Omnibearing 3D (Three-Dimensional) modeling system based on initiative omnidirectional vision sensor

A 3D modeling and panoramic vision technology, applied in 3D modeling, instruments, photogrammetry/video surveying, etc., can solve the problems of high consumption of computer resources, low practicability and low robustness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

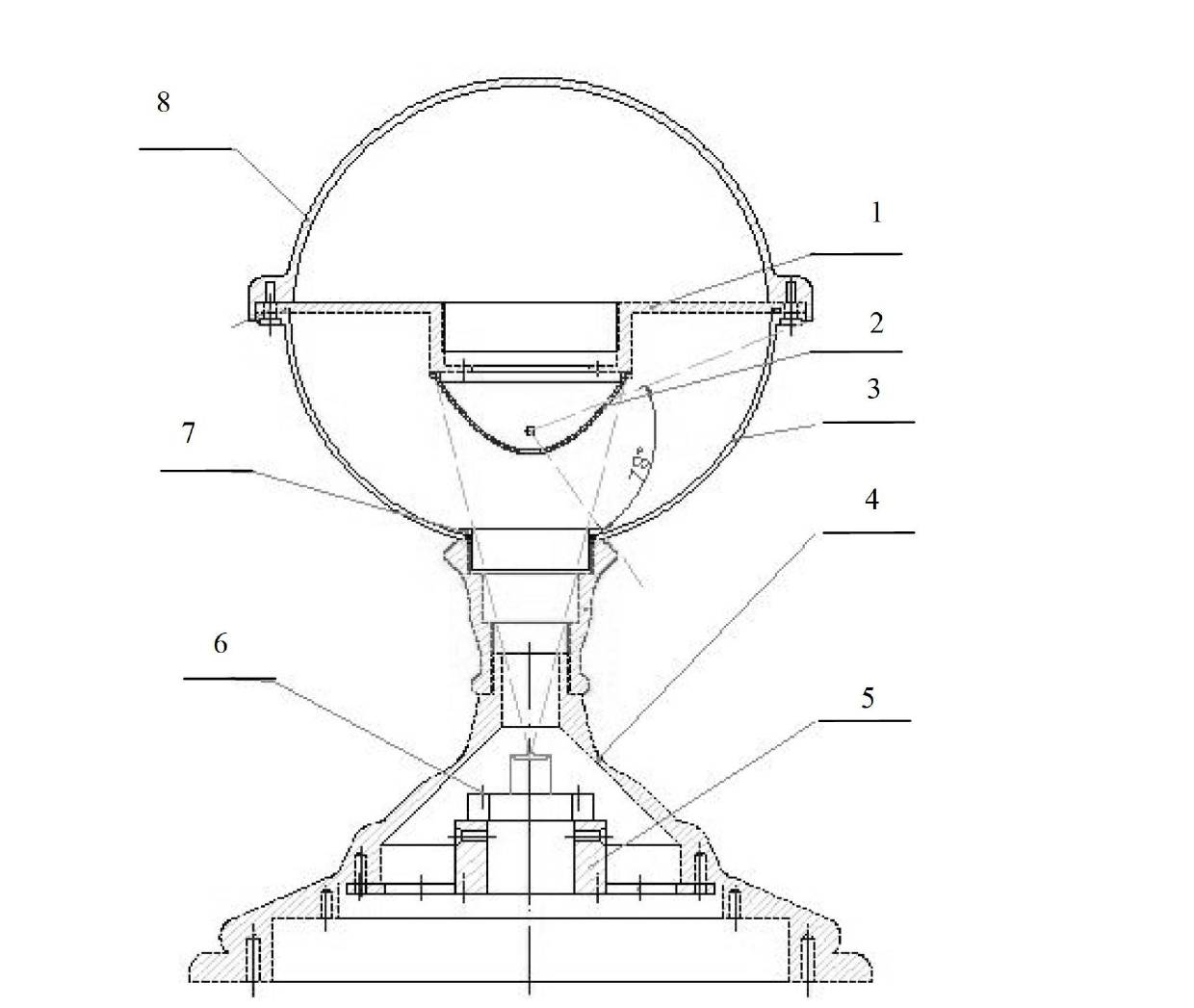

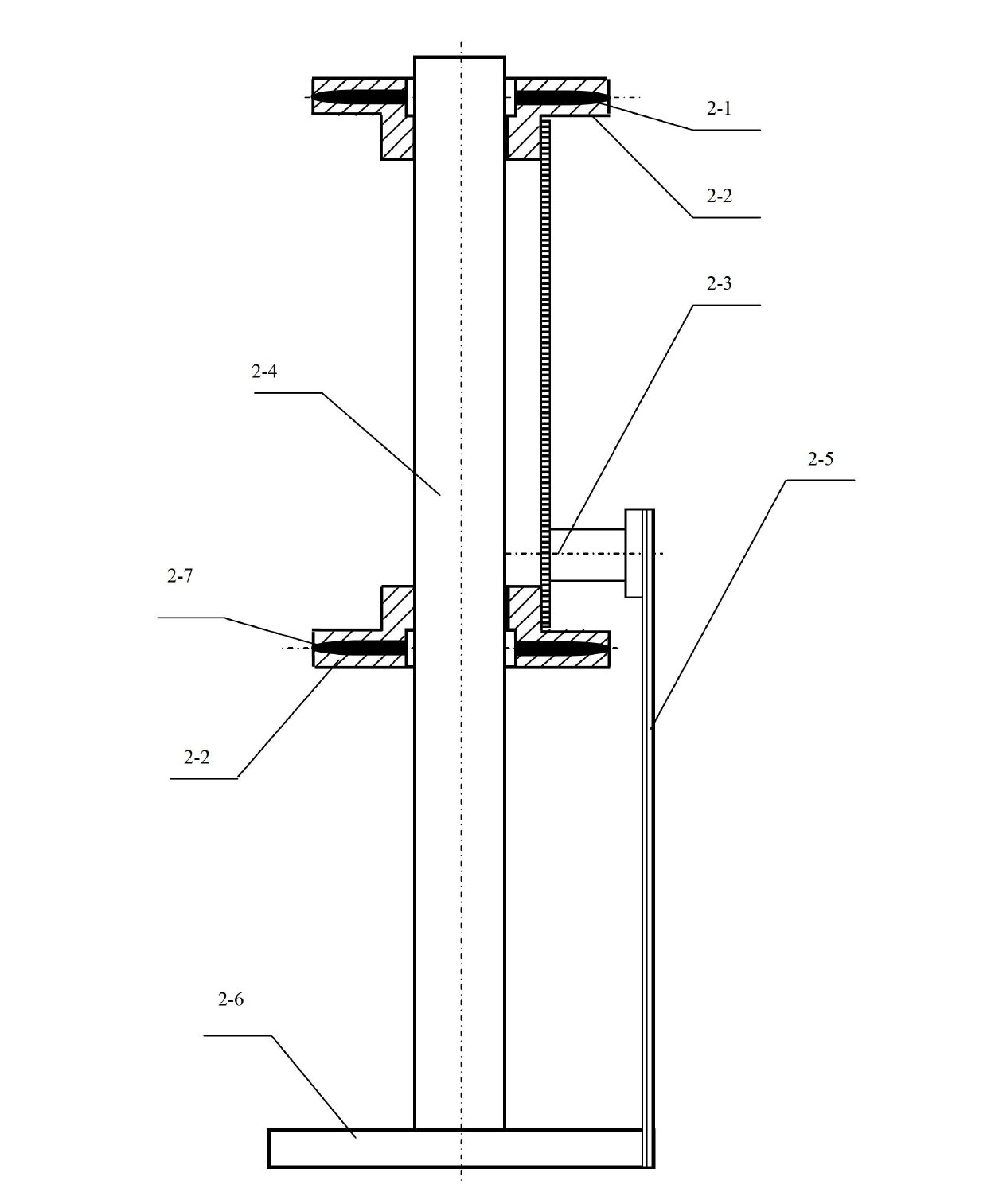

[0104] refer to Figure 1-12 , an omnidirectional three