Method for preparing polysiloxane hydrogel with high moisture content

A polysiloxane and hydrogel technology, used in medical science, instruments, glasses/goggles, etc., can solve the problems of inability to obtain wearing comfort, short-term comfort effect, discomfort, etc., and improve surface wettability. Poor, reducing the effect of water loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] synthetic chemicals

[0049] 1. 2-Hydroxyethyl methacrylate (HEMA for short): Purchased from Sigma.

[0050] 2. N-vinylpyrrolidone (NVP for short): Purchased from Sigma.

[0051] 3. Methacrylic acid (MA): Purchased from Sigma.

[0052] 4. (Trimethylsilyloxy)-3-methacryloxypropylsilane (TRIS): Purchased from Sigma.

[0053] 5. CoatOsil: Purchased from Momentive.

[0054] 6. Ethylene glycol dimethacrylate (EGDMA): Purchased from Sigma Corporation.

[0055] 7. D1173 photoinitiator: purchased from Ciba Chemicals.

[0056] Preparation of polysiloxane hydrogel materials

example 1

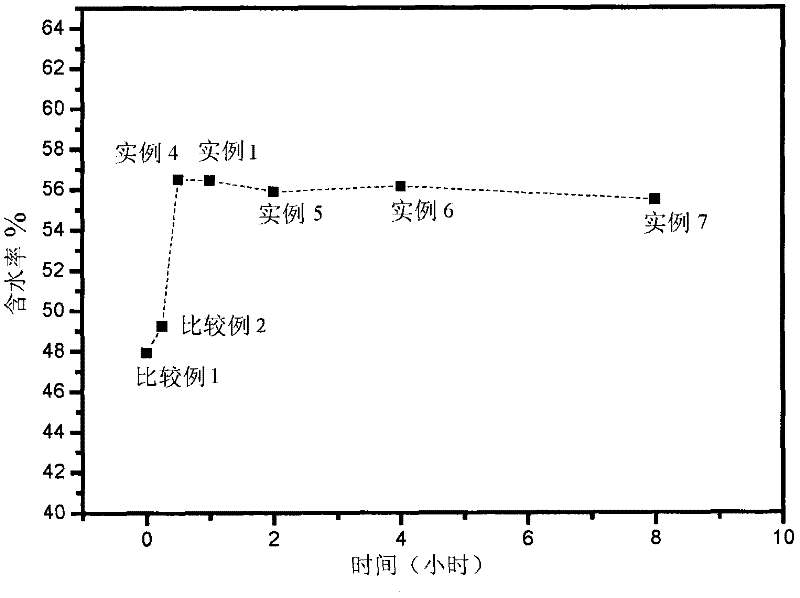

[0058] According to the composition and content shown in formula 1 in Table 1, the components were uniformly mixed, and cross-linked and polymerized by ultraviolet light for 60 minutes, and the completed polymer was soaked in 50% alcohol for 20 minutes, and then extracted with 70% alcohol for 60 minutes. minutes to remove unreacted monomer. Soak the prepared polysiloxane hydrogel film in sodium bicarbonate (NaHCO 3 ) solution for 60 minutes, then soaked in normal saline for 60 minutes for replacement, and finally placed the obtained film in normal saline and soaked for 120 minutes to reach the balance of water content.

example 2

[0060] The same feed ratio and reaction conditions as in Example 1, but the prepared polysiloxane hydrogel film was soaked in a sodium hydroxide (NaOH) solution with a pH of 9 for 60 minutes, and then soaked in physiological saline for 60 minutes. Replacement is carried out, and finally the obtained film is placed in physiological saline and soaked for 120 minutes to reach the balance of water content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com