Novel power transmission mechanism of all-hydraulic drill

A power transmission mechanism and full hydraulic technology, applied in rotary drilling rigs, mechanical equipment, earthwork drilling and mining, etc., can solve the problems of reducing the overall volume of the gearbox, occupying a large space and weight, heat and wear, etc. The conversion is convenient and reliable, the sealing performance is good, and the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

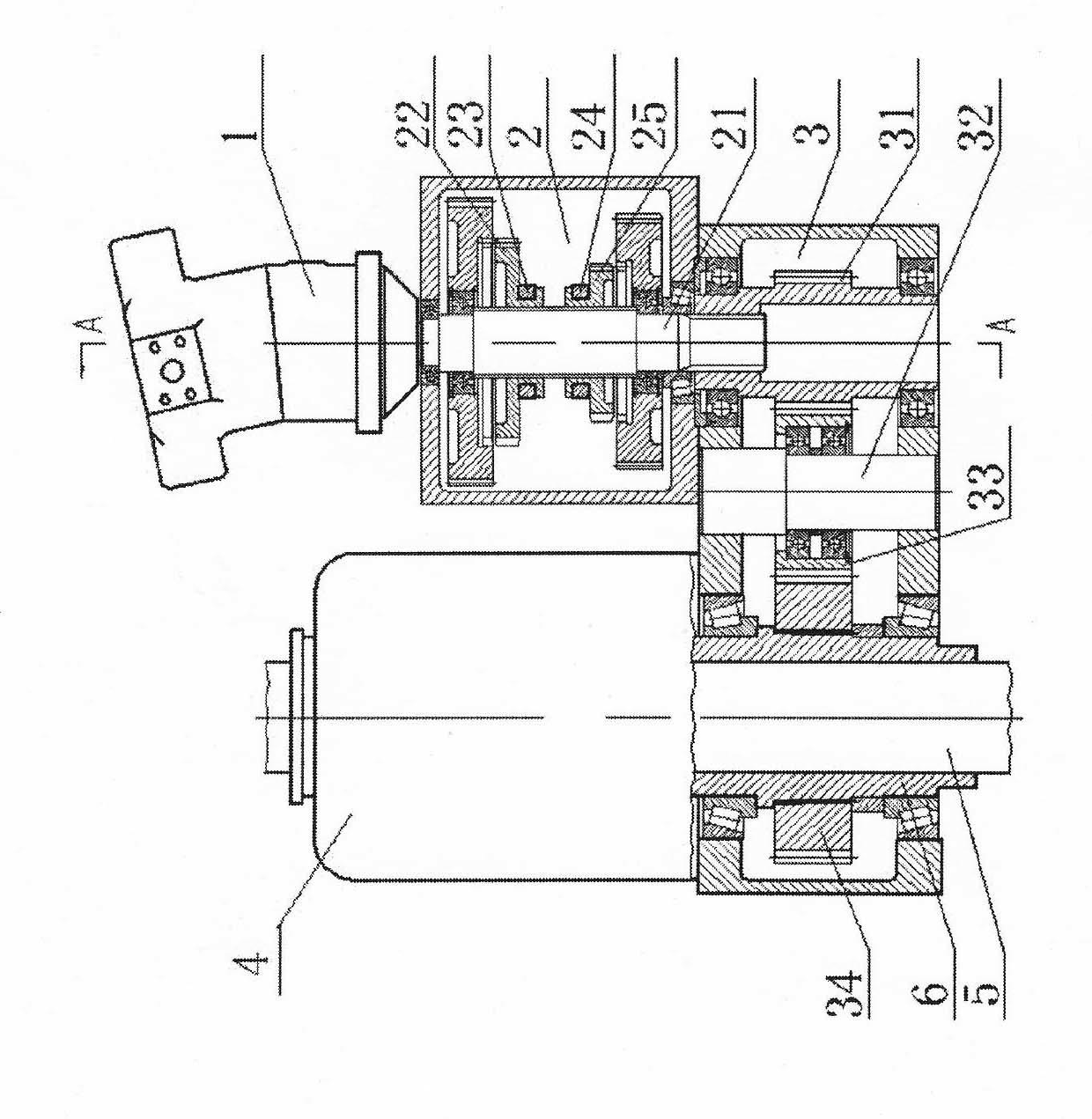

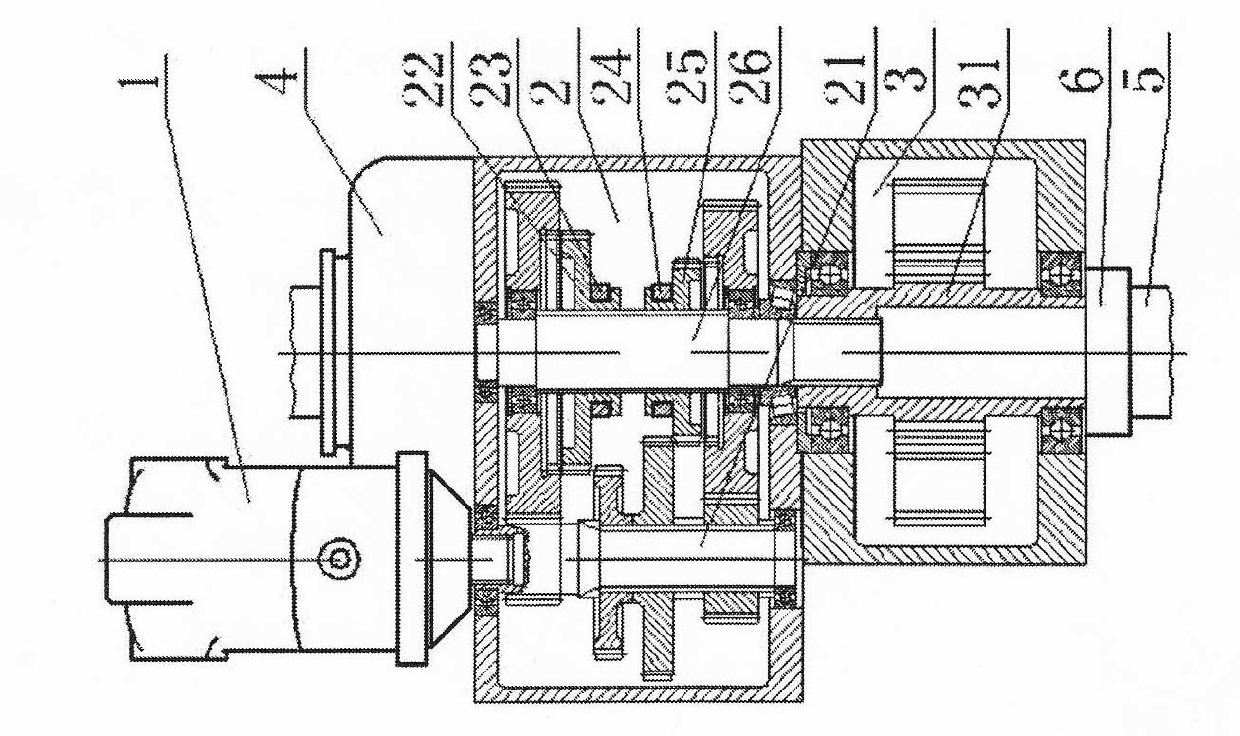

