Preparation method of rare earth doped nano zirconia up-conversion phosphor powder

A nano-zirconia and rare earth doping technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of concentration quenching, reduction of fluorescence emission intensity, interaction enhancement, etc., and achieve simple preparation process and high fluorescence efficiency of finished products , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

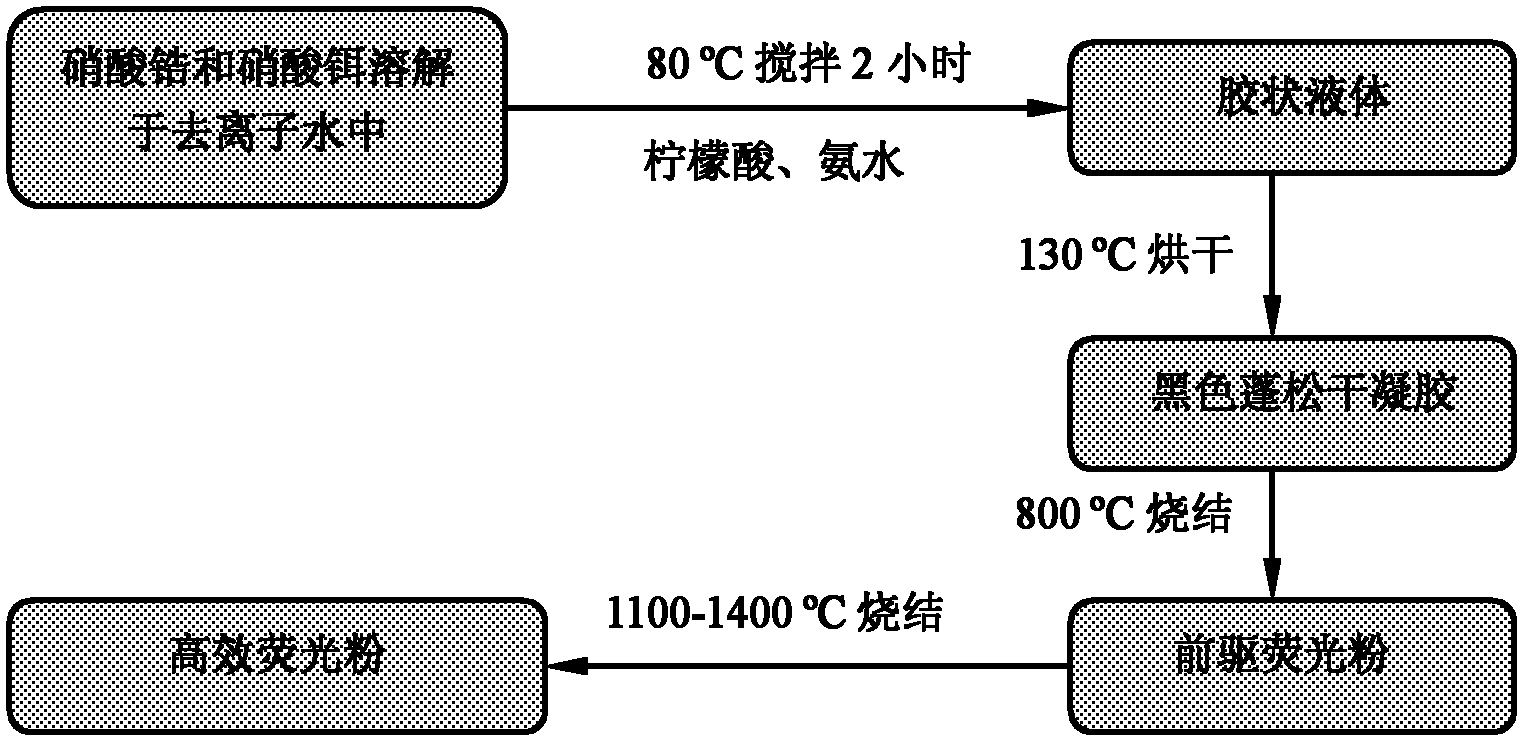

Method used

Image

Examples

Embodiment approach 1

[0017] Embodiment 1: according to formula ratio (molar ratio):

