Magnetic suspension damping device

A shock absorbing device and magnetic levitation technology, applied in the direction of spring/shock absorber, magnetic spring, spring, etc., can solve the problems of poor high-frequency vibration isolation effect, inability to adapt to low temperature, complicated inflatable process, etc., and achieve low sealing requirements, Long service life and small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described below in combination with specific embodiments and with reference to the accompanying drawings.

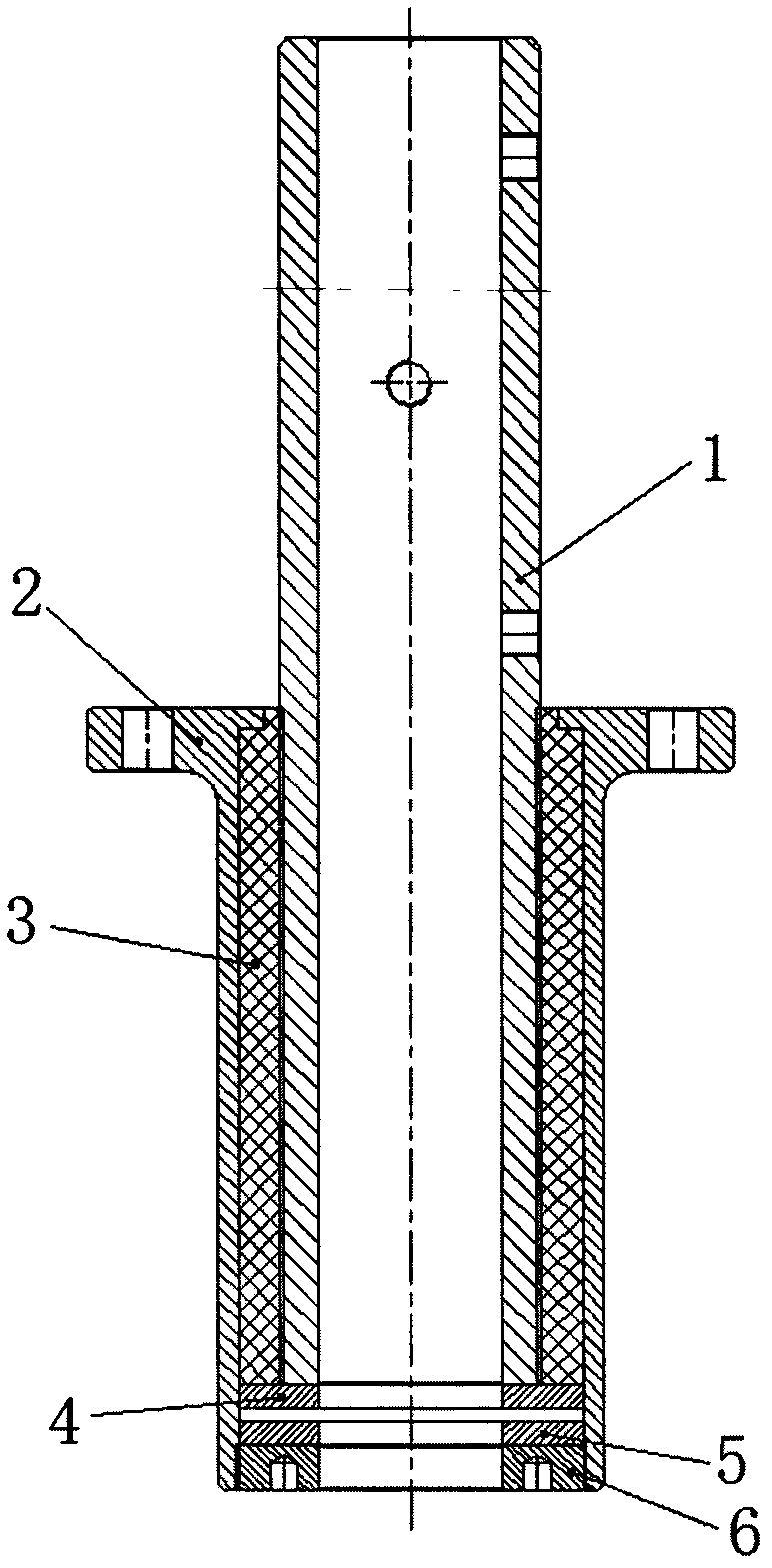

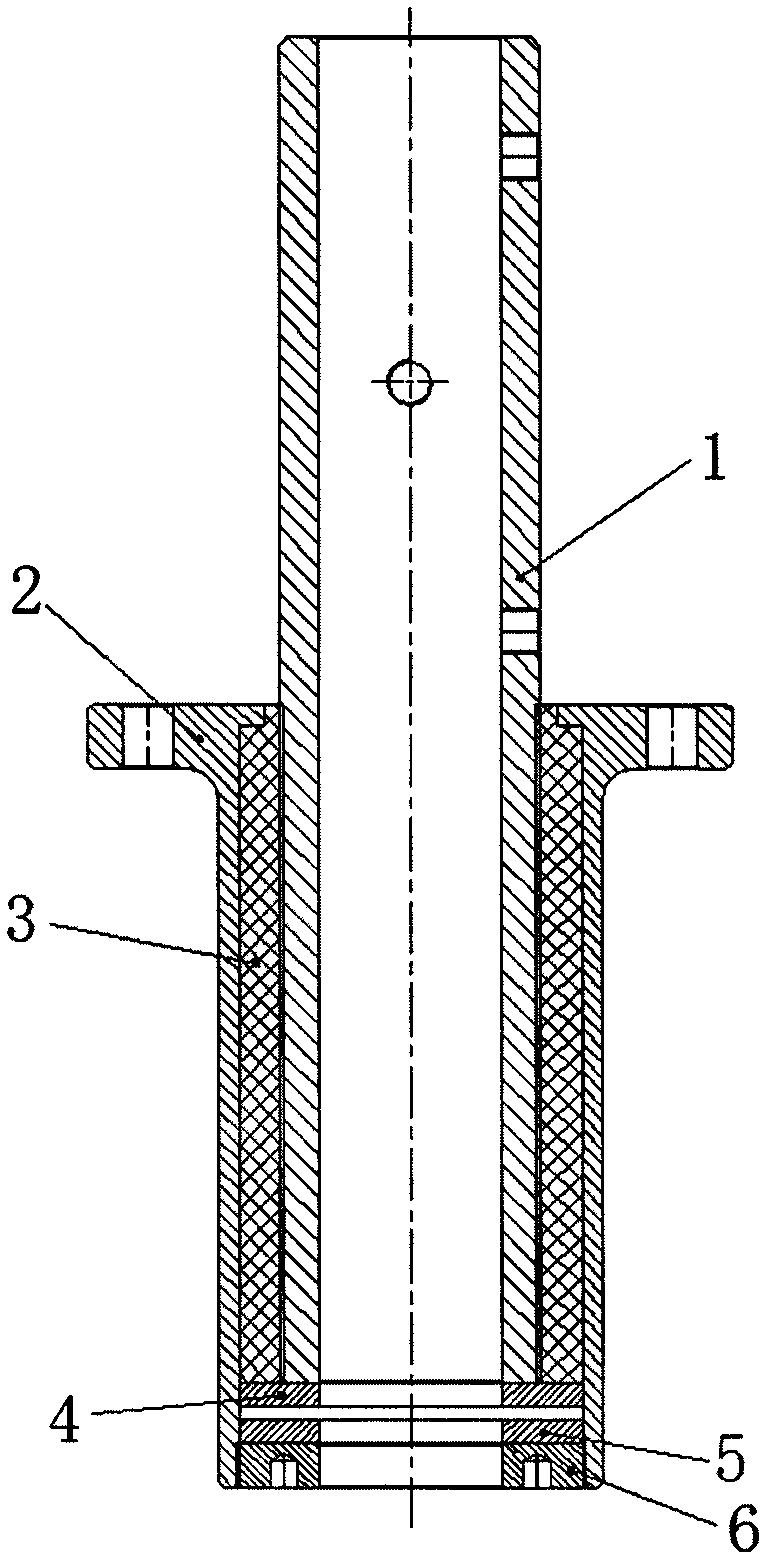

[0022] A magnetic levitation shock absorber used in a high-speed rotating vertical axis maglev wind power generator as shown in the accompanying drawing, including a hollow piston rod 1 made of aluminum alloy, a guide sleeve 3 made of rubber, and a cylinder barrel 2 , the guide sleeve 3 and the hollow piston rod 1 cooperate with each other through threads, the bottom end face of the guide sleeve 3 is aligned with the bottom end face of the hollow piston rod 1, the guide sleeve 3 is used for guiding the hollow piston rod 1, and the radial direction of the hollow piston rod 1 is relieved. Due to the vibration generated by the swing, the outer surface of the guide sleeve 3 and the inner surface of the cylinder 2 are in clearance fit, and the hollow piston rod 1 drives the guide sleeve 3 to move back and forth in the cylinder 2 stably.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com