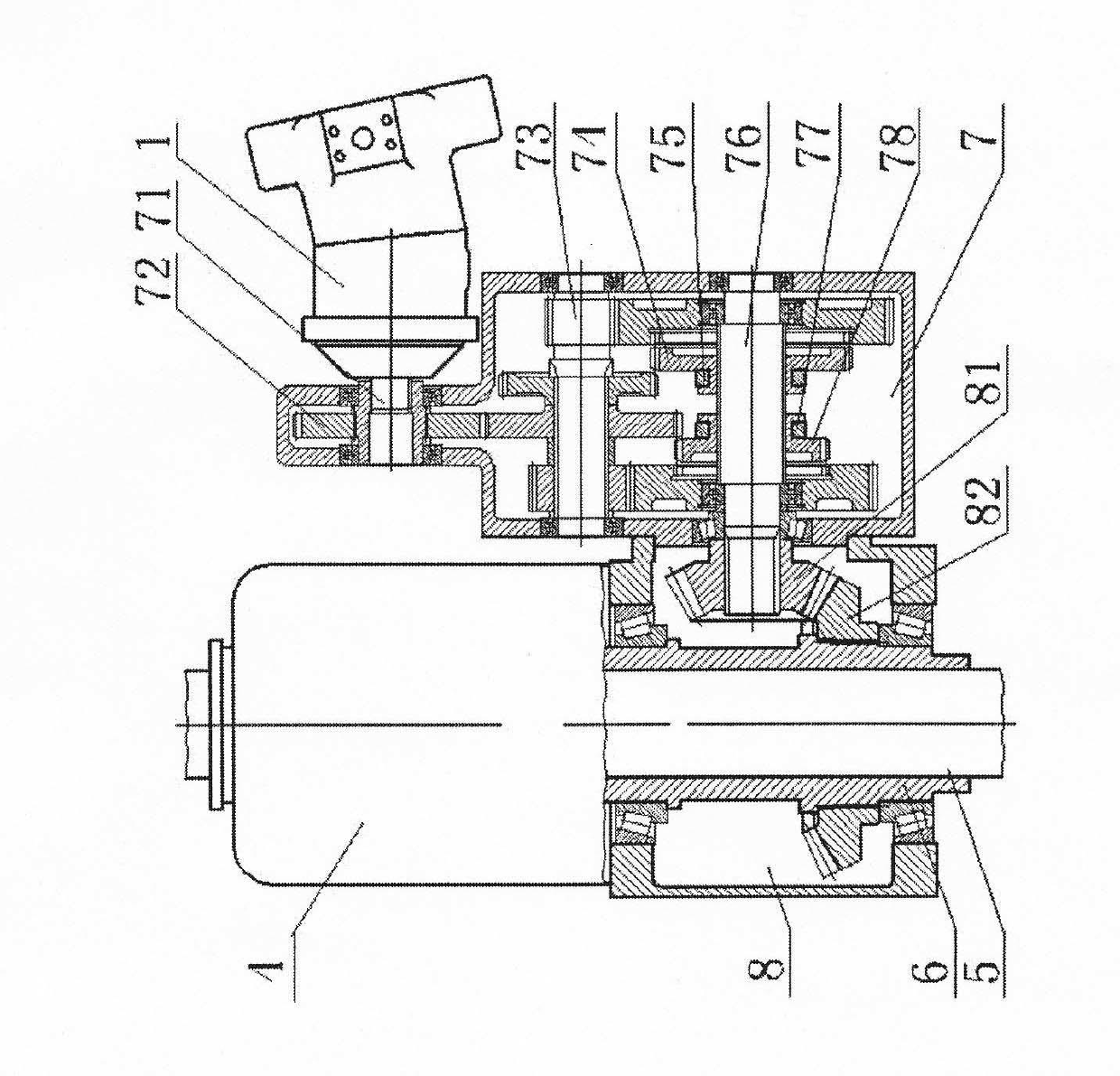

[0022] like image 3 , 4 Shown: a new type of full hydraulic drilling rig power transmission mechanism, including hydraulic motor 1, gearbox 7, gearbox 8, power head 4, drill pipe 5 and drill pipe sleeve 6, hydraulic motor 1 is located on gearbox 7, gearbox 7 includes starting gear shaft 71, starting gear 72, active shifting shaft 73, right shifting gear 74, right shifting fork 75, passive shifting shaft 76, left shifting fork 77 and left shifting gear 78. Gear shaft 71, active transmission shaft 73 and passive transmission shaft 76 are all installed in the gearbox 7, and their axes are all perpendicular to the axis of drill rod 5, and starting gear 72 is installed on the starting gear shaft 71, and is connected with driving transmission shaft 73 The gears on the gear mesh, the right shift gear 74 and the left shift gear 78 are installed on the passive shift shaft 76, the right shift fork 75 and the left shift fork 77 are respectively located on the right shift gear 74 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com