Active synergist for concrete and cement products

A technology for cement products and synergists, applied in the directions of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of high cost of high-pressure equipment, long cycle, and finished products meet design requirements, so as to improve production efficiency , huge economic and social benefits, the effect of shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A high-performance active synergist, which is uniformly compounded by various components. The proportions of each component by weight percentage are: 10% microsilica, 70% natural ground gypsum, 14% highly active calcium oxide, 1% N-acyl lauryl sarcosinate, 5% % silicate. The following performance tests were carried out for the compounded high activity synergist and its application.

[0015] 1. Experiments on improving the fluidity of cement paste and the strength of mortar by using active synergists

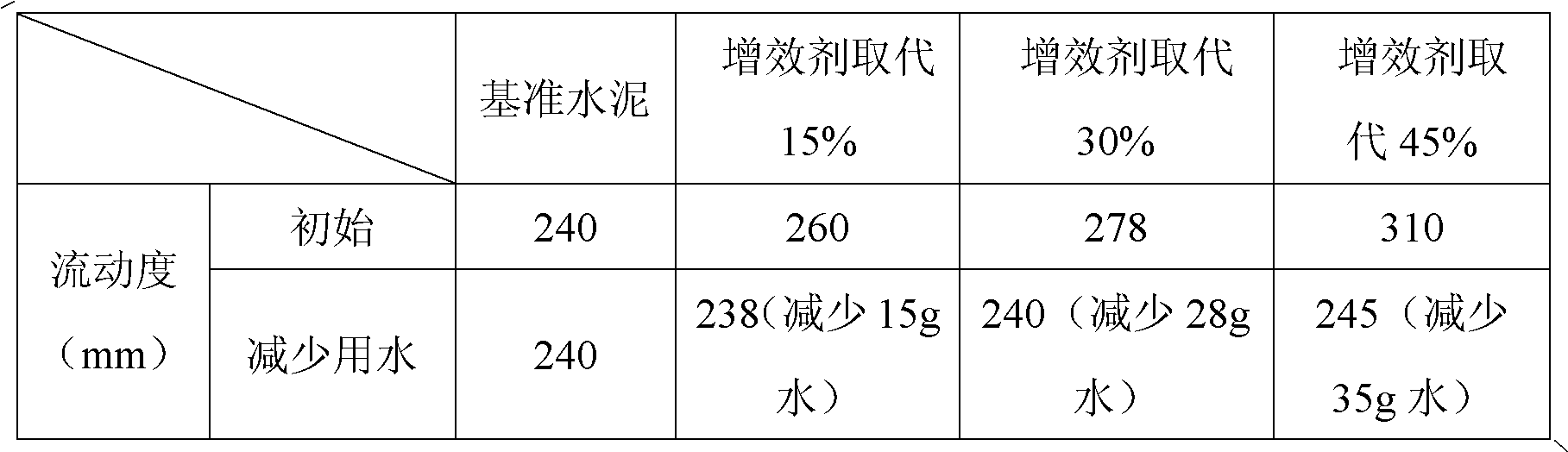

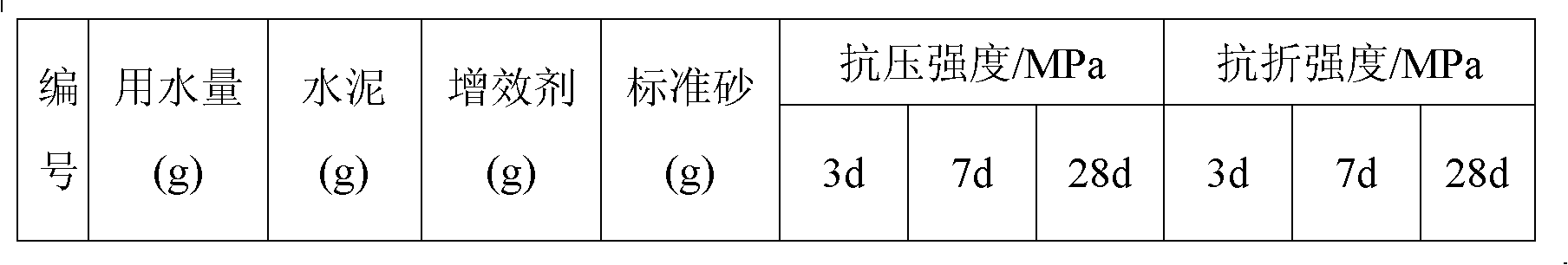

[0016] In 500g of P·II52.5 grade cement, add 150g of water and 7.5g of naphthalene-based water reducer to obtain a benchmark cement slurry with a water-binder ratio of 0.30; then use the cement in the benchmark cement slurry with an active The synergists replaced 15%, 30% and 45% by weight to obtain four cement slurries, and the four cement slurries were tested. Table 1 shows the flow properties of four kinds of cement slurries.

[0017] Table 1

[0018]

[0019] I...

Embodiment 2

[0039] A high-performance active synergist, which is uniformly compounded by various components. The ratio of each component by weight percentage is: 50% superfine fly ash, 10% natural ground gypsum, 20% desulfurized gypsum, 15% highly active calcium oxide, 1% N lauroyl glycine Potassium, 4% inorganics. The following performance tests were carried out for the compounded high activity synergist and its application.

[0040] 1. Experiments on improving the fluidity of cement paste and the strength of mortar by using active synergists

[0041] In 500g of P·II52.5 grade cement, add 150g of water and 7.5g of naphthalene-based water reducer to obtain a benchmark cement slurry with a water-binder ratio of 0.30; then use the cement in the benchmark cement slurry with an active The synergists replaced 15%, 30% and 45% by weight to obtain four cement slurries, and the four cement slurries were tested. Table 1 shows the flow properties of four kinds of cement slurries. Table 1

[00...

Embodiment 3

[0062] A high-performance active synergist, which is uniformly compounded by various components. The proportions of each component by weight percentage are: 10% microsilica, 18% ultrafine fly ash, 10% desulfurized gypsum, 60% highly active calcium oxide, 0.5% N-lauroyl glutamic acid Sodium acid, 1.5% inorganic substances. The following performance tests were carried out for the compounded high activity synergist and its application.

[0063] 1. Experiments on improving the fluidity of cement paste and the strength of mortar by using active synergists

[0064] In 500g of P·II52.5 grade cement, add 150g of water and 7.5g of naphthalene-based water reducer to obtain a benchmark cement slurry with a water-binder ratio of 0.30; then use the cement in the benchmark cement slurry with an active The synergists replaced 15%, 30% and 45% by weight to obtain four cement slurries, and the four cement slurries were tested. Table 1 shows the flow properties of four kinds of cement slurri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com