Scaling-free microwave photocatalytic reactor applied to industrial wastewater degradation processing

A technology of industrial wastewater degradation and catalytic reaction, which is applied in the direction of light water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of blocking the ultraviolet radiation of the electrodeless ultraviolet lamp and reducing the treatment efficiency of the microwave photocatalytic reaction treatment device, etc. Achieve high permeability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

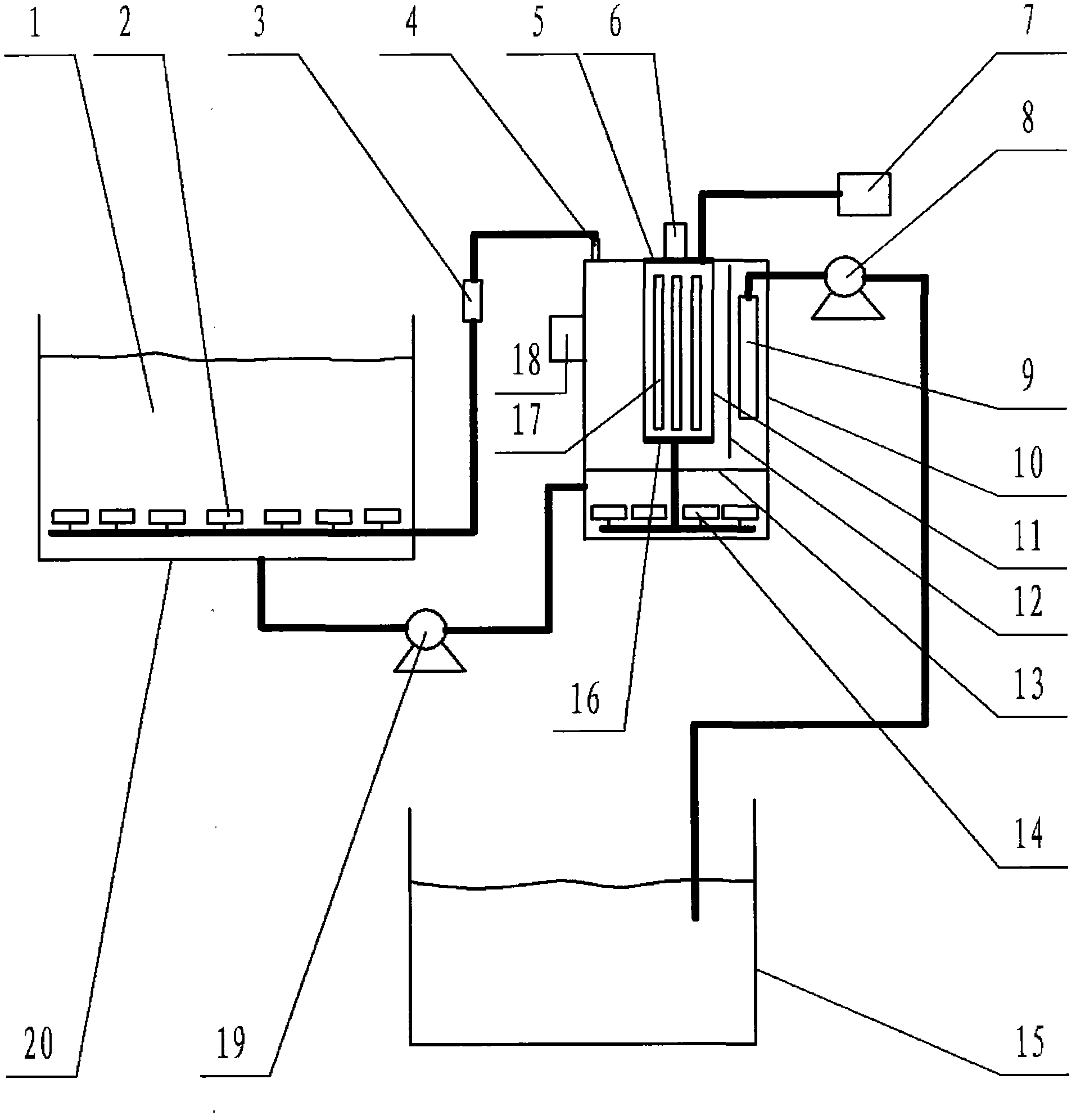

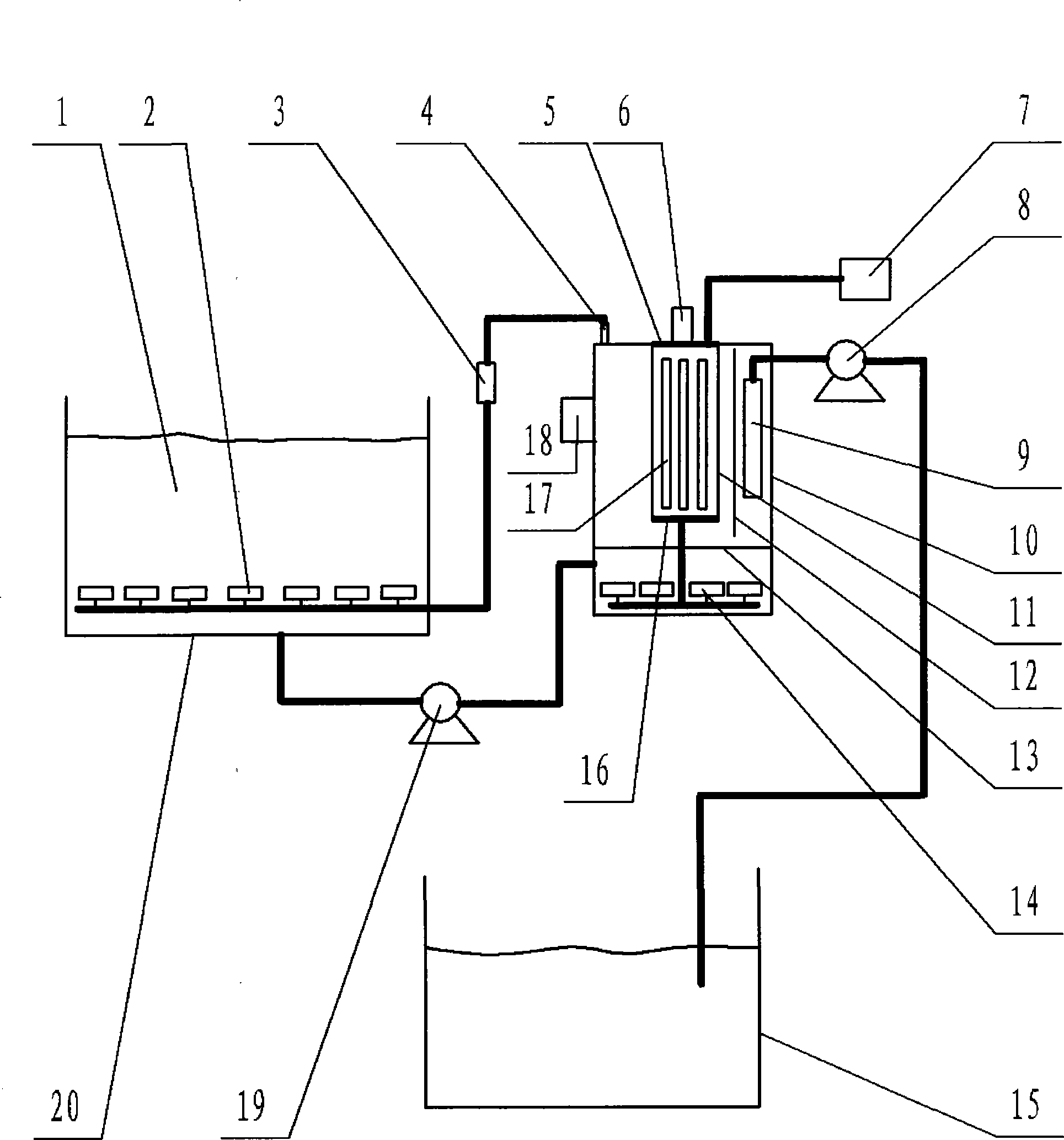

[0030] exist figure 1 In the shown embodiment of the present case, the structure of the device includes a reactor 10 whose outline is in the shape of a square barrel or a drum, and a water distribution plate 13 that contains many holes plate, the water distribution plate 13 divides the interior space of the reactor 10 into a microwave photocatalytic reaction chamber at the upper part and an aeration chamber at the lower part, and some microporous aeration heads 14 are installed in the aeration chamber, and , quartz tube 11, the erection position of this quartz tube 11 is the inside of the microwave photocatalytic reaction chamber, the two ends of this quartz tube 11 are equipped with sealing caps 5,16, and the sealing caps located at the two ends of the quartz tube are respectively All offer the interface that is used to connect trachea on the capping head 5,16, and, electrodeless ultraviolet lamp 17, this electrodeless ultraviolet lamp 17 also can be rod-shaped, and this elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com