Method of forming laser cladding layer on surface of upright post of hydraulic bracket

A technology of laser cladding and hydraulic support, which is applied in the direction of laser welding equipment, coating, metal material coating process, etc., to achieve the effect of efficient cladding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

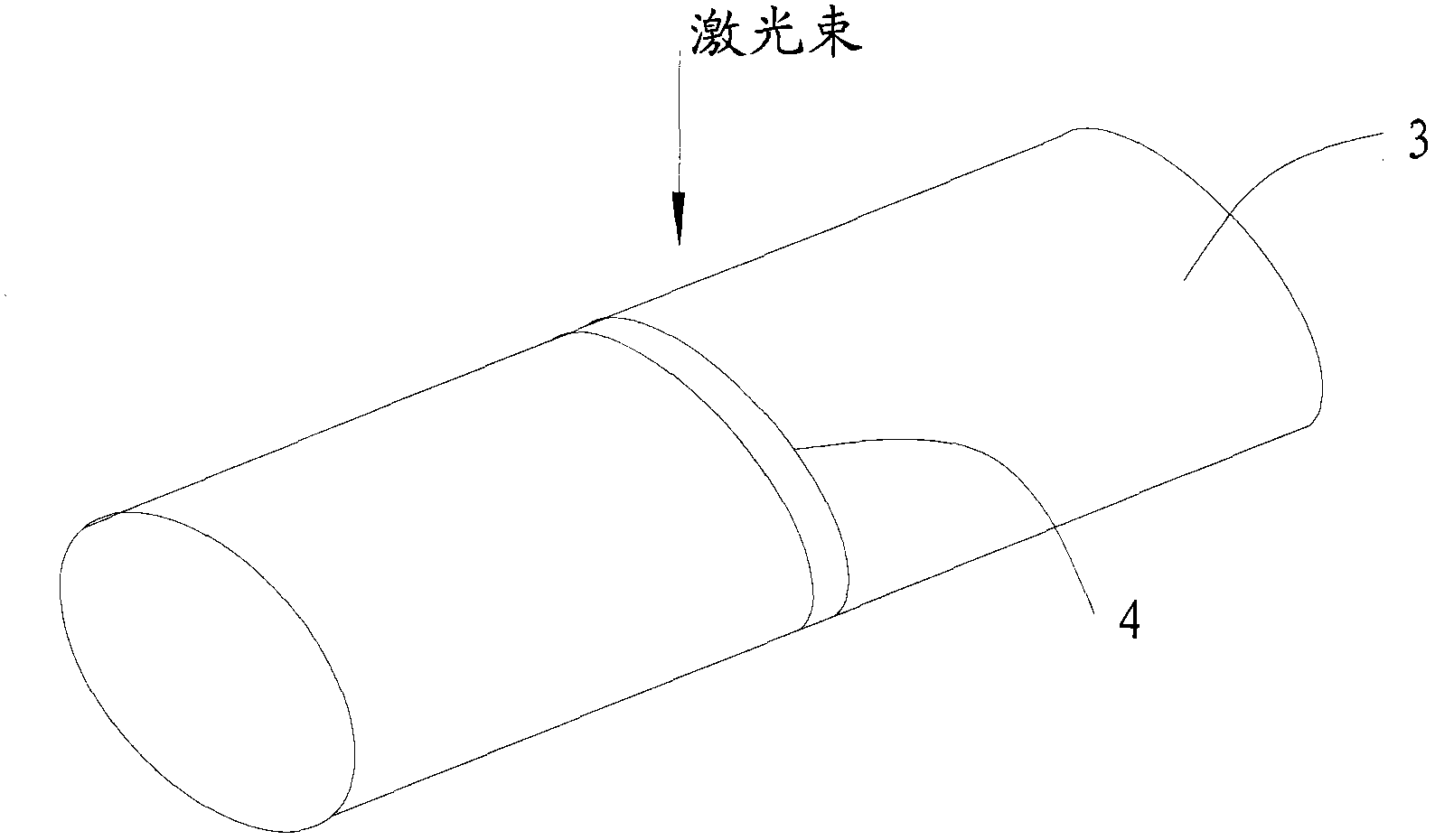

[0106]In addition to the above first embodiment, the present invention also provides a second embodiment, the difference between the second embodiment and the first embodiment is that the n-1th laser cladding tape 5, the nth laser cladding The extension direction of the cladding strip 4 and the n+1th laser cladding strip 6 is not perpendicular to the axial direction of the hydraulic support column, but spirals around the outer surface of the hydraulic support column.

[0107] third implementation

[0108] In addition to the above first embodiment, the present invention also provides a third embodiment. The difference between the third embodiment and the first embodiment is that the alloy powder used for laser cladding contains 0.08% C, 0.9 % Si, 0.6% Mn, 18.5% Cr, 23% Ni, the balance Fe and unavoidable impurities. In this embodiment, since it contains more Ni, the cost is higher, and the Rockwell hardness is only above 30. Therefore, the effect of the third embodiment is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com