Solid wood saw cutting composite floor board and processing technology

A composite floor and composite board technology, applied in the direction of floors, buildings, building structures, etc., can solve problems such as the inability to meet the requirements of consumers for higher quality products, reduce adverse effects on the environment and human body, reduce labor, The effect of saving manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

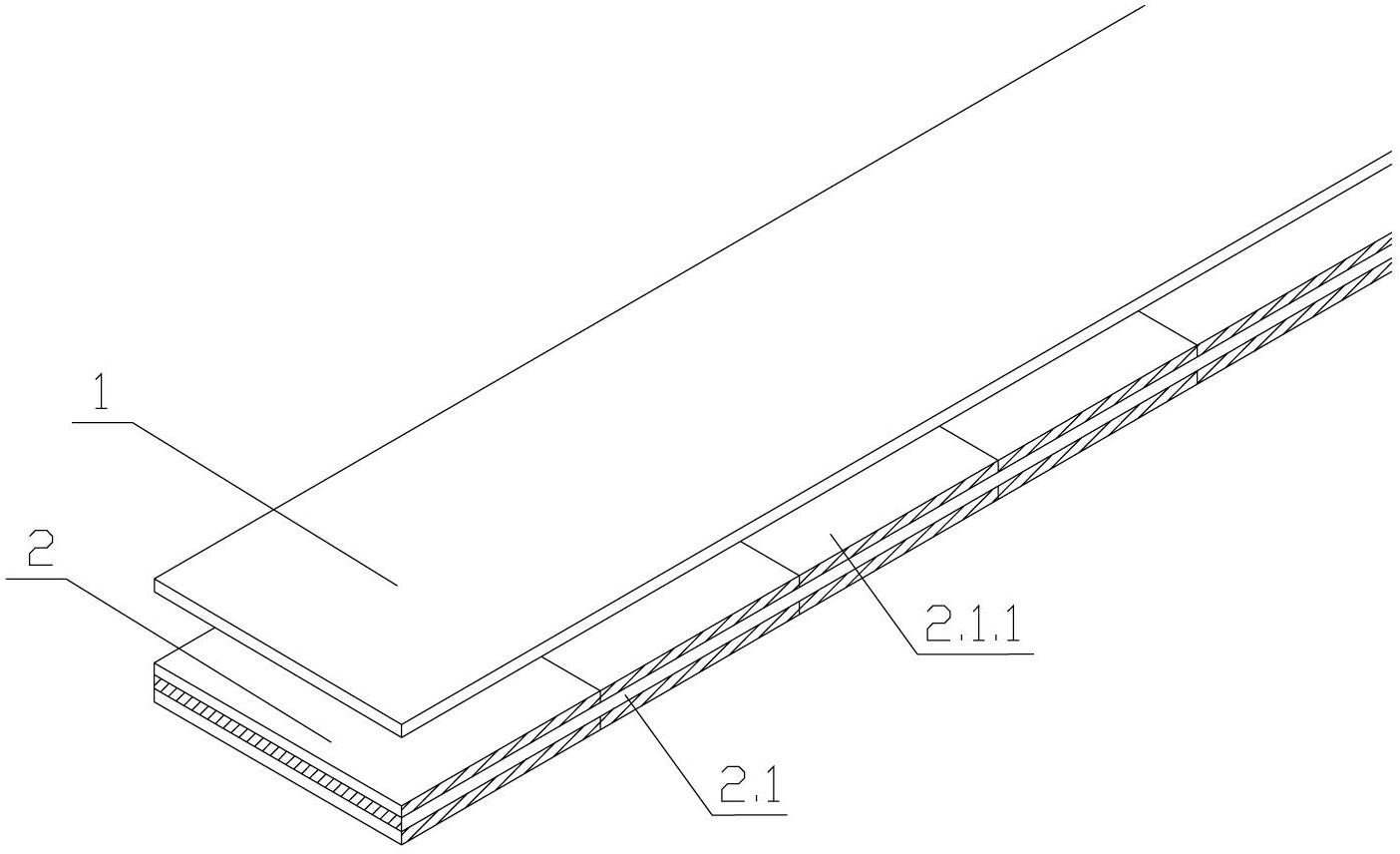

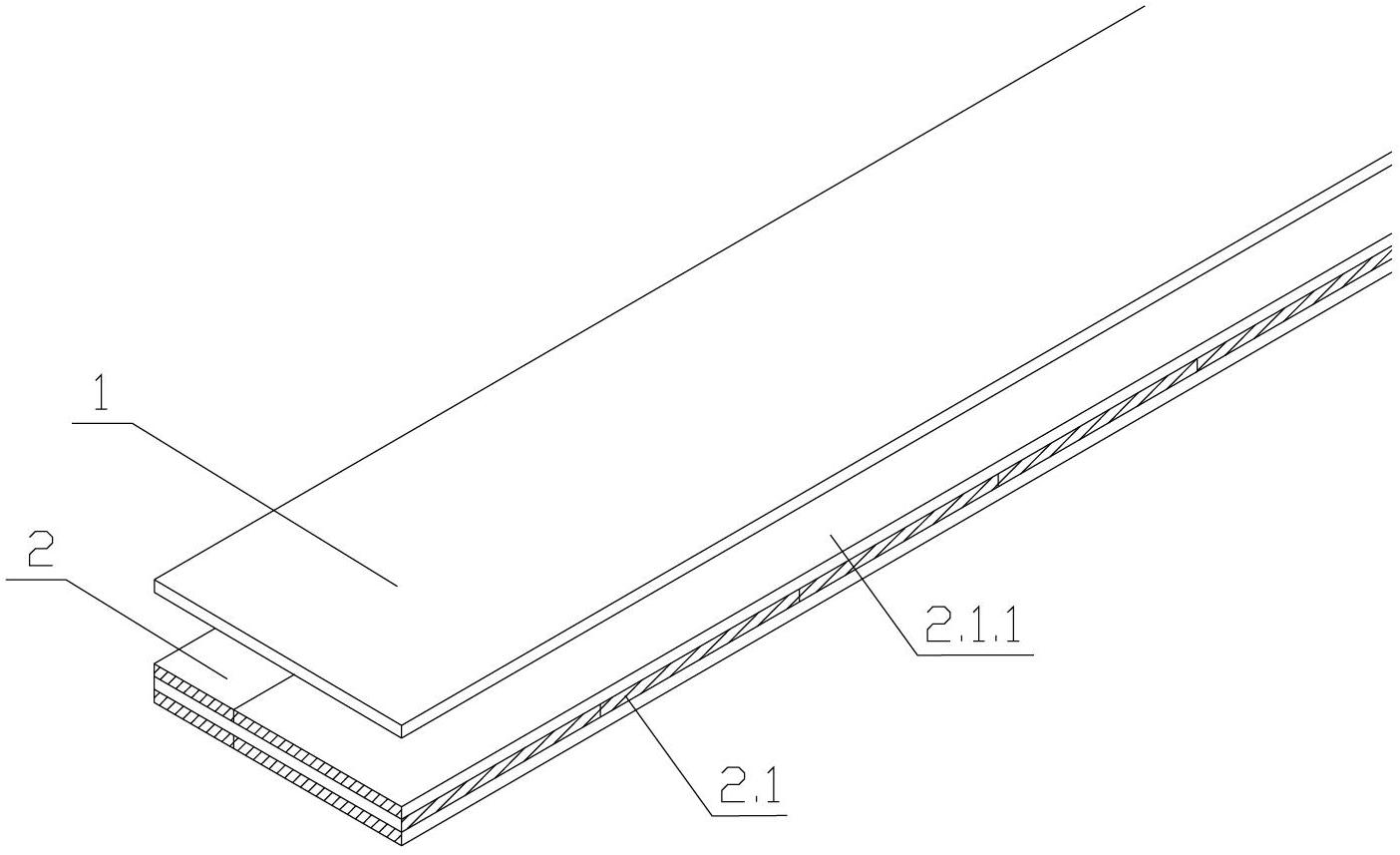

