Road pre-attached light reflective marking tape and manufacturing method thereof

A marking tape and reflective technology, applied in road signs, roads, roads, etc., can solve the problems of high labor intensity, low construction efficiency, short life, etc., and achieve the effect of reducing labor intensity, low cost and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

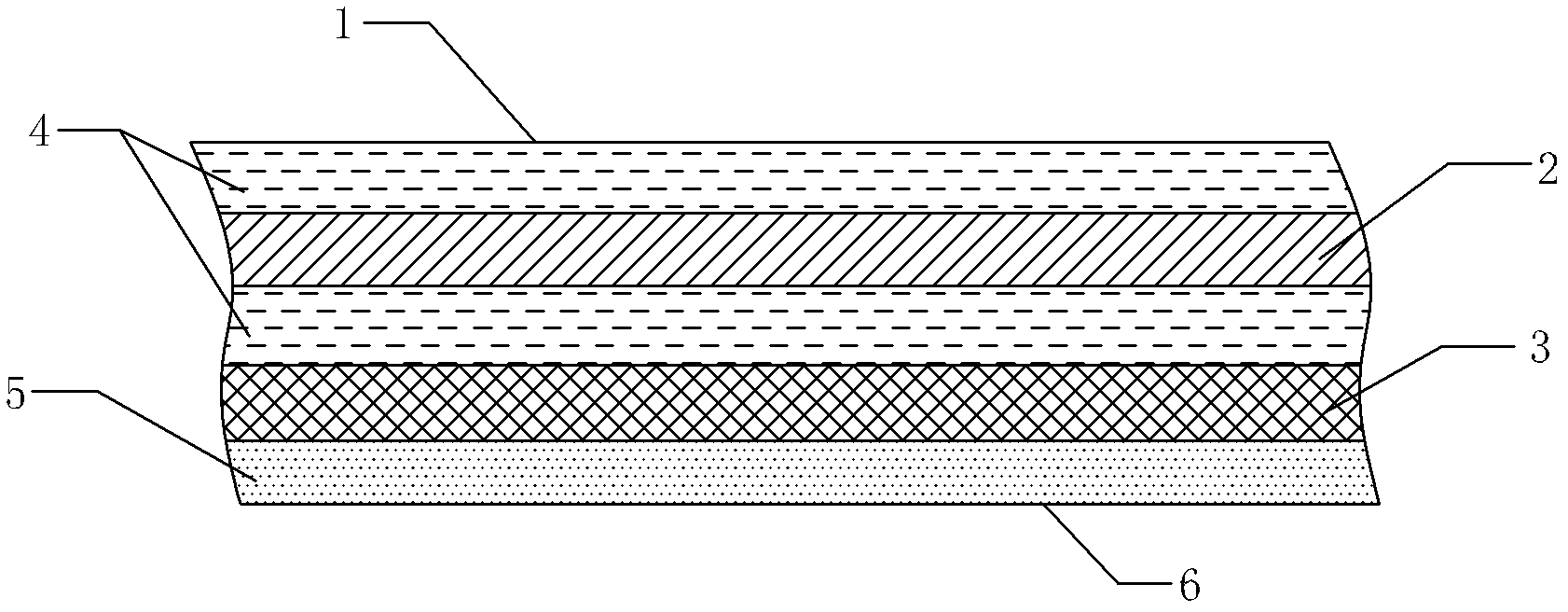

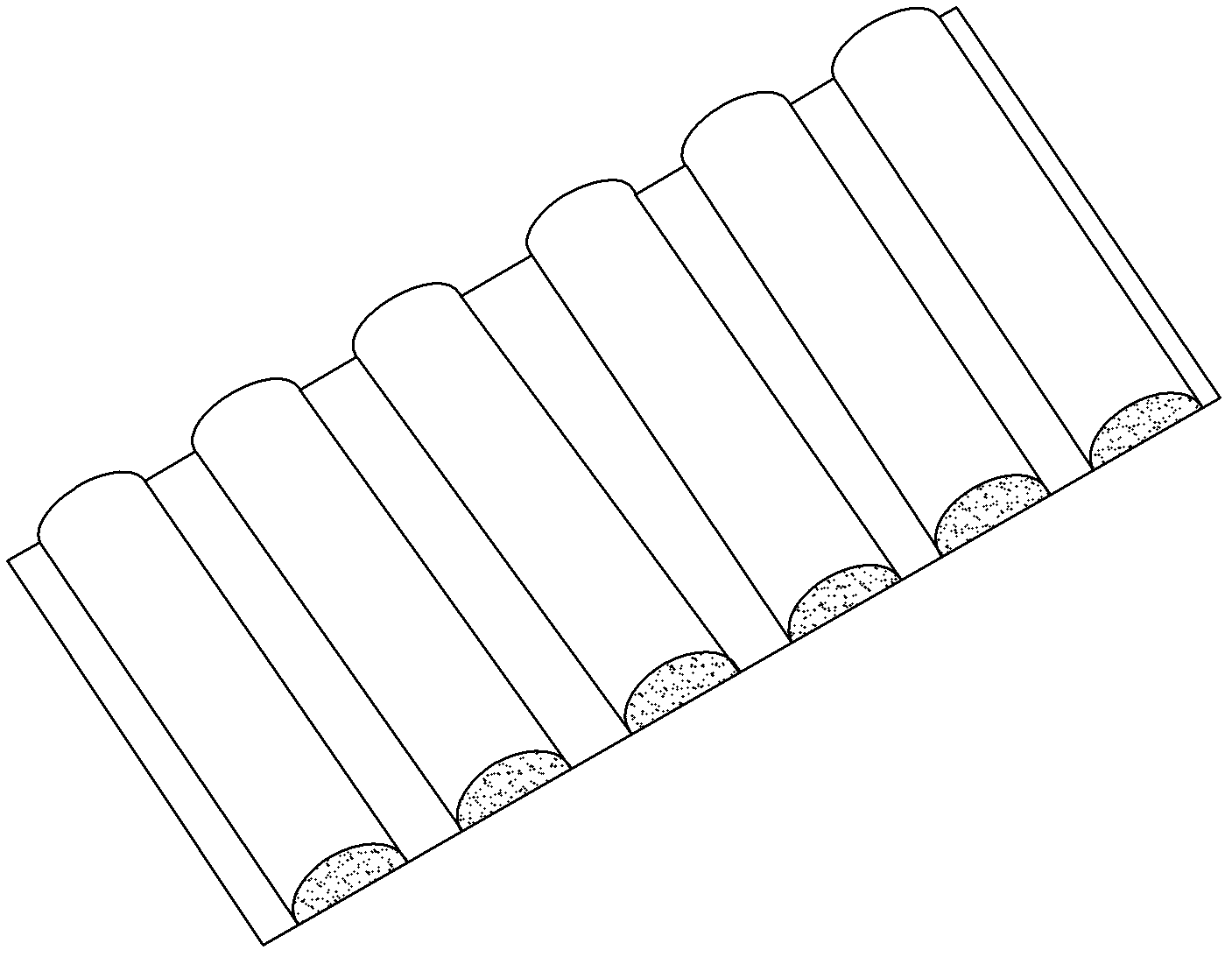

[0031] figure 1 with figure 2 Constitute the specific embodiment 1 of the present invention.

[0032] refer to figure 1 with figure 2 , the present embodiment includes a glass fiber layer 3, on the surface of the glass fiber layer 3, a plurality of arc-shaped ridges arranged regularly are formed, and the arc-shaped ridges have a multi-layer composite structure, including a transparent layer 1, a reflective layer 2 and a glass The fiber layer 3 is provided with an adhesive layer 4 at the junction of the transparent layer 1 and the reflective layer 2, and at the junction of the reflective layer 2 and the glass fiber layer 3, through which the transparent layer 1 and the reflective layer 2 It is connected with the glass fiber layer 3 to form an integral structure; the bow height of the arc-shaped convex lines is 1-2 mm, and the distance between the arc-shaped convex lines is 5-6 mm; a pressure-sensitive adhesive layer 5 is provided on the bottom of the glass fiber layer 3, ...

