Intelligent spot inspection periodical repair instrument

A point-checking and repairing, intelligent technology, applied in the field of smart meters, can solve problems such as inconvenience in use and imperfect functions of point-checking and repairing instruments, and achieve the effect of reducing the number of charging times, avoiding back and forth, and improving flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

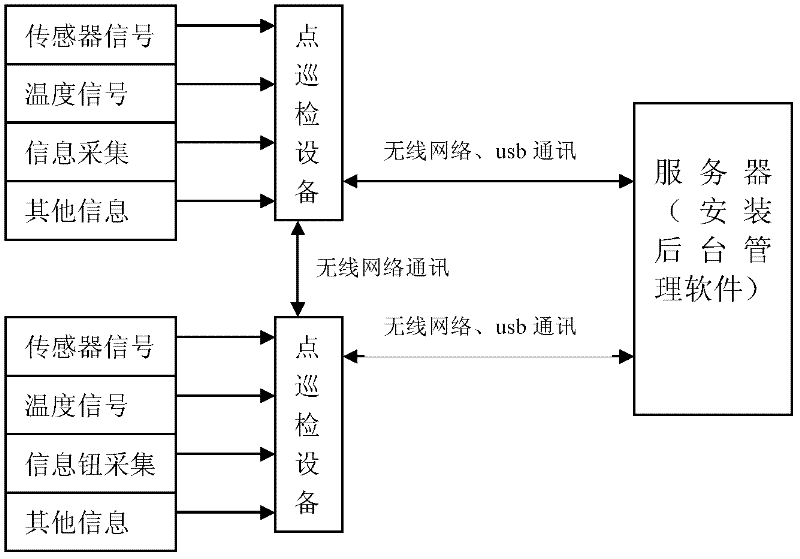

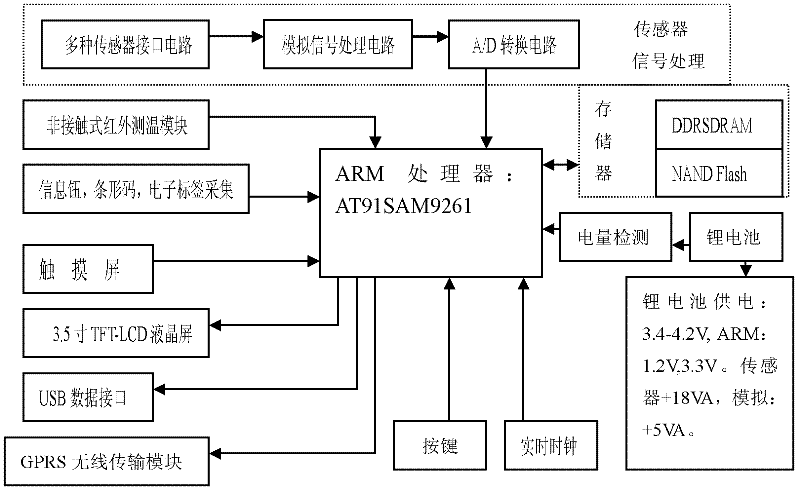

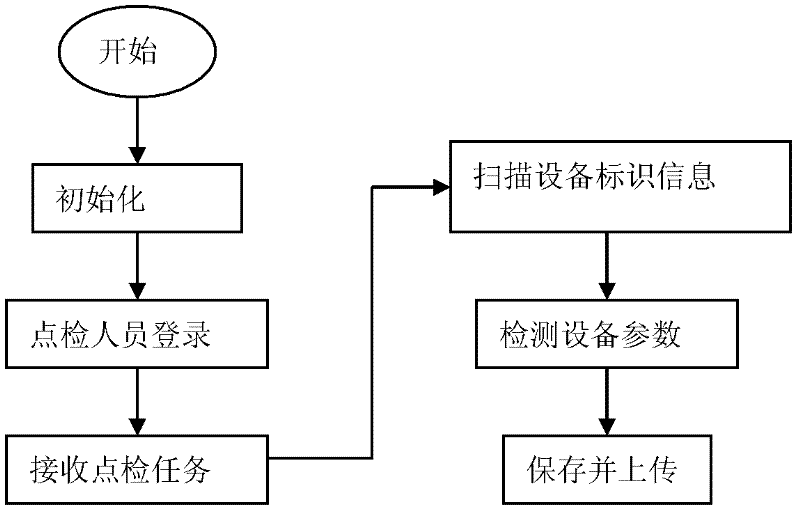

[0037] The intelligent point inspection and fixed repair instrument of the present invention needs background management software to transmit the formulated inspection plan to the new type intelligent point inspection equipment, and the operator logs in to the new type intelligent point inspection equipment, and first obtains the measured equipment according to the inspection plan Then through different sensors and the modules that come with the new smart point inspection equipment, the vibration acceleration, speed, displacement, temperature and other parameters of the equipment can be detected, and the new smart point inspection can also be input according to the parameters and phenomena observed on site. In the inspection equipment, the new intelligent point inspection equipment will save the data, analyze and diagnose the data, and can also transmit the data to the background management software in real time for further analysis and diagnosis.

[0038] The new intelligent p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com