Heating disinfection method and device for microalgae cultivating water

A technology of microalgae cultivation and disinfection method, which is applied in the direction of heating water/sewage treatment, seawater treatment, non-polluted water treatment, etc., and can solve the problems of complex operation of equipment, lack of automatic control, effective disinfection temperature, disinfection duration and outlet water temperature Unable to accurately control and other problems, to achieve the effect of water outlet temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

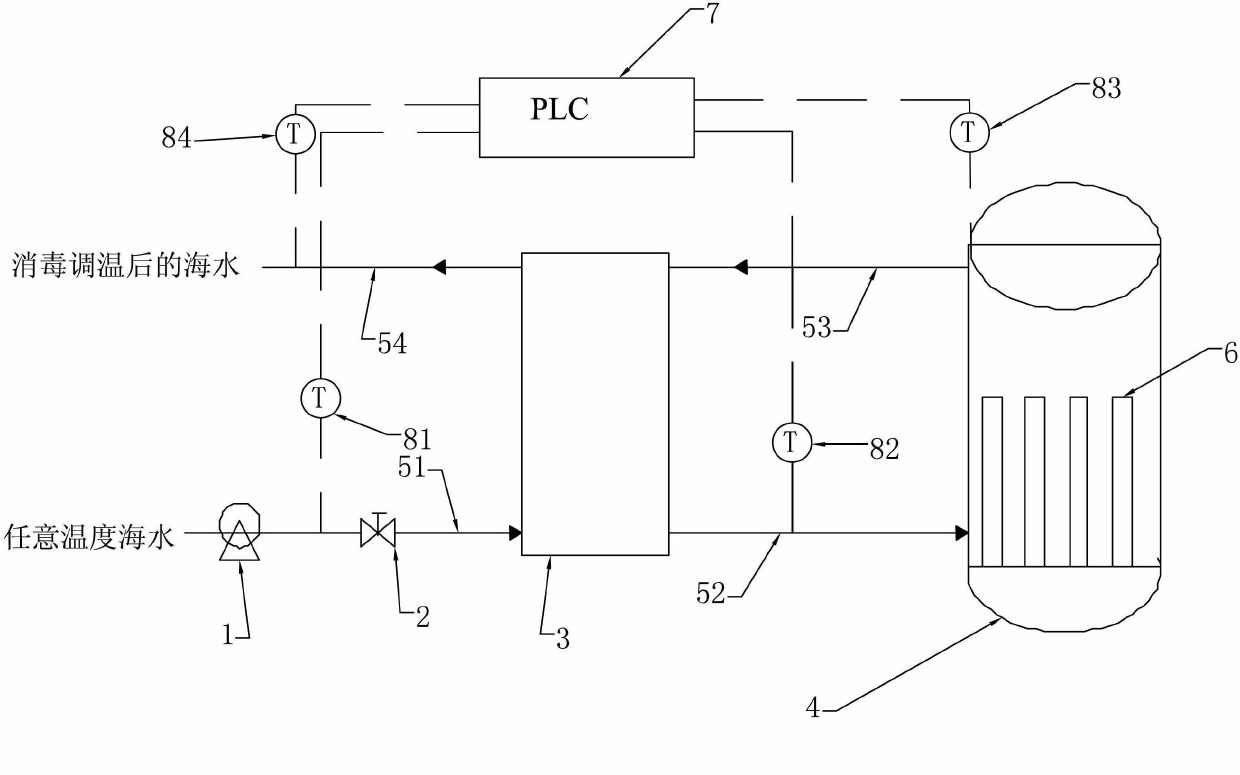

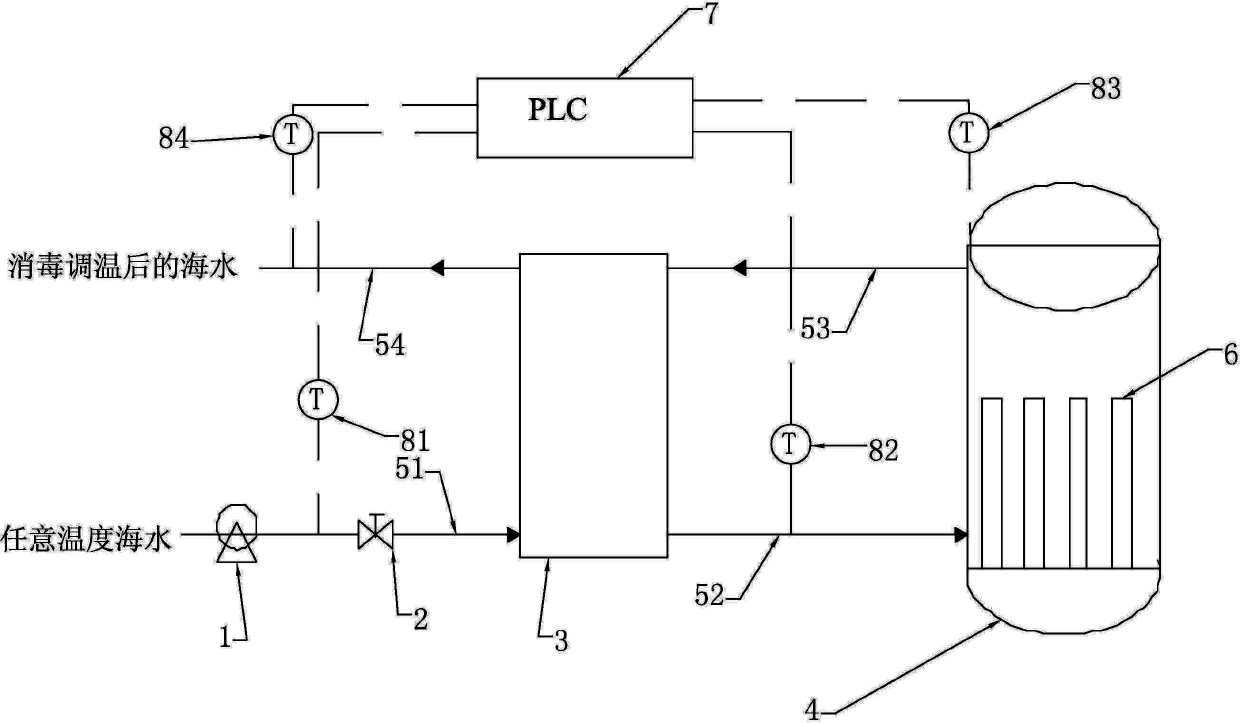

[0031] Such as figure 1 As shown, the heating and disinfection equipment for microalgae cultivation water of the present invention includes a water inlet pump 1, a flow regulating valve 2, a heat exchanger 3 and an electric heating furnace 4, and the outlet of the water inlet pump 1 passes through the first pipeline 51 to exchange heat with the heat exchanger 3 as a medium The inlet is connected, the flow regulating valve 2 is installed on the first pipeline 51, the outlet of the heat exchange medium of the heat exchanger 3 is connected with the inlet of the electric heating furnace 4 through the second pipeline 52, and the outlet of the electric heating furnace 4 is connected with the heat exchanger through the third pipeline 53 3. The material inlets are connected. The electric heating furnace 4 is provided with an electric heating rod group 6 composed of a plurality of electric heating rods. The material outlet of the heat exchanger 3 leads to the outside through the fourth ...

Embodiment 2