Embodiment 2

[0036] refer to figure 1 with image 3 , the main feature of this embodiment is: the arc-shaped convex line is truncated into several segments, forming an intermittent regular arrangement, and the interval formed between the segments is 6mm, 7mm, 8mm, 9mm or 10mm. All the other are with specific embodiment 1.

specific Embodiment 3

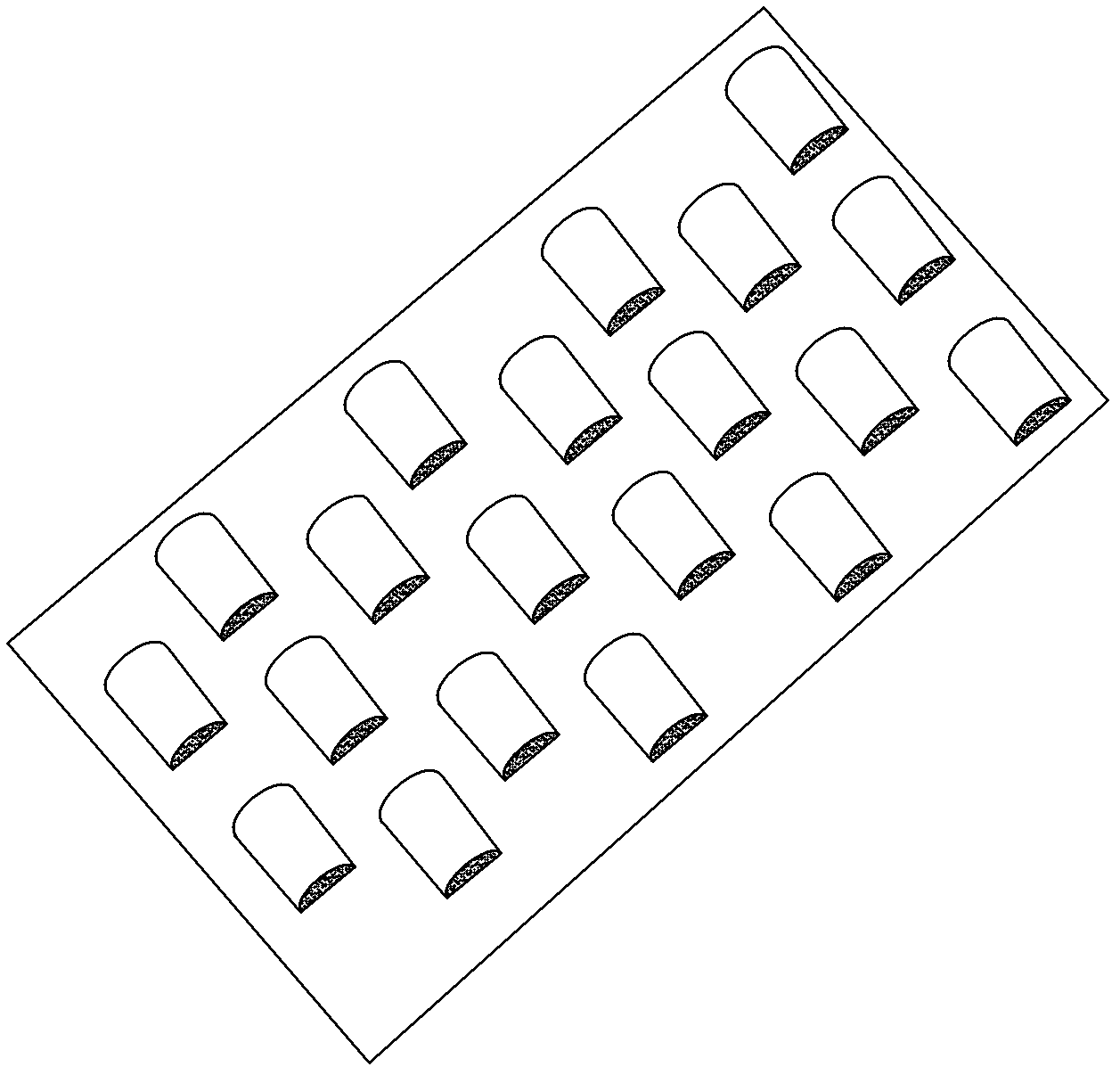

[0037] figure 1 with Figure 4 , Figure 5 Constitute the specific embodiment 3 of the present invention.

[0038] refer to figure 1 with Figure 4 , Figure 5, The main feature of this embodiment is: the reflective material layer 2 can be formed by a high-strength grade reflective film or a super-strength grade reflective film. Due to the high cost of high-strength reflective film and super-strong reflective film, the method of partial application is adopted. In the raised semicircular part of the reflective marking line, due to the excellent reflective function of the high-strength reflective film and the super-strong reflective film, the neutral part of the toothed bar is connected by the hazy light of the reflected light, but the visual light is still a whole. The luminescence of the reflective marking strip is mainly reflected by the 45° included angle of multiple semicircles. All the other are with specific embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com