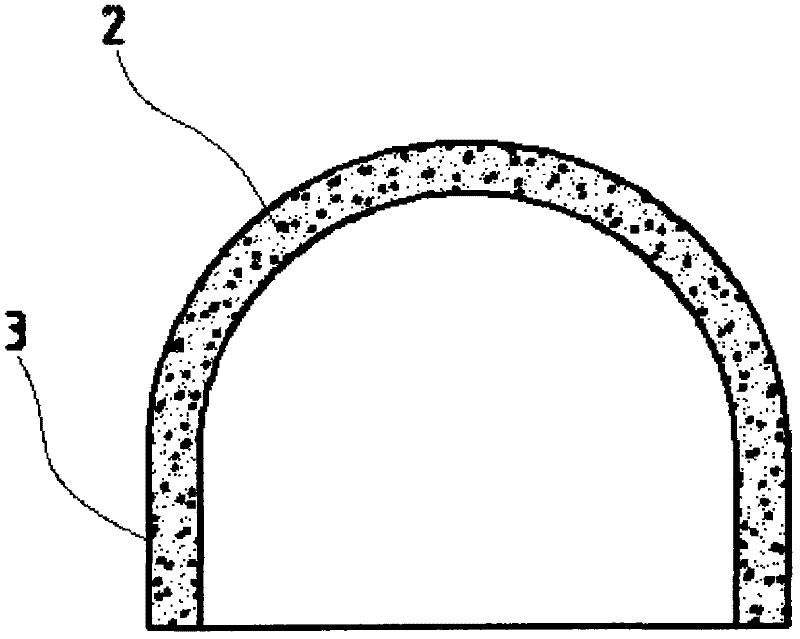

[0039] See figure 2 , a hemispherical antibacterial microporous ceramic 3, the micropores of which contain AgO solid particles 2, the hemispherical antibacterial microporous ceramic 3 has a filtration accuracy of 1 micron to 50 microns, and the hemispherical antibacterial microporous ceramic 3 mainly The raw material is diatomaceous earth, which has hydrophilic properties.

[0040] The manufacturing steps of hemispherical antibacterial microporous ceramics 3 are:

[0041] Step 1. Use 90 parts of powdered diatomite, 5 parts of clay, 5 parts of lime and water to prepare a slurry. The particle size of the powder material is controlled so that the filtration accuracy is 1 micron to 50 microns. It is made by grouting. Form a hemispherical billet, dry it in the air, and then sinter at a high temperature of 900°C to 1100°C;

[0042] Step 3~step 5 are the same as embodiment 1.

Embodiment 4

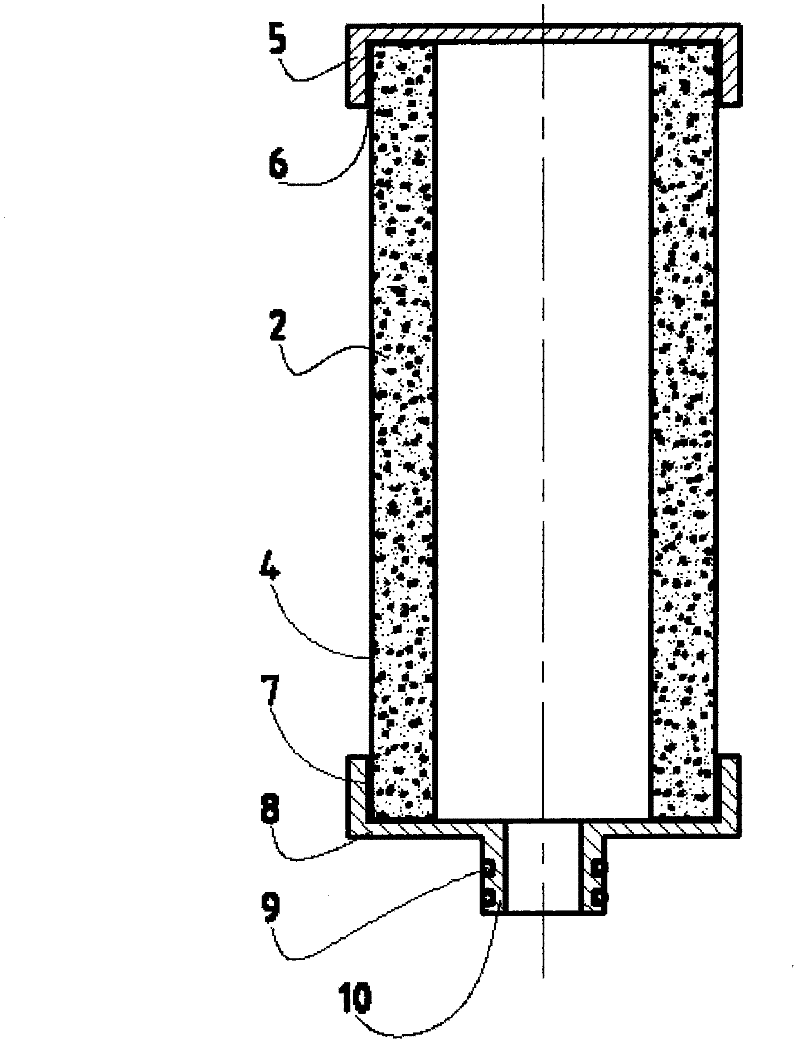

[0044] See image 3, a circular tubular antibacterial microporous ceramic filter element, comprising a circular tubular antibacterial microporous ceramic 4, a stuffy cover 5, a joint 8 and a sealing ring 9; the end face of one end of the circular tubular antibacterial microporous ceramic 4 and near the The side of the end face is bonded, sealed, and fixedly connected with food hygiene-grade adhesive 6 and stuffy cover 5, and the end face of the other end and the side near the end face are bonded, sealed, and fixedly connected with food hygiene-grade adhesive 7 and joint 8. The joint 8 is provided with an outlet pipe 10, and the outlet pipe 10 is provided with a groove capable of assembling a sealing ring 9, and the sealing ring 9 is housed in the groove; AgO solid particles 2 are contained in the micropores of the circular tubular antibacterial microporous ceramics 4; The filtration precision of the tubular antibacterial microporous ceramics 4 is 20 microns, which has hydrophi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| filtration accuracy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com