A process for simultaneously producing two environment-friendly rubber filling oils

An environmentally friendly rubber and oil filling technology, which is applied in the petroleum industry, processing hydrocarbon oil, etc., to meet the needs, small investment in equipment, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

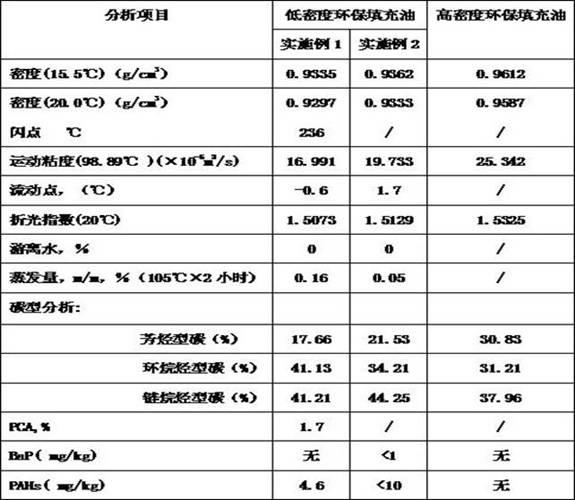

Examples

Embodiment 1

[0025] Use Zhonghai Asphalt (Taizhou) Co., Ltd. as the raw material, N-methylpyrrolidone as the solvent, and the solvent-to-oil ratio (volume ratio, referring to the volume ratio of the solvent N-methylpyrrolidone to the raw material minus the third-line distillate) 1.0 to 2.0 and mix evenly. Place in a settling tank for constant temperature settling, the settling temperature is 40-60°C, and the residence time is 30 minutes to 2 hours to obtain the upper layer liquid and the lower layer liquid. Aromatic oil, the upper liquid is distilled under reduced pressure at 1 Torr to 100 Torr to recover the solvent N-methylpyrrolidone to obtain primary raffinate oil.

[0026] Then use primary raffinate oil as raw material, N-methylpyrrolidone as solvent, mix evenly with agent-oil ratio (volume ratio) 1.0-2.0, place in settling tank for constant temperature settling, settling temperature 50-70°C, residence time 30 minutes After 2 hours, the upper layer liquid and the lower layer liquid ar...

Embodiment 2

[0029] Use the minus three lines of Zhonghai Asphalt (Taizhou) Co., Ltd. as raw material, N-methylpyrrolidone as solvent, mix evenly with agent-oil ratio (volume ratio) 1.0-2.0, place in a settling tank for constant temperature settling, settling temperature 40-60°C, The residence time is 30 minutes to 2 hours to obtain the upper layer liquid and the lower layer liquid. The upper layer liquid is distilled under reduced pressure at 1 Torr to 100 Torr to recover the solvent to obtain a raffinate oil, and the lower layer liquid is 1 Torr to 100 Torr to recover the solvent after vacuum distillation to obtain a raffinate oil. The oil is highly aromatic oil.

[0030] Then use primary raffinate oil as raw material, dimethyl sulfoxide as solvent, mix evenly with agent-oil ratio (volume ratio) 1.0-4.0, place in a settling tank for constant temperature settling, settling temperature 70-90°C, residence time 30 minutes After 2 hours, the upper layer liquid and the lower layer liquid are o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com