Water-air coupled high-efficient irrigation system

A water-air coupling, irrigation system technology, applied in the field of agricultural irrigation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

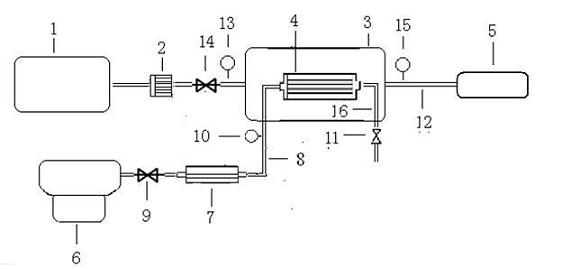

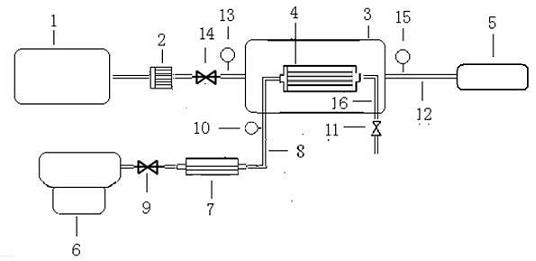

[0016] Example 1, see figure 1 Connect one end of the main water delivery pipe 12 to the water source 1, and communicate with the non-bubble aeration water-air mixing tank 3 with the hydrophobic hollow fiber membrane module 4, the non-bubble tank with the hydrophobic hollow fiber membrane module 4 The aeration water-air mixing tank 3 is composed of a non-bubble aeration water-air mixing tank body and an internal hydrophobic hollow fiber membrane module 4, and the hydrophobic hollow fiber membrane module 4 is in the non-bubble aeration water-air mixing tank Suspended in the body, the first air guide tube 8 and the second air guide tube 16 are fixed without swinging; the other end of the main water delivery pipe 12 is connected to each drip irrigation capillary that forms the dropper pipeline system, and each drip irrigation capillary can be placed on the surface or Buried in the ground, respectively constitute a water-gas coupling high-efficiency surface drip irrigation system...

Embodiment 2

[0017] Embodiment 2 is the same as Embodiment 1. The difference is that the other end of the main water delivery pipe 12 is directly placed in the water delivery ditch. When the water pump works normally, the system can realize furrow irrigation, border irrigation and flood irrigation under normal water supply conditions. High-efficiency surface irrigation with water-air coupling under common surface irrigation conditions.

Embodiment 3

[0018] Embodiment 3 is the same as Embodiment 1, except that the other end of the main water delivery pipe 12 is connected to the sprinkler irrigation water supply pipeline system. When the water pump is working normally, the system can realize water-air coupling and efficient sprinkler irrigation under normal water supply conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com