Decoking device for coal-fired boiler

A technology of coal-fired boilers and translational devices, which is applied in the direction of lighting and heating equipment, etc., can solve the problems of coking machines that are difficult to swing and hit coke in a large range, the effect of coke hitting is not ideal, and the linkage control and coordination are difficult, so as to improve the coke hit and remove Focus effect, improved operational flexibility, improved effectiveness and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

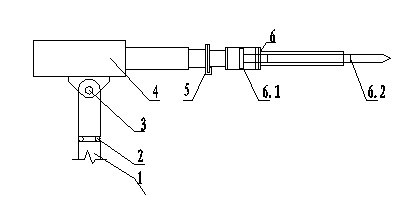

[0041] Embodiment 1: see figure 1 , the decoking device for a coal-fired boiler of the present invention comprises a support vertical bar 1, the top of which is biased by a movable hinge support 3 of a lug to support a coking cross arm 4, and a slidable counterweight is arranged at the rear end of the coking cross arm 4 (in the figure Not shown, it can also be an adjustable diagonal tie rod), the front end is connected to the connecting flange 5, and the assembly connection is connected with the coking drill bit 6.2 of the valve-controlled cylinder 6.1 to form an impact vibration coking head 6. Among them, there is a plane rotating bearing 2 and a movable hinge support 3 on the top of the support vertical rod, and the two work together to make the coke hitting cross arm 4 move arbitrarily 360 degrees according to the support vertical rod, which is convenient for aligning with the coking hole on the furnace wall , so that the focus block can be fine-tuned when focusing. Of cou...

Embodiment 2

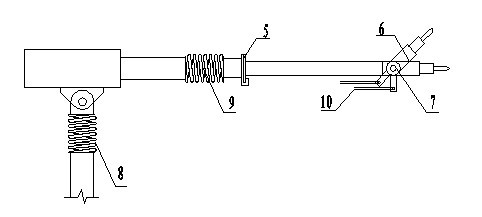

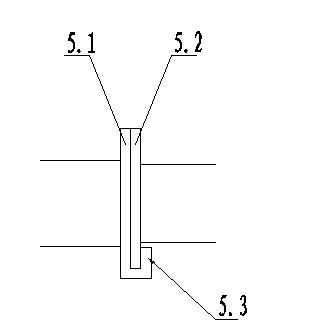

[0044] Example 2: see figure 2 -4. As mentioned above, there are spring dampers 8 and 9 respectively between the upper part of the supporting vertical bar (below the hinge fulcrum), and between the focusing cross arm and the shock and vibration focusing head 6 (other damping devices can also be used). Shock vibration acts as a shock absorber. The connecting flange 5 adopts a quick-installed flange that only needs one screw connection, and the quick-installed flange has an adjustable arc-shaped groove 5.4 on the upper part of one flange 5.1 (which can realize the angle rotation of the front end, and the other flange also has this arc-shaped groove, the rotation angle is larger), and the lower part has an arc-shaped hook 5.3 protruding from the plane. This structure only needs to insert another piece of connecting flange into the arc-shaped hook, and tighten the screws in the upper arc-shaped groove to achieve the connection. , can realize the fast connection of two flanges. ...

Embodiment 3

[0046] Embodiment 3: see Figure 5 , 6 , as mentioned above, wherein the worm gear 12 and the worm screw 11 assembly are arranged between the hinge of the focusing cross arm 4 and the support vertical rod 1, and the pitch angle of the focusing cross arm can be automatically adjusted by the rotation of the worm screw. Wherein the worm wheel 12 is driven by the assembly of the spline shaft 13 and the shaft sleeve 14, and realizes the warping of the focusing cross arm through the separable / combined concave-cam groups 15.1 and 15.2 respectively arranged on the spline shaft sleeve and the focusing cross arm rotating shaft 16 Kinematic coupling and disengagement. The worm drive can be driven by rotary power such as a geared motor, a rotary oil cylinder, and a rotary cylinder. This structure enables the coupling to drive the focusing arm to move up and down, and the focusing arm can freely move up and down after separation. That is, the transmission is disengaged after the coking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com