Speed simulation type cable drum

A cable reel and speed imitation technology, which is applied in the field of mobile equipment cable reels, can solve the problems of shortened cable service life, large drop in cable pre-tightening force, wear and tear of cable reel coupling devices, etc., to reduce equipment costs and meet Simultaneous requirements, easy maintenance and intuitive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

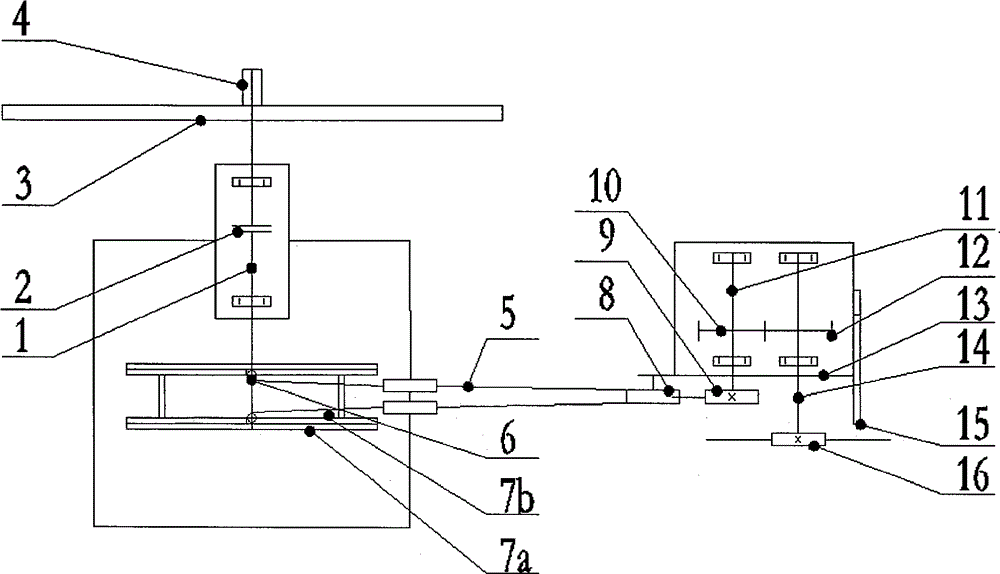

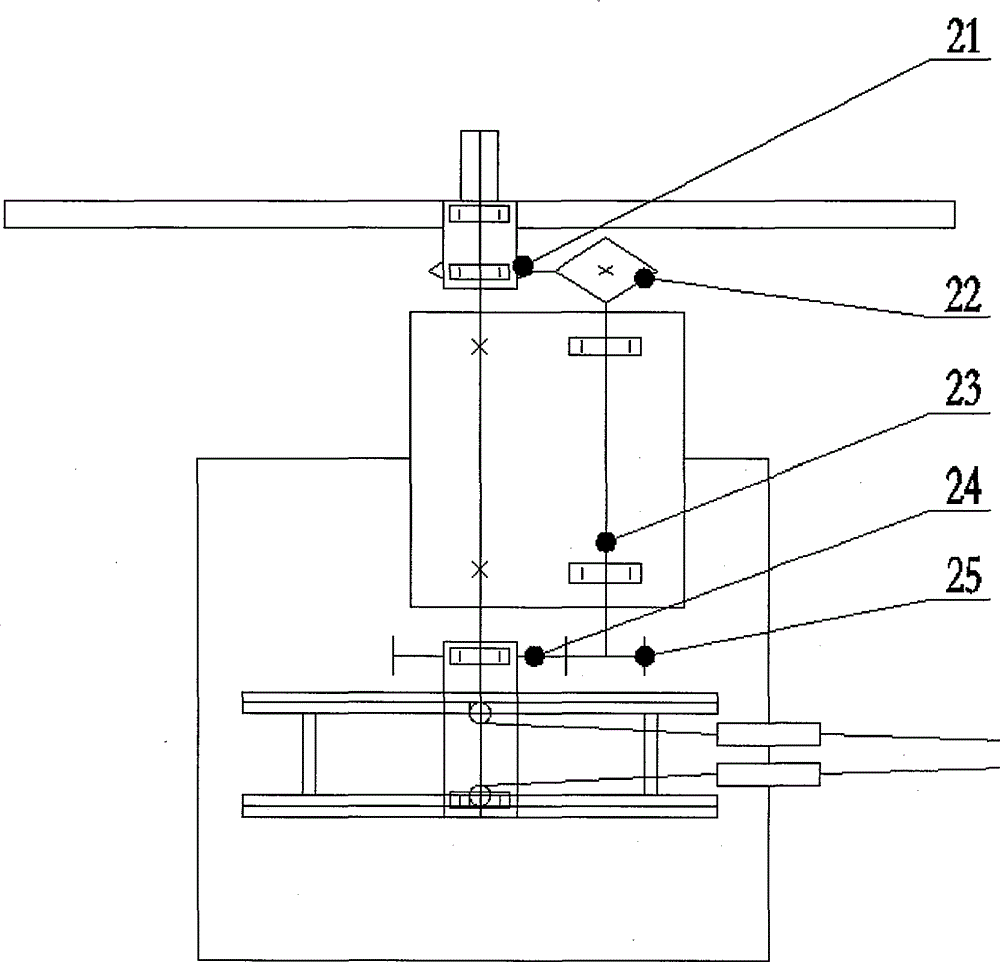

[0031] The speed-following type cable reel of the present invention is described in further detail below in conjunction with the accompanying drawings:

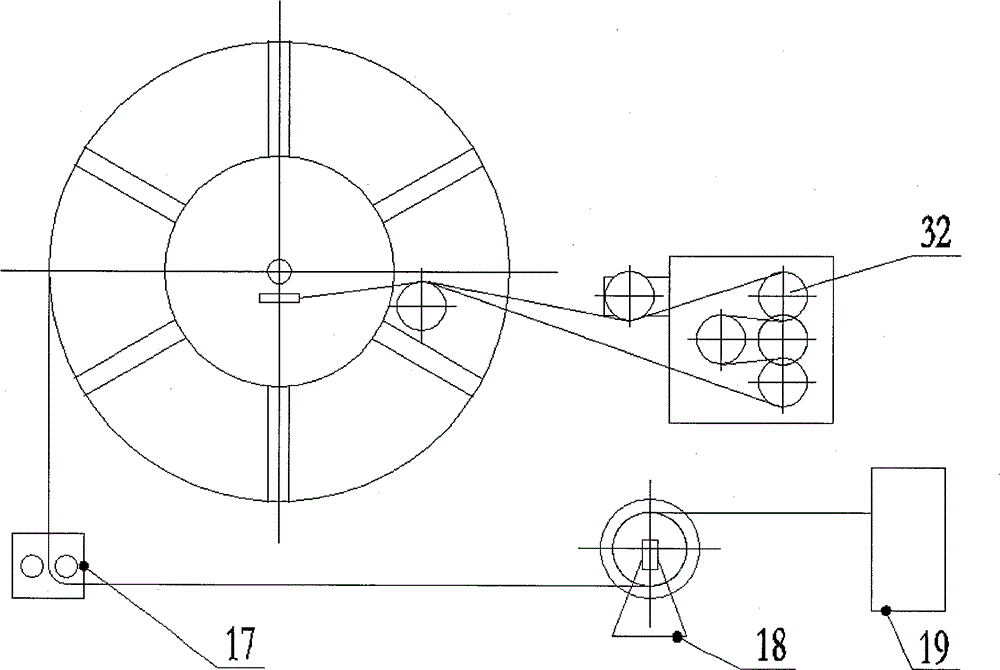

[0032] The speed-imitating cable reel 3 is composed of the wheel output shaft 14 and the sun gear 12 on it, the wire wheel assembly 32, the reversing wheel assembly 33, the tensioning wheel 8 components, the wire pulley 6 components, and the double-connected speed-imitating reel assembly 7 components. , reel connector 2, cable reel 3 components, collector 4, fairlead 17) and synchronous error regulator 18.

[0033] A wheel output shaft 14, three satellite gear shafts 11, a reversing wheel shaft 30 are installed in the gear box 13 holes, a sun gear 12, a sprocket 1, 26 and two electromagnetic clutches are installed on the wheel output shaft 14 28; 29, an electromagnetic clutch 29 controls the sun gear 12, and an electromagnetic clutch 28 controls the sprockets 1, 26. Three satellite gear shafts 11 are installed on the gear bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com