Light-emitting diode (LED) light engine module

An LED module and light engine technology, applied in the field of lighting, can solve the problems of difficult maintenance in the later stage, fragile dust-proof glass cover, and unsatisfactory heat dissipation effect, so as to solve the complex production process and the difficulty of later maintenance, reduce light The effect of preventing loss, easy and quick repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

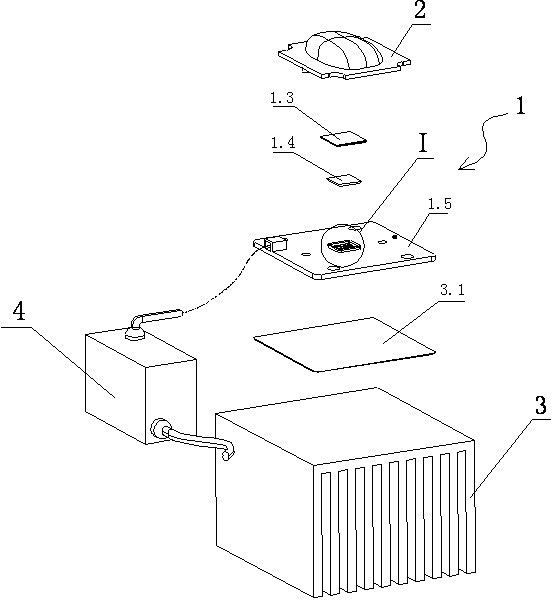

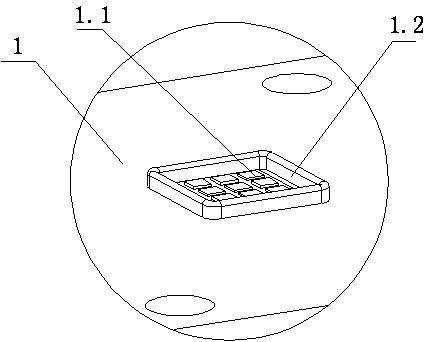

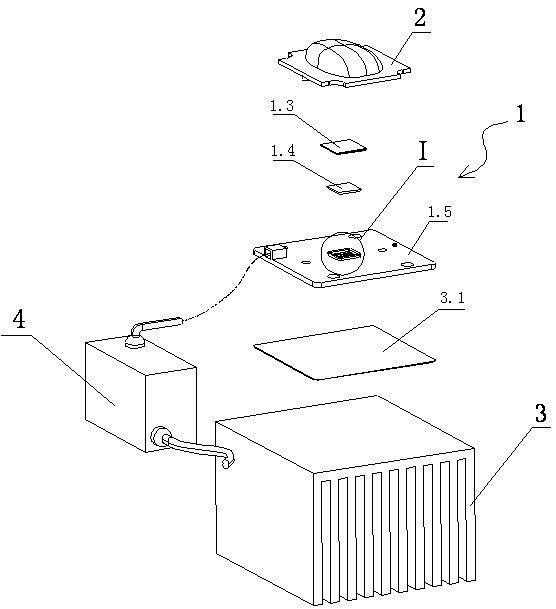

[0024] see figure 1 with figure 2 , a kind of LED light engine module that the present invention relates to, said module includes LED module light source 1, secondary optical lens 2, radiator 3 and power supply 4, and said LED module light source 1 includes substrate 1.5 (the substrate 1.5 is a metal substrate MCPCB or a ceramic substrate), on which a plurality of LED chips 1.1 are welded (the LED chips 1.1 are flip-chip installed on the substrate 1.5), and a dam 1.2 is also arranged on the substrate 1.5, so The LED chips 1.1 are located in the middle of the dam 1.2, the secondary optical lens 2 is covered on the LED chip 1.1, and a silica gel layer 1.3 and a phosphor layer are arranged between the secondary optical lens 2 and the LED chip 1.1 1.4, the phosphor layer 1.4 covers the LED chip 1.1, the silica gel layer 1.3 covers the phosphor layer 1.4; the substrate 1.5 of the LED module light source 1 is fixed on the top of the heat sink 3, and the LED module A silicone gask...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com