Method for real-time measurement of torch flow rate of torch discharge system based on torch videos

A torch discharge, real-time measurement technology, applied in the direction of measuring flow/mass flow, measuring device, liquid/fluid solid measurement, etc., can solve the problems of flow meter damage, uncertain flame medium, and poor flow measurement of torch discharge. Achieve the effects of improving recycling efficiency, reducing emissions, and improving regional environmental quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

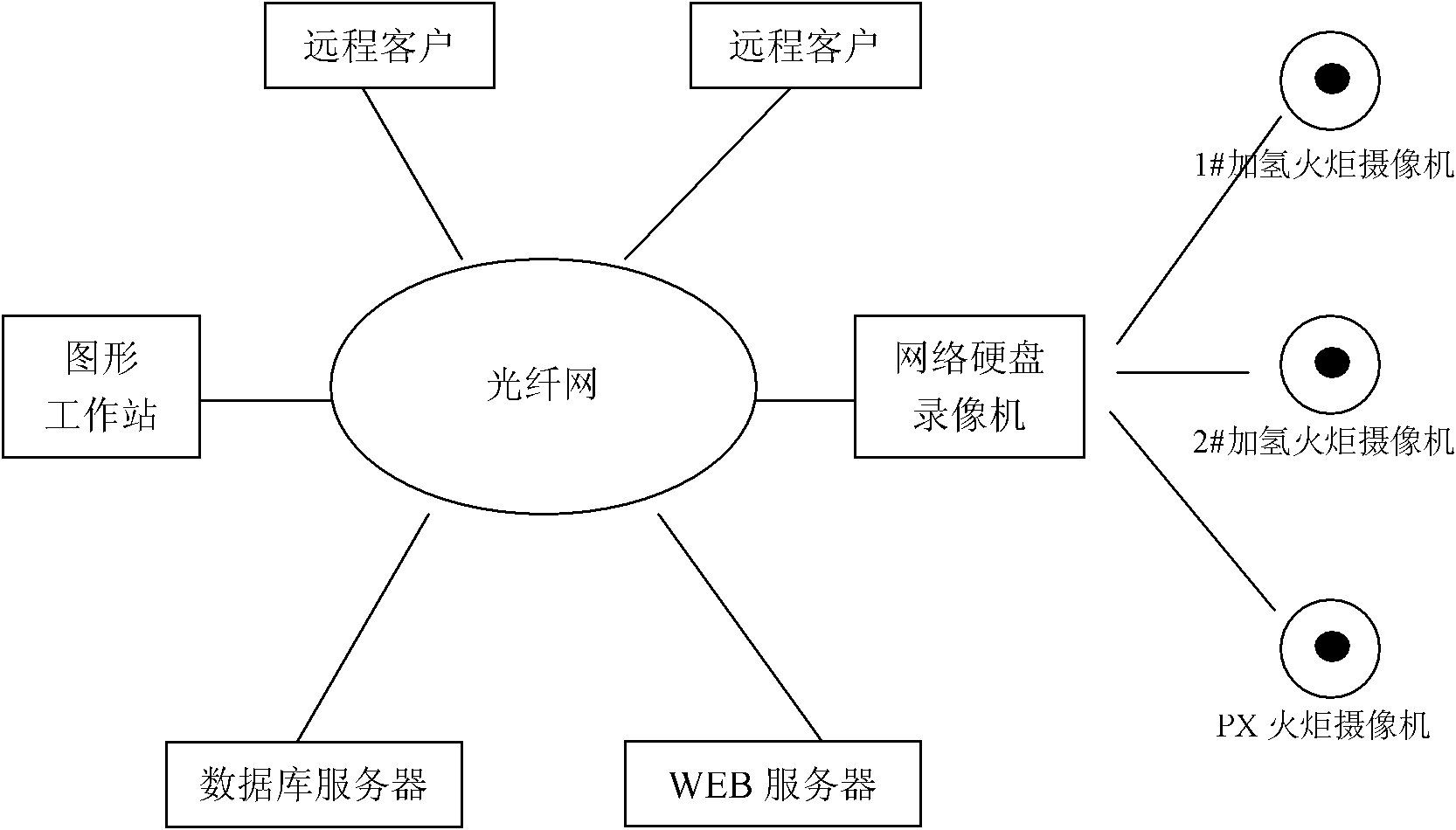

[0021] The present invention measures the actual flare discharge data by monitoring the flame size in the flare discharge system, such as figure 1 In the present invention, the flame video of the torch discharge system is obtained through the network hard disk video recorder, and transmitted from the network to the rear graphics workstation for processing, the processed data is stored in the database server, and the data is sent to the remote user through the WEB server. It includes the following steps:

[0022] 1) Set up a network hard disk video recorder to collect the flame video of the torch discharge system, and transmit the collected video to the graphics workstation;

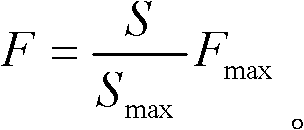

[0023] 2) The graphics workstation processes each frame of the captured video, including image preprocessing and extraction of characteristic points of the flame target; after the characteristic points of the flame target are extracted, the irregular graphics enclosed by the characteristic points are calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com