Yellow long afterglow light-emitting material and preparing method thereof

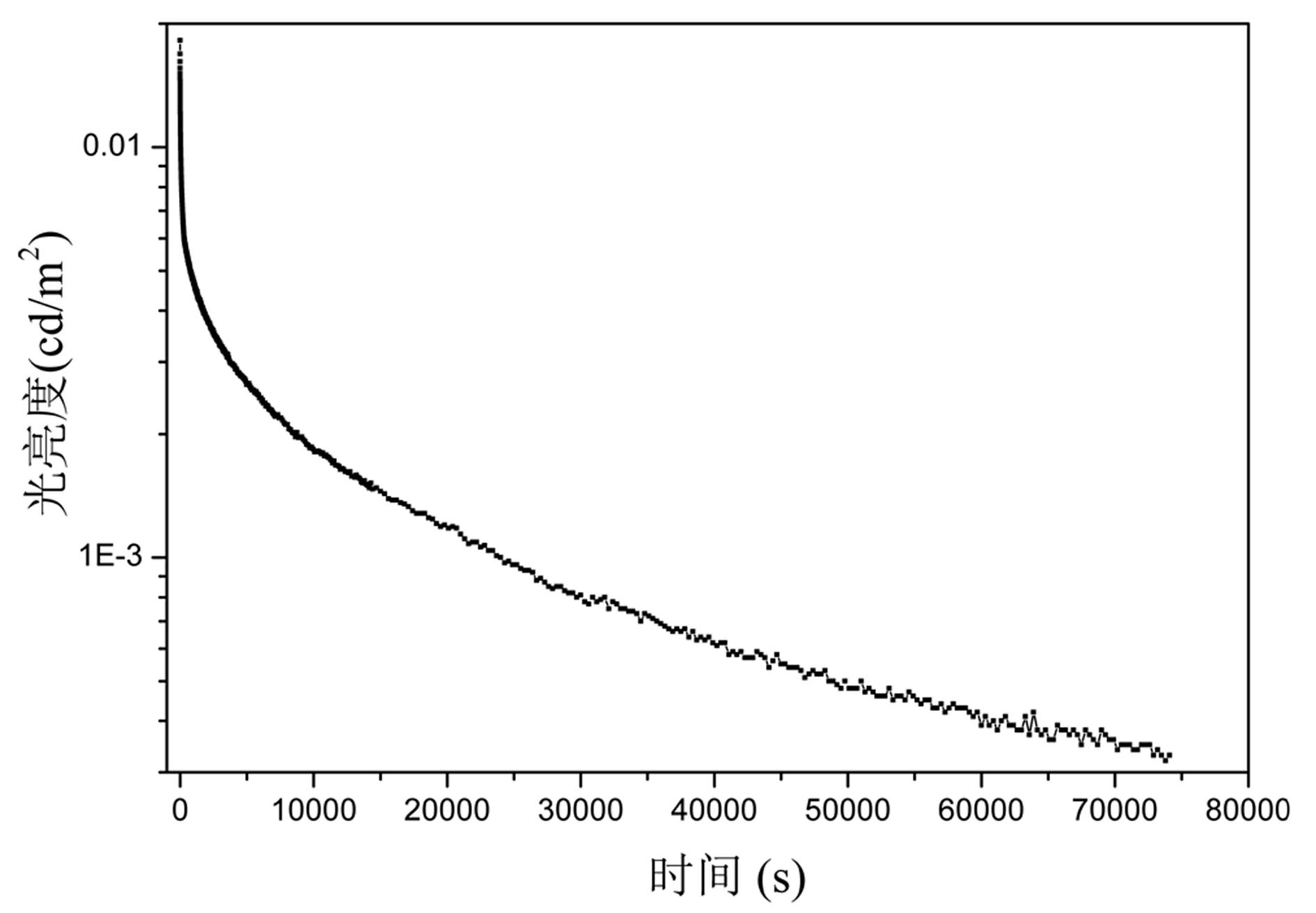

A technology of long afterglow luminescence and long afterglow materials, which is applied in the direction of luminescent materials, chemical instruments and methods, etc. It can solve the problems of unpublished afterglow time, initial brightness of afterglow, difficult materials, waste of energy, etc., and achieve long afterglow duration and excellent preparation method Simple, good color purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] According to Ca 1.98 BO 3 Cl: Eu 0.01 , Dy 0.01 The molecular formula weighs 1.4813gCaCO respectively 3 , 0.5549gCaCl 2 , 0.6183gH 3 BO 3 , 0.0176gEu 2 o 3 and 0.0186gDy 2 o 3 Add appropriate amount of alcohol to the weighed raw material and grind it in a mortar, mix it evenly, put it into an alumina crucible, put it in a tube furnace, and bake it for 4 hours at a temperature of 900 ° C and a reducing atmosphere. , the reducing atmosphere used is composed of 5%H by volume percentage 2 and 95%N 2 composition. After the calcination is completed, it is cooled to room temperature with the furnace, and the long afterglow material is obtained after grinding.