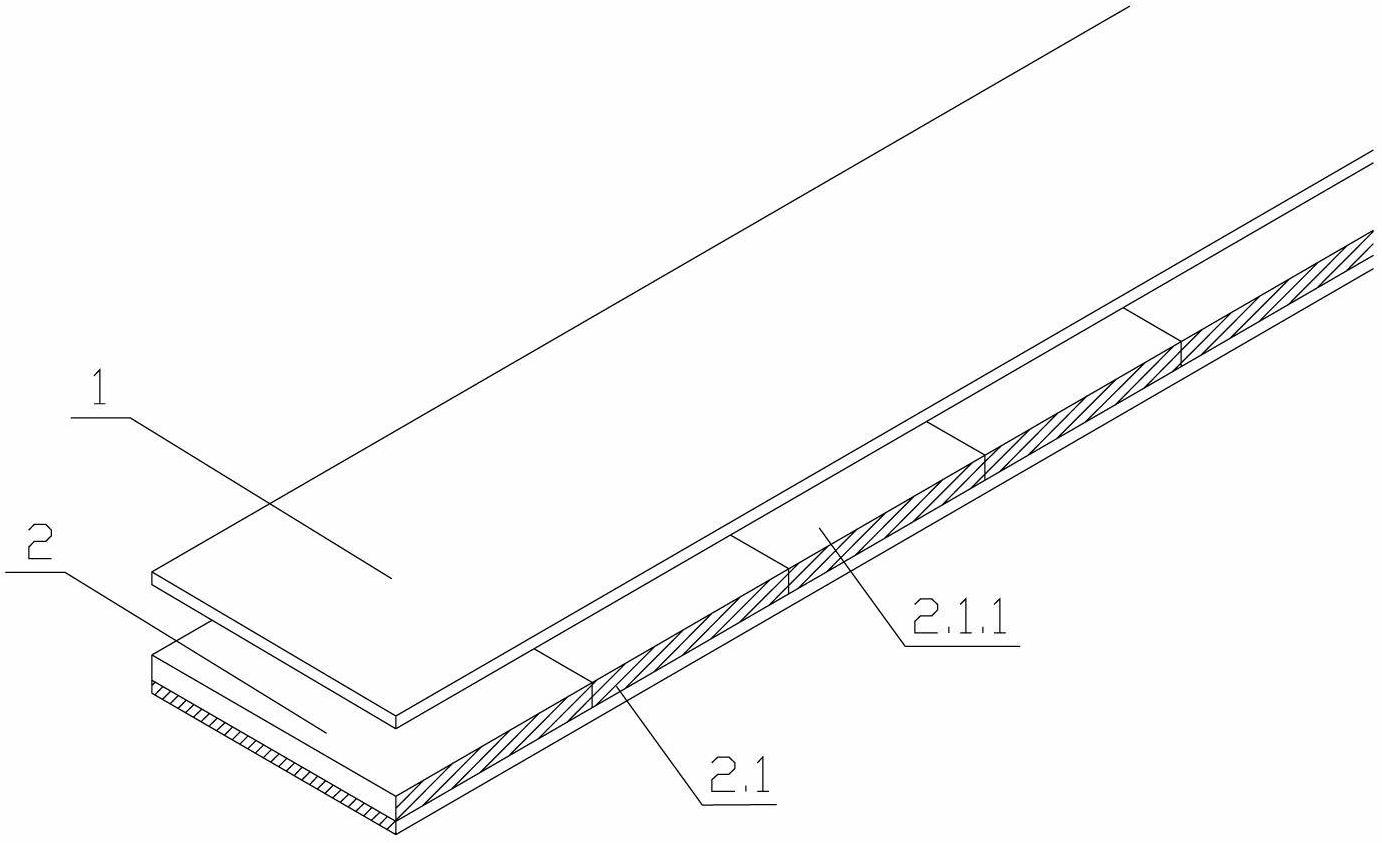

[0063] Specific examples of the present invention are attached image 3 , 4 As shown, it is composed of a surface plate 1 and a base material 2, and the surface plate 1 and the base material 2 are bonded and compacted by an adhesive; it is characterized in that the base material 2 is a two-layer single-layer solid wood sawing compound Board 2.1 is a solid wood sawn composite board formed by adhesive bonding and compaction; single-layer sawn solid wood composite board 2.1 is a sawn solid wood veneer 2.1.1 aligned and tiled after the edges are aligned, and the edges are passed through The substrate 2 and the surface plate 1 are bonded and compacted by the adhesive.

[0064] The two-layer single-layer solid wood sawn composite board 2.1 adjacent to the base material 2 is laminated vertically or parallel to the dislocation of the fiber direction; the adhesive can use different types of glue according to different needs, such as urea-formaldehyde glue, phenolic glue , Modified me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com