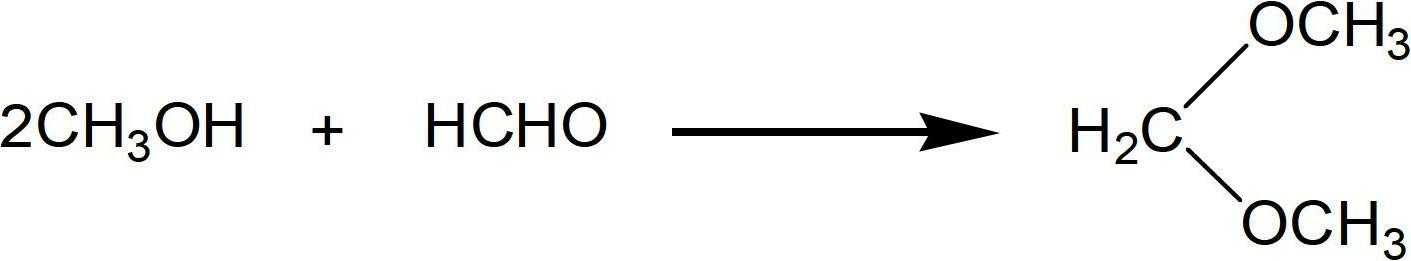

Synthesis technology for preparing methylal by virtue of condensation of methyl alcohol and formaldehyde

A synthesis process and formaldehyde condensation technology, applied in the field of catalysis, can solve the problems of low methylal yield, unfavorable energy saving and emission reduction transformation, etc., and achieve the effects of high yield, low cost, and improved synthesis yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will now be described in further detail.

[0016] A kind of synthesis technique concrete step of methylal of the present invention is produced by condensation of methanol and formaldehyde is as follows:

[0017] First, add 80g of methanol to a 250ml four-neck flask equipped with a condenser, and then add 45g of formalin; among them, the function of the condenser is to condense the gas discharged during the reaction of methanol and formaldehyde into a liquid through heat dissipation.

[0018] Secondly, in order to further improve the reaction rate, in the mixed solution of methanol and formalin, add the freshly prepared iron-based solid superacid catalyst of 3g;

[0019] Again, under normal pressure, pass the mixed solution through a constant temperature water bath. The temperature of the constant temperature water bath ranges from 39°C to 43°C, and the optimum temperature is 41.8°C. At this temperature, the yield of formaldehyde can reach 100%. . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com