Method and device for purifying 2,4-dichlorophenol

A technology of dichlorophenol and purification method, which is applied in the field of preparation of pesticide chemical intermediates, and can solve problems such as environmental pollution, waste gas pollution, and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

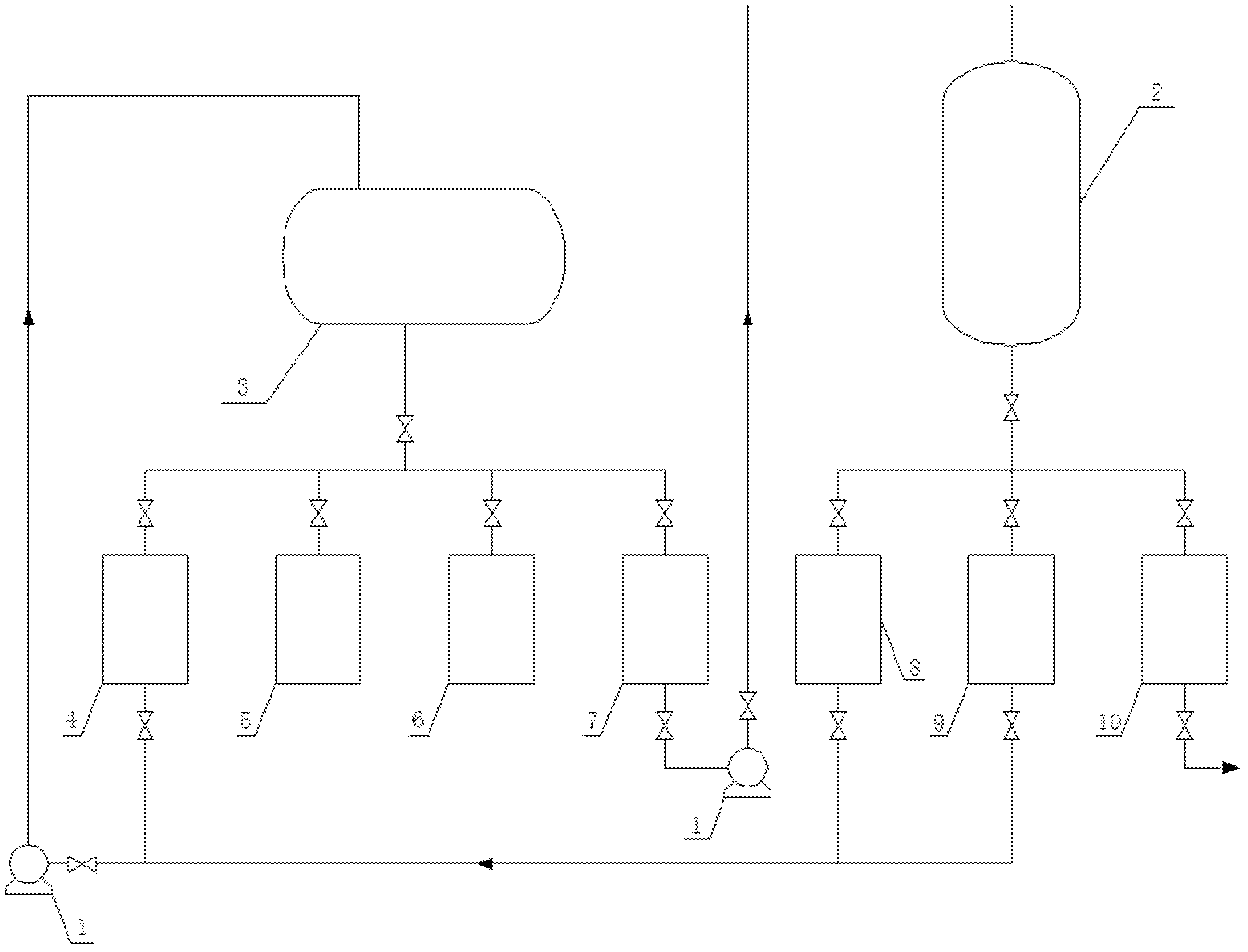

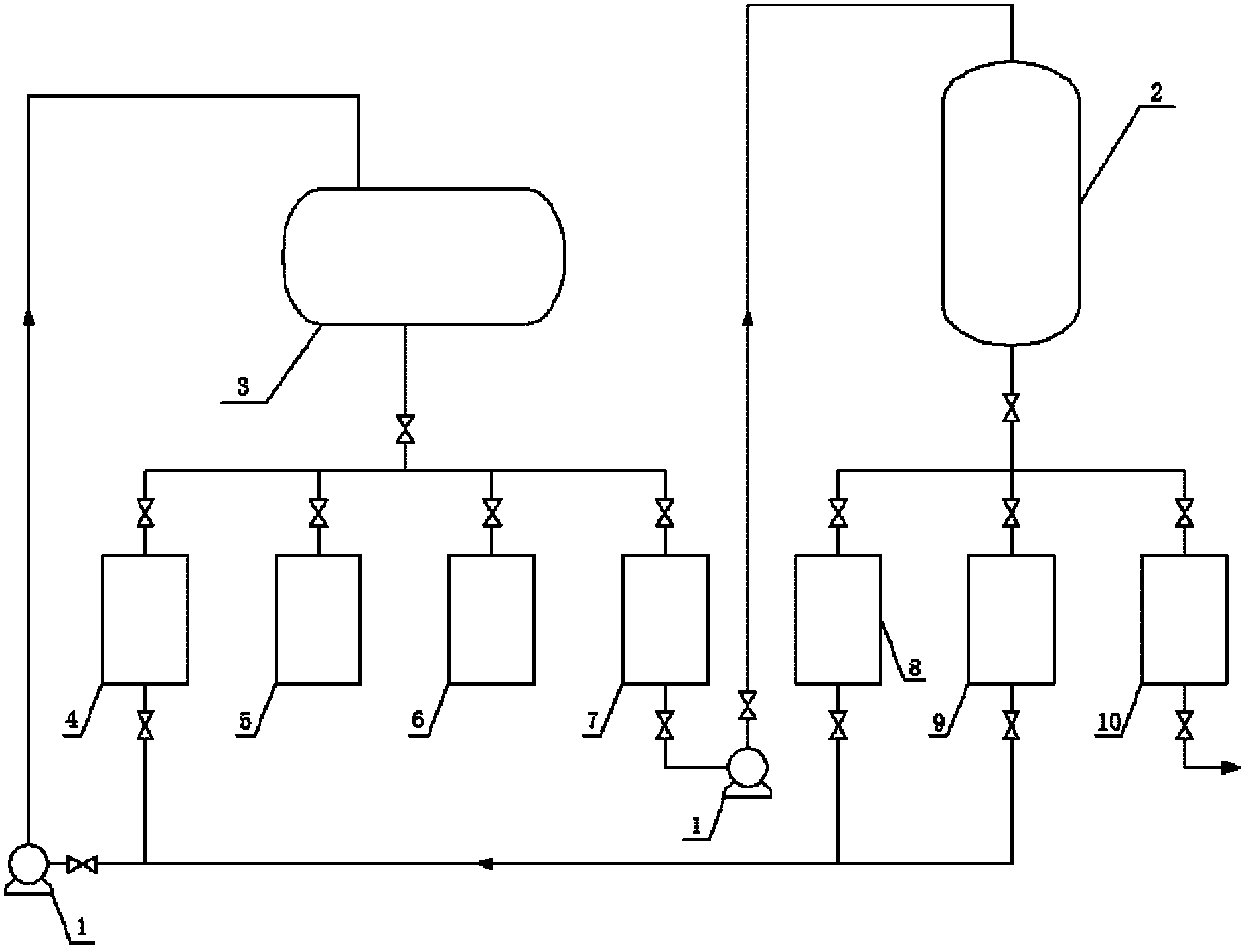

Image

Examples

Embodiment 1

[0019] Import the crude product of 2,4-dichlorophenol from the material pump 1 into the crystallizer 3, lower the temperature to crystallize, pay attention to observe the material condition in the crystallizer, when crystals are precipitated, continue to cool down slowly to make the crystal layer grow. The cooling rate is 0.015°C / min. After cooling down to 10°C, discharge the uncrystallized mother liquor into the mother liquor tank 4, raise the temperature at a rate of 0.06°C / min to make the crystal layer sweat, the end point temperature of sweating is 30°C, discharge the sweat into the sweat tank 7, raise the temperature to make the crystal layer Melting, collecting the molten liquid in the finished product tank 5 of 2,4-dichlorophenol and taking samples for analysis. Collect 2,6-dichlorophenol crystals into 2,6-dichlorophenol finished product tank 6. The purity of the obtained 2,4-dichlorophenol is 99.23%, and the product yield is 99.13% after calculation. The mother liquo...

Embodiment 2

[0021] Import the crude product of 2,4-dichlorophenol into the crystallizer, lower the temperature to crystallize, pay attention to observe the material condition in the crystallizer, when crystals are precipitated, continue to cool down slowly to make the crystal layer grow. The cooling rate is 0.020 / min. After cooling down to 15°C, discharge the uncrystallized mother liquor, raise the temperature at a rate of 0.07°C / min to make the crystal layer sweat, the end point temperature of sweating is 40°C, discharge the sweat, raise the temperature to melt the crystal layer, collect the molten liquid and take samples for analysis. The purity of the obtained 2,4-dichlorophenol is 99.07%, and the product yield is 99.22% after calculation. After collecting the uncrystallized sweat, pump it into the rectification tower kettle, evacuate it, and control the vacuum at 30mmHg, heat the mixed solution to 170°C, and carry out vacuum distillation. Phenol, monochlorophenol, 2,4-dichlorophenol ...

Embodiment 3

[0023] Import the crude product of 2,4-dichlorophenol into the crystallizer, lower the temperature to crystallize, pay attention to observe the material condition in the crystallizer, when crystals are precipitated, continue to cool down slowly to make the crystal layer grow. The cooling rate is 0.035°C / min. After cooling down to 20°C, discharge the uncrystallized mother liquor, raise the temperature at a rate of 0.08°C / min to make the crystal layer sweat, the end point temperature of sweating is 50°C, discharge the sweat, raise the temperature to melt the crystal layer, collect the molten liquid and take samples for analysis. The purity of 2,4-dichlorophenol obtained is 98.84%, and the product yield is 94.63% after calculation. After collecting the uncrystallized sweat, pump it into the rectification tower kettle, evacuate it, control the vacuum at 40mmHg, heat the mixed solution to 180°C, and carry out vacuum distillation. Phenol, monochlorophenol, 2,4-dichlorophenol crude ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com