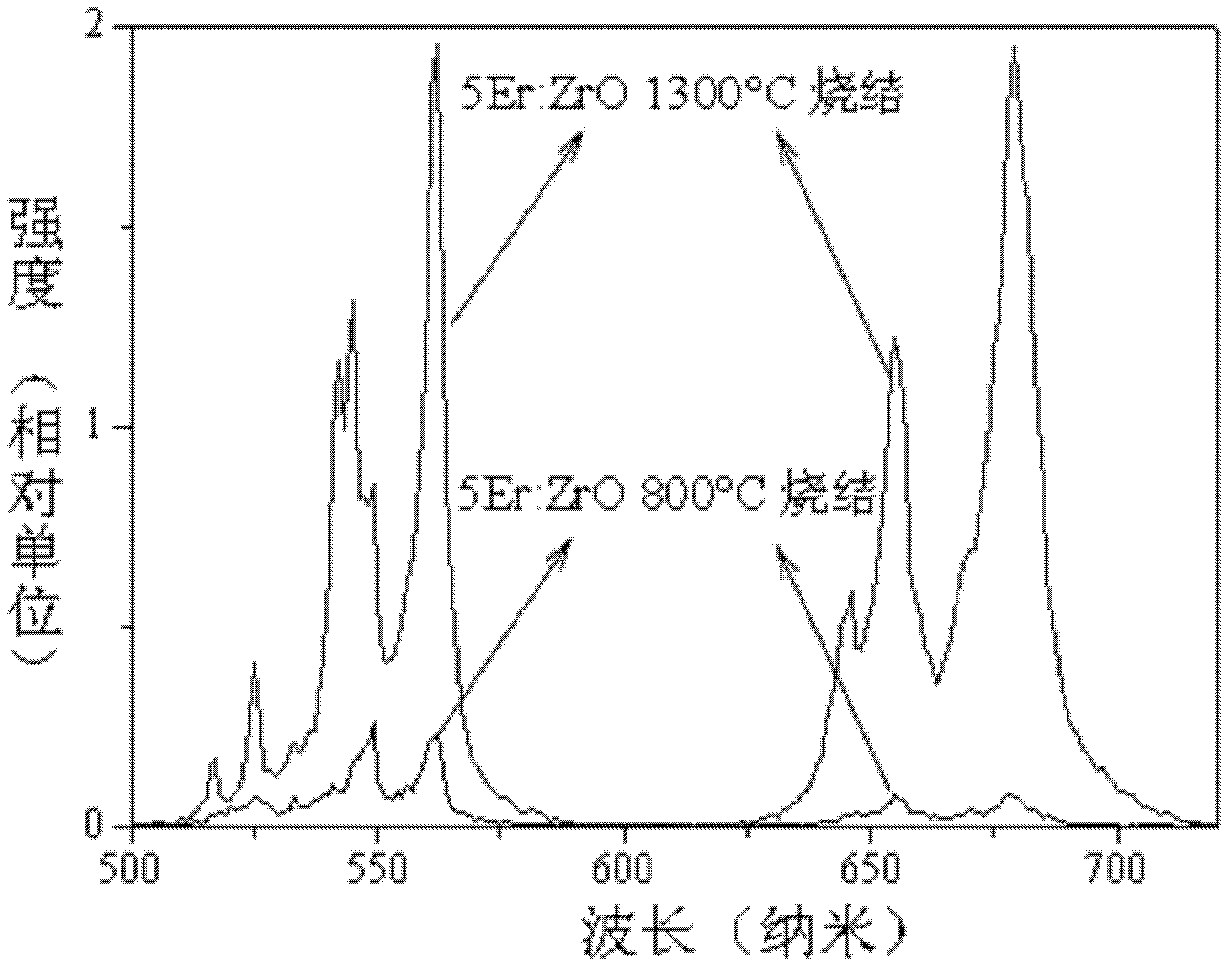

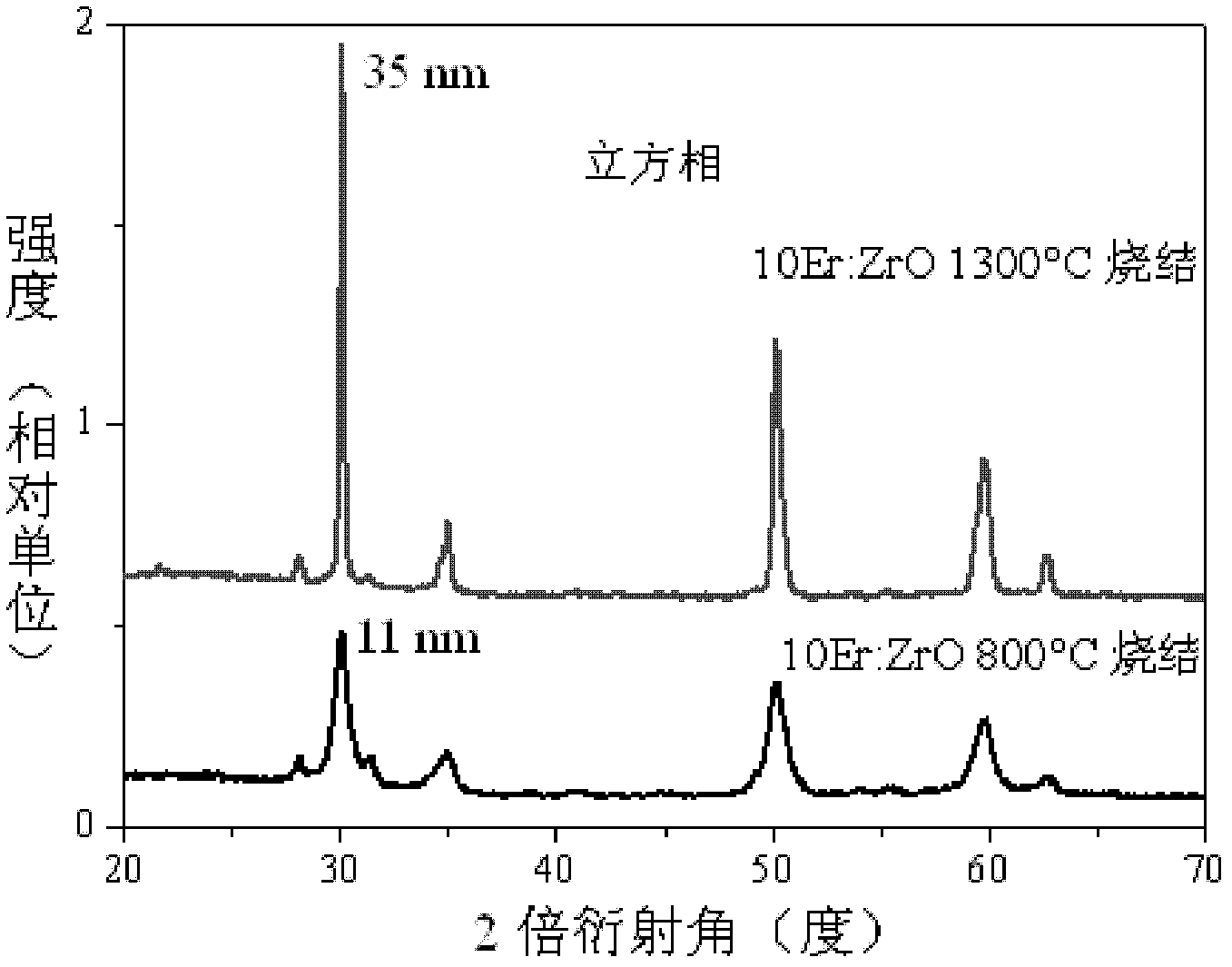

[0018] 0.05Er(NO 3 ) 3 : 1Zr(NO 3 ) 4 The xerogel of the synthesized sample was sintered at 800 degrees Celsius for 2 hours to obtain the precursor phosphor, and then calcined for a second time at 1100 degrees Celsius for 2 hours.

[0019] The basic formula remains unchanged, only Er(NO 3 ) 3 The proportion that accounts for, obtains following several different implementation modes:

Embodiment approach 2

[0020] Embodiment 2: according to formula ratio 0.1Er (NO 3 ) 3 : 1Zr(NO 3 ) 4 Preparation of xerogel, the following is the same as Embodiment 1.

Embodiment approach 3

[0021] Embodiment 3: according to formula ratio 0.15Er(NO 3 ) 3 : 1Zr(NO 3 ) 4 Preparation of xerogel, the following is the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com