Porous film and electricity storage device

A technology of porous membrane and power storage device, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of poor battery heating safety, and achieve excellent battery characteristics, processability, and excellent liquid absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

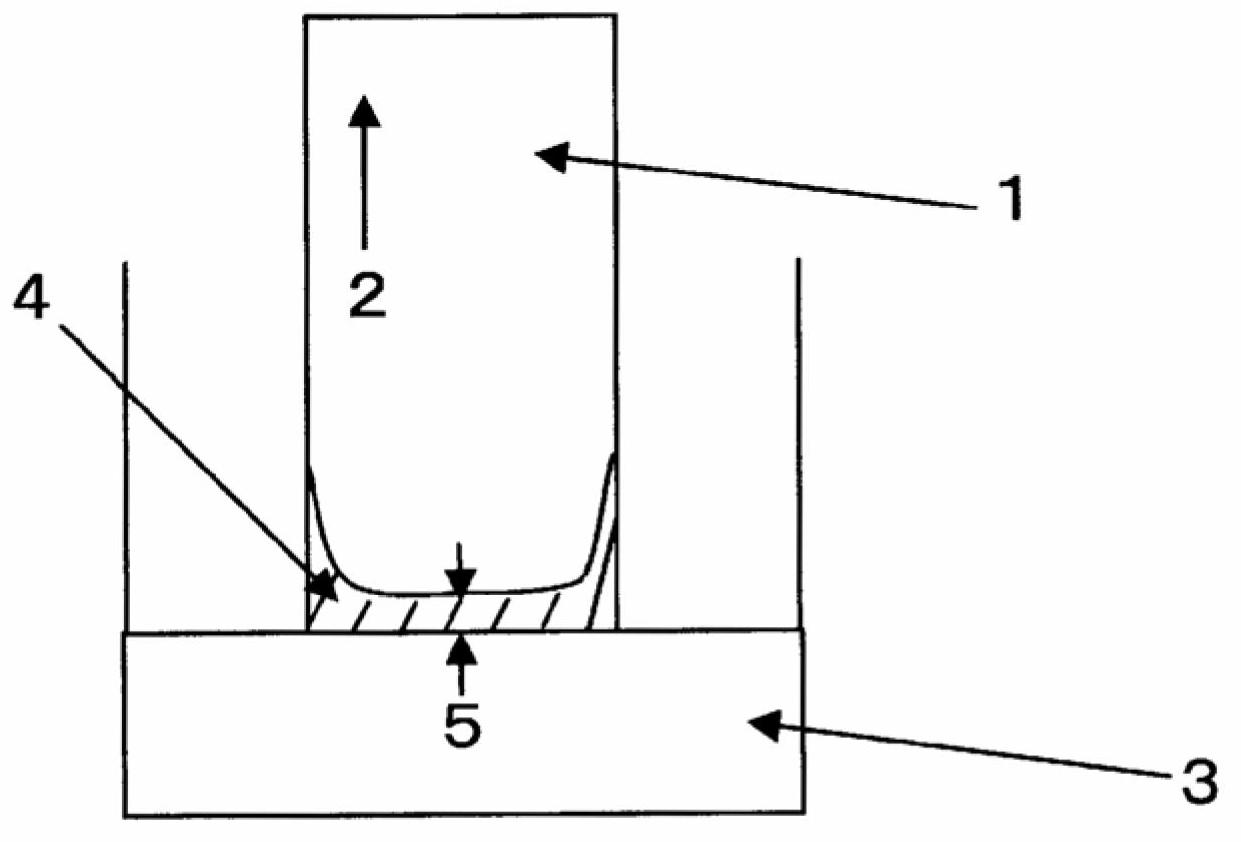

Image

Examples

Embodiment 1

[0156] First, pellets of resins A and B were prepared by blending the following composition at 300° C. with a twin-screw extruder.

[0157]

[0158] 92 parts by mass of homopolypropylene FLX80E4 (hereinafter, PP-1) manufactured by Sumitomo Chemical Co., Ltd., 1 part by mass of polypropylene PF-814 (hereinafter, HMS-PP) manufactured by Basell as a high melt tension polypropylene resin, and ethylene In addition to 7 parts by mass of "Engage" (registered trademark) 8411 (melt index: 18 g / 10 minutes or less, PE) manufactured by Dow Chemical Co., Ltd. of 1-octene, N as a β crystal nucleating agent , 0.2 parts by mass of N'-dicyclohexyl-2,6-naphthalene dicarboxamide (Nu-100 manufactured by Shin Nippon Chemical Co., Ltd.), and 0.15 parts by mass of "IRGANOX" ( registered trademark) 1010, 0.1 parts by mass of "IRGAFOS" (registered trademark) 168

[0159]

[0160] 99 parts by mass of homopolypropylene PP-1, 1 part by mass of high melt tension polypropylene HMS-PP, N,N'-dicyclohexy...