[0033] Taking Chlorella as an example, the cells of Chlorella are spherical or oval, with a diameter of 3 to 10 microns, and the diameter can reach 23 microns during the reproductive period. Chlorella can adapt to a wide range of salinity during the cultivation process. It can grow normally in the range of 0-36 mass‰, and can reproduce and grow rapidly in the temperature range of 10-36°C. The optimum growth temperature is 25 ~30°C, the suitable pH is 7.5~8.5, and under the optimum temperature conditions, the optimum light intensity is 10000lx.

[0034]By setting the parameters of the equipment in Example 1, the water for microalgae cultivation was heated to 94° C., and the water for microalgae cultivation was continuously sterilized in this temperature range for 25 seconds, and the sterilized water for microalgae cultivation was obtained after heat exchange and cooling. The water for cultivation is used in conjunction with photobioreactors. Under the conditions of 25-30°C, pH ...

Embodiment 3

[0037] Taking Isochrysis globosa as an example, Isochrysis globosa is a single-celled individual with naked cells. The salinity range that Isoflagellates adapts to is between 14 and 40 mass‰, and the optimum salinity is 30‰ , the optimum temperature range is between 20-25°C, the optimum light intensity is 1500-3000 meter candles, and the optimum pH is 8.

[0038] By setting the parameters of the equipment in Example 1, the water for microalgae cultivation was heated to 95°C, and the water for microalgae cultivation was continuously sterilized in this temperature range for 23 seconds, and the sterilized water for microalgae cultivation was obtained after heat exchange and cooling. The water for cultivation is used in conjunction with a photobioreactor. Under the conditions of 20-25°C, pH 8.0, light intensity of 2000 meter candles and controlled salinity of 14-40 mass‰, microalgae are conventionally cultured continuously for 3 months, 1000 The contamination rate of protozoa and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com