Anti-aging polyvinyl chloride (PVC) film

A PVC film and formulation technology, applied in the field of anti-aging PVC film, can solve the problems of easy migration, extraction and volatilization of plasticizers, aging phenomenon, etc., achieve good synergistic effect, improve thermal aging resistance, and improve thermal aging resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1 Congo red, dynamic aging test of the sample containing calcium zinc stabilizer

[0015] The material formula used is: 100g PVC, 32g DOP, 16g PA, 4g ESO, 15g CaCO 3 , 2.5g calcium zinc stabilizer.

[0016] The test result of the Congo red tester is: the decomposition time of the sample containing calcium and zinc stabilizer is 61min.

[0017] The dynamic aging test results are: the aging time of the sample containing calcium zinc stabilizer is 85min.

[0018] The test results of Example 1 and Comparative Example show that the heat aging resistance of the calcium-zinc stabilizer is better than that of the barium-zinc stabilizer. In addition, the fluidity of the material is also better when the calcium-zinc stabilizer is used.

Embodiment 2

[0019] Example 2 Thermal stability synergistic effect test of ESO and PDOP in calcium-zinc stabilizer system

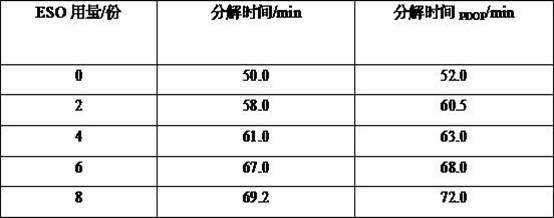

[0020] The material formula is: 100g PVC, 32g DOP, 16g PA, 15g CaCO 3 , 2.5g calcium zinc stabilizer, 0.8g PDOP, ESO is a variable, the decomposition time of the sample tested by the Congo red tester, the influence of ESO and PDOP on the decomposition time of the sample is shown in Table 1.

[0021] Table 1

[0022]

[0023] Note: Decomposition time PDOP It is the decomposition time of adding 0.8 parts of PDOP.

[0024] It can be seen from Table 1 that the combination system of ESO, PDOP and calcium-zinc stabilizer improves the thermal aging resistance of the sample. The amount of calcium-zinc stabilizer should also be determined with reference to other ingredients in the formula. If the amount is too small, the heat aging resistance of the sample will be poor, but if the amount is too large, it will easily cause blooming.

[0025] Can find out from embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com