Embodiment 2

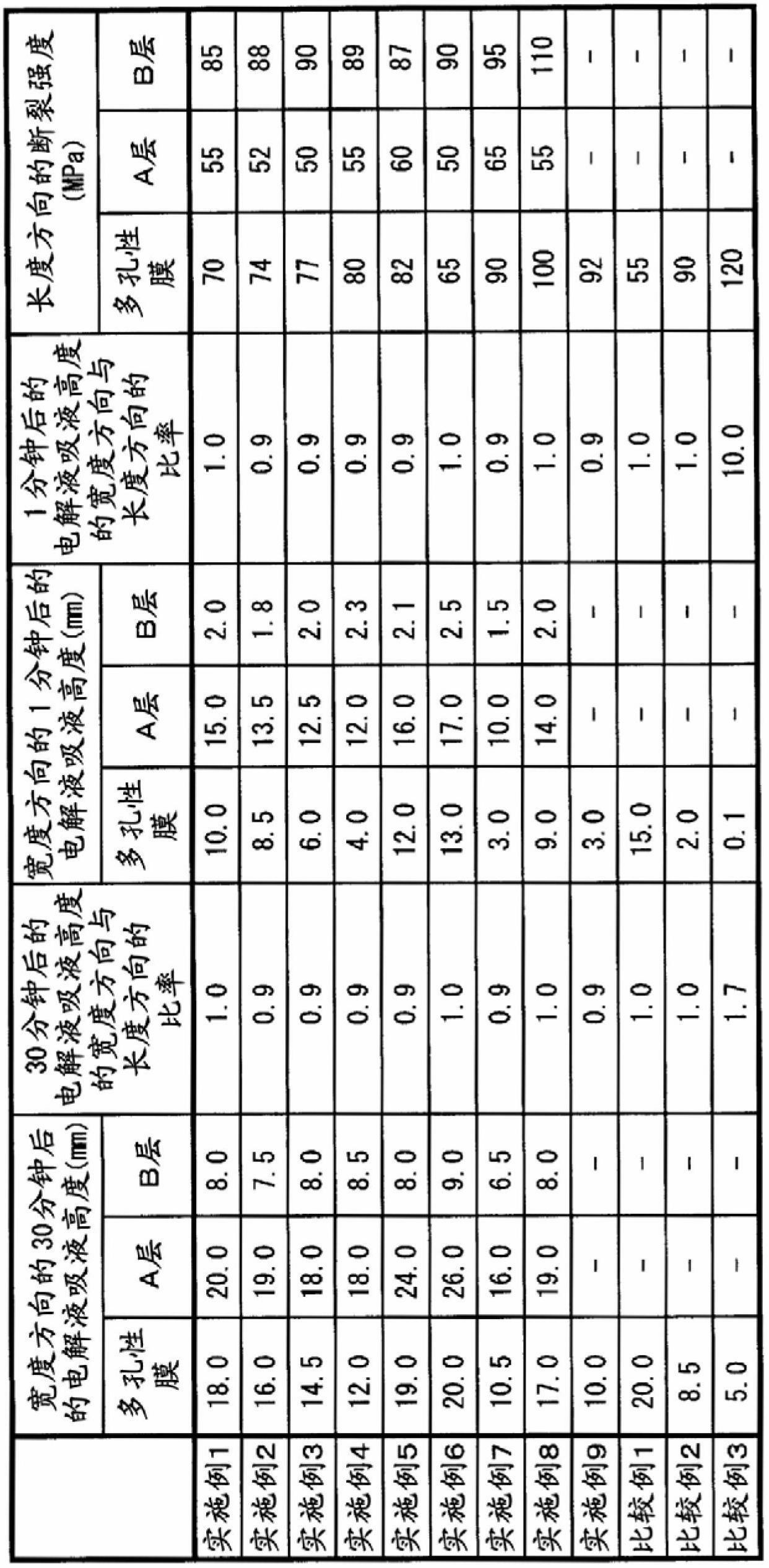

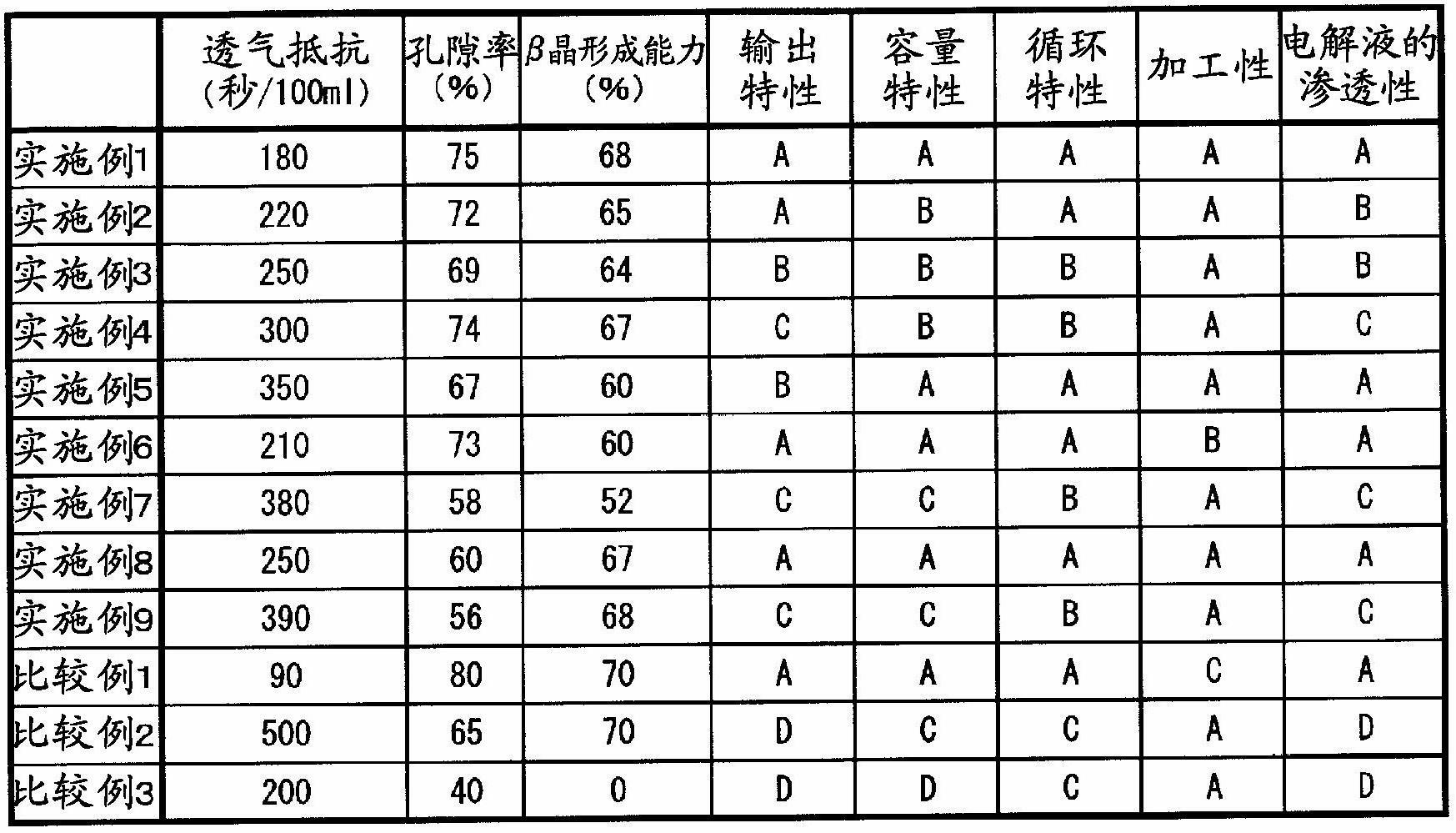

[0166] Except changing the lamination thickness ratio to 1 / 5 / 1, the same operation as in Example 1 was carried out to obtain a porous film with a thickness of 25 μm. Each physical property value is shown in Table 1 and Table 2.

[0167] The resulting porous film had a high liquid absorption of 16.0 mm in the electrolyte liquid absorption height after 30 minutes in the width direction, an air resistance of 220 seconds / 100 ml, a porosity of 72%, and an excellent battery with an output characteristic of A It has a high strength of 74 MPa of breaking strength in the longitudinal direction, and is excellent in workability as A. In addition, layer A is a liquid-absorbing layer, and layer B is a strength-maintaining layer. The liquid-absorbing height of the electrolyte solution after 30 minutes in the width direction of layer A is 19.0 mm, and the breaking strength in the longitudinal direction is 52 MPa. The liquid absorption height of the electrolyte after 1 minute is 7.5 mm, and ...

Embodiment 3

[0169] Except changing the lamination thickness ratio to 1 / 10 / 1, the same operation as in Example 1 was carried out to obtain a porous film with a thickness of 25 μm. Each physical property value is shown in Table 1 and Table 2.

[0170] The resulting porous film had a high liquid absorbency of 14.5 mm in the electrolyte liquid absorption height after 30 minutes in the width direction, an air resistance of 250 seconds / 100 ml, a porosity of 69%, and an excellent battery with an output characteristic of A It has a high strength at breaking strength of 77 MPa in the longitudinal direction, and is excellent in workability as A. In addition, layer A is a liquid-absorbing layer, and layer B is a strength-maintaining layer. The liquid-absorbing height of the electrolyte after 30 minutes in the width direction of layer A is 18.0 mm, and the breaking strength in the longitudinal direction is 50 MPa. The thickness of layer B in the width direction is 30 mm. The liquid absorption height...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com