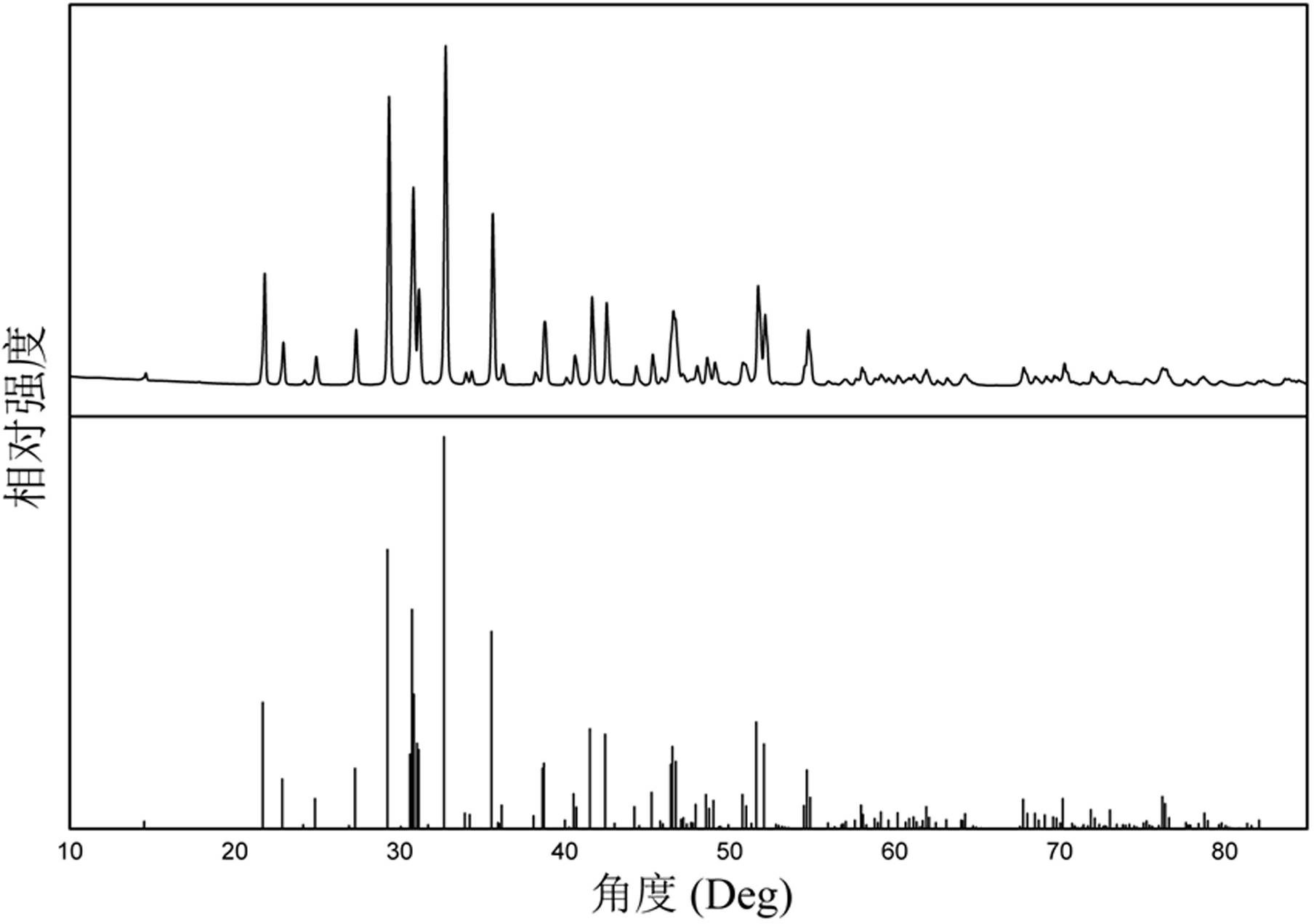

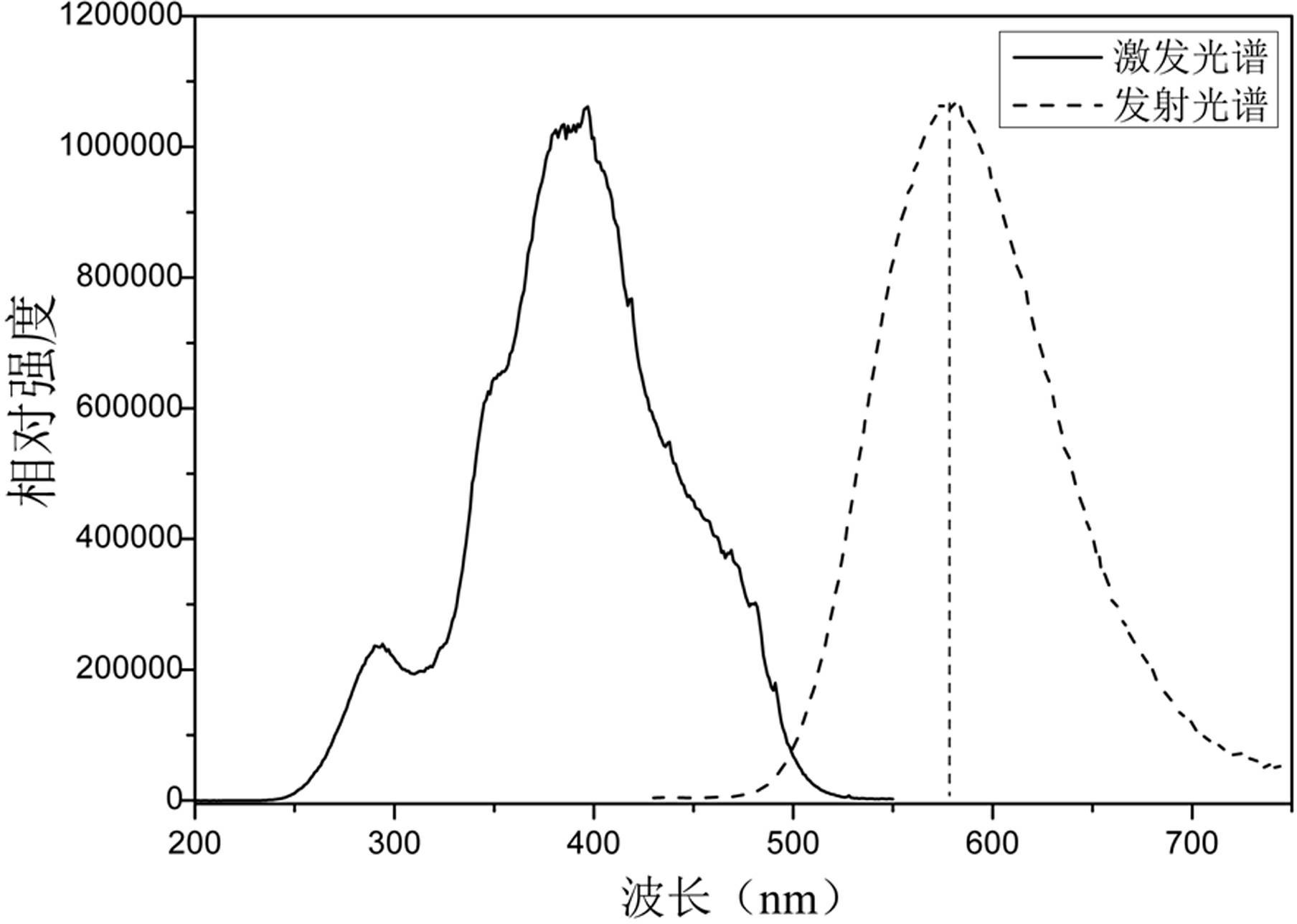

[0043] The X-ray diffraction pattern of the obtained long afterglow material is as follows: figure 1 It can be seen from the figure that the diffraction peaks of the sample are in good agreement with the PDF standard card. Illustrate that adopting the sample that the inventive method makes is all Ca 2 BO...

Embodiment 2

[0047] According to Ca 1.998 BO 3 Cl: Eu 0.001 , Dy 0.001 The molecular formula weighs 1.4993gCaCO respectively 3 , 0.6103gCaCl 2 , 0.3829gB 2 o 3 , 0.0018gEu 2 o 3 and 0.0017 g CeO 2 , where CaCl 2 and B 2 o 3 An excess of 10% is used to compensate for the volatilization during the calcination process. Add an appropriate amount of alcohol dropwise to the weighed raw materials and grind them in a mortar. After mixing evenly, put them into an alumina crucible and place them in a tube furnace. and roasting for 1 hour under the condition of introducing a reducing atmosphere, in the presence of 25%H 2 and 75%N 2 Insulated under the reducing atmosphere for 1h, the reducing atmosphere used was changed from 25%H 2 and 75%N 2 After the calcination is completed, it is cooled to room temperature with the furnace, and the yellow long afterglow material is obtained after grinding.

Embodiment 3

[0049] According to Ca 1.96 BO 3 Cl: Eu 0.02 , Nd 0.01 , Tm 0.01 Weigh 0.3979gCaO, 0.3608gCaCl respectively 2 , 0.3413gH 3 BO 3 , 0.0352gEu 2 o 3 , 0.0168gNd 2 o 3 and 0.0193gTm 2 o 3 , where CaCl 2 Excess 30%, H 3 BO 3 An excess of 20% is used to compensate for the volatilization during the calcination process. Add an appropriate amount of alcohol to the weighed raw material and grind it in a mortar. Under the condition of roasting for 2.5 hours, the reducing atmosphere used was 5% CO and 95% N by volume. 2 After the calcination is completed, it is cooled to room temperature with the furnace, and the yellow long afterglow material is obtained after grinding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com