Preparation method of artificial microtube and application of artificial microtube as micromotor

A technology of artificial micro and micro motors, which is applied in the direction of mechanical equipment, microstructure technology, microstructure devices, etc., can solve the problems of small synthesis quantity at one time, difficult operation requirements of particle beam spraying method, and high cost, and achieve low cost and small size Controllable, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment one: the preparation method of the artificial microtube of the present embodiment is carried out according to the following steps:

[0015] 1. Preparation of metal catalytic particles;

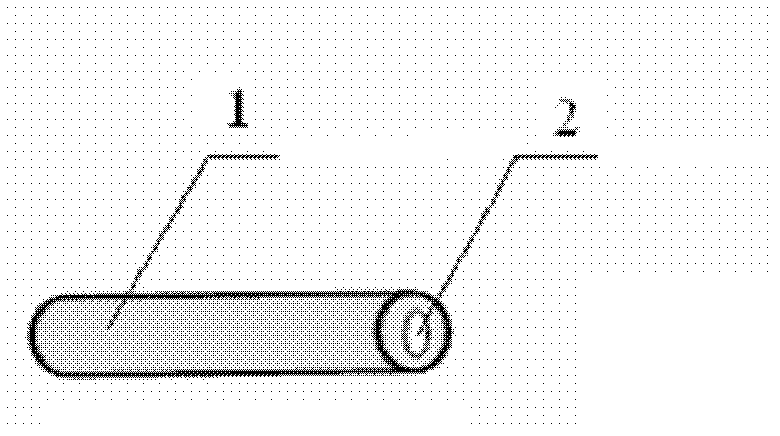

[0016] 2. Using a glass tube with a diameter of 0.2 mm to 5.0 mm as a template, assemble the polyelectrolyte layer into the hole of the template to obtain the skeleton of the microtube;

[0017] 3. Assembling the metal catalytic particles prepared in step 1 onto the skeleton of microtubules obtained in step 2 to obtain artificial microtubules.

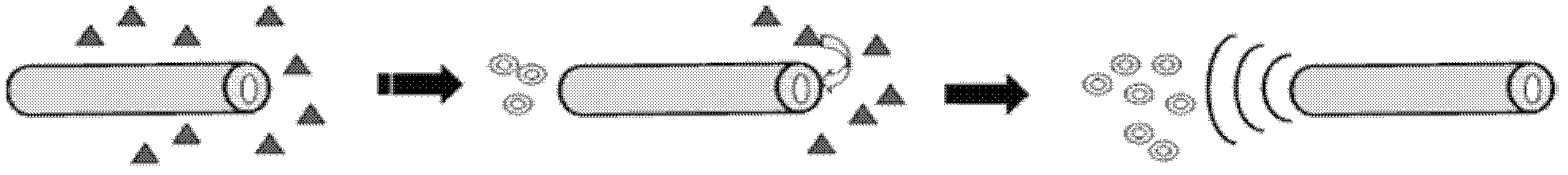

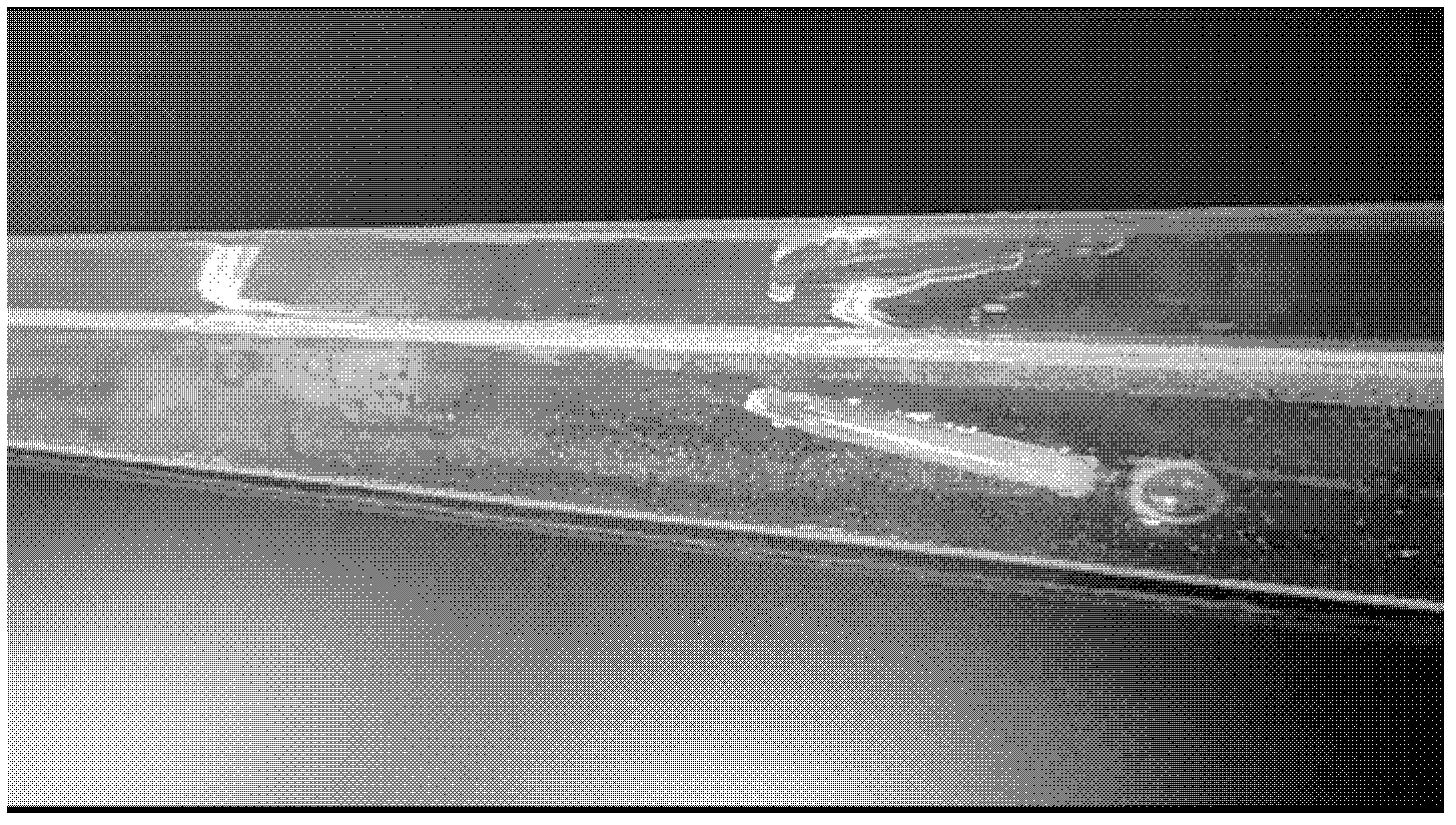

[0018] In this embodiment, platinum or silver micro-particles that catalyze hydrogen peroxide to decompose oxygen, templates for preparing microtubes, and artificial or natural polyelectrolytes for preparing microtubes are used as basic materials, and the polyelectrolyte microtubes and microtubes with Metal particles with catalytic performance are combined to prepare artificial microtubes. Put the artificial microtubes into ...

specific Embodiment approach 2

[0019] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the metal catalytic particles in step 1 are platinum particles with a particle size of 3nm to 100nm, silver particles with a particle size of 3nm to 100nm, or platinum or silver particles as the core Microparticles coated with citric acid or polydimethyldiallylammonium chloride with a particle size of 3nm to 100nm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the diameter of the glass tube in step 2 is 0.5 mm to 2.0 mm. Others are the same as in the first or second embodiment.

[0021] The glass tube of this embodiment is prepared by drawing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com