Processing method for normal-temperature storage of instant mussels

A technology of normal temperature storage and processing method, which is applied in the field of food processing, can solve the problems of soup color becoming mixed and spoiled, mussel meat shrinking and hardening, and the flavor is far away, so as to prolong the shelf life, maintain the flavor and color, and improve the flavor and taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

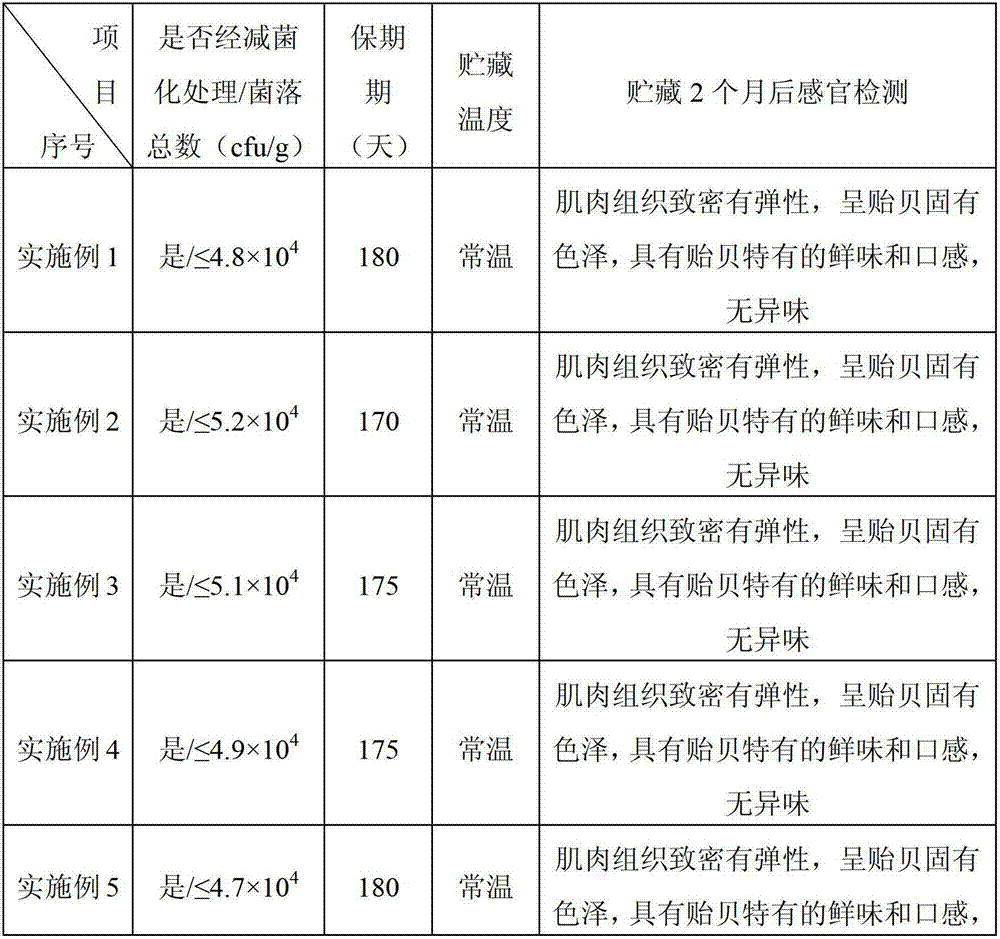

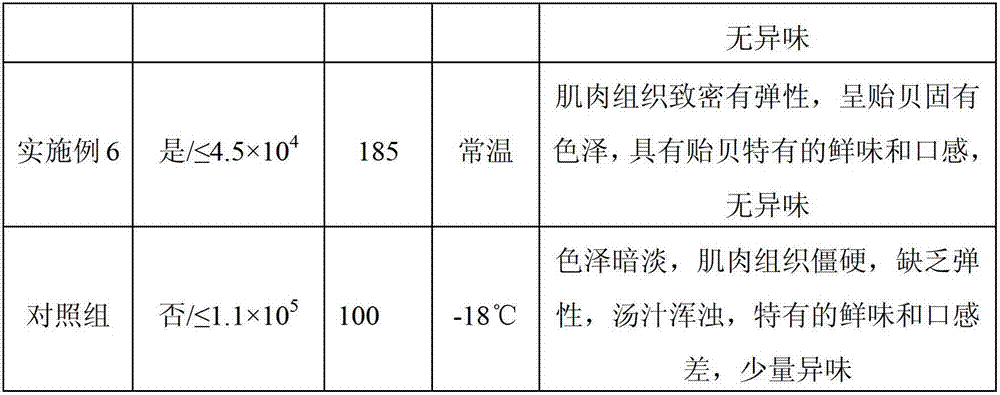

Examples

Embodiment 1

[0027] 1) Acceptance of raw materials: select fat and healthy live mussels as raw materials, and remove broken shells and dead mussels;

[0028] 2) Cleaning: Clean the attached sediment, algae, etc., and soak the mussels in 2% saline solution to remove the fishy smell of the sea;

[0029] 3) Bacteria-reducing treatment: Drain the cleaned mussels for 2 minutes, and store them in a refrigerator at -1±0.5°C for 30 minutes at ice temperature;

[0030] 4) Boil and remove the meat: Fish the mussels after the sterilization treatment into a clean 300L sandwich pot, add about 150L of water to boil, add about 75-80kg of mussels, and heat until the mussel shells open , the meat has been shaped and easy to peel, take it out quickly, and recycle the mussel soup for later use. Use a knife to remove the mussel meat, including the adductor muscle, and then remove the silk, paying attention to maintaining the integrity of the mussel tissue and the beauty of the meat;

[0031] 5) Seasoning: A...

Embodiment 2

[0039] 1) Acceptance of raw materials: select fat and healthy live mussels as raw materials, and remove broken shells and dead mussels;

[0040] 2) Cleaning: Clean the attached sediment, algae, etc., and soak the mussels in 2% saline solution to remove the fishy smell of the sea;

[0041] 3) Bacteria-reducing treatment: Drain the cleaned mussels for 2 minutes, and store them in a refrigerator at -1±0.5°C for 35 minutes at ice temperature;

[0042] 4) Boil and remove the meat: Fish the mussels after the sterilization treatment into a clean 300L sandwich pot, add about 150L of water to boil, add about 85-90kg of mussels, and heat until the mussel shells open , the meat has been shaped and easy to peel, take it out quickly, and recycle the mussel soup for later use. Use a knife to remove the mussel meat, including the adductor muscle, and then remove the silk, paying attention to maintaining the integrity of the mussel tissue and the beauty of the meat;

[0043] 5) Seasoning: A...

Embodiment 3

[0051] 1) Acceptance of raw materials: select fat and healthy live mussels as raw materials, and remove broken shells and dead mussels;

[0052] 2) Cleaning: Clean the attached sediment, algae, etc., and soak the mussels in 2% saline solution to remove the fishy smell of the sea;

[0053] 3) Bacteria-reducing treatment: Drain the cleaned mussels for 2 minutes, and store them in a refrigerator at -1±0.5°C for 45 minutes at ice temperature;

[0054] 4) Boil and remove the meat: Fish the mussels after the sterilization treatment into a clean 300L sandwich pot, add about 150L of water to boil, add about 65-70kg of mussels, and heat until the mussel shells open , the meat has been shaped and easy to peel, take it out quickly, and recycle the mussel soup for later use. Use a knife to remove the mussel meat, including the adductor muscle, and then remove the silk, paying attention to maintaining the integrity of the mussel tissue and the beauty of the meat;

[0055] 5) Seasoning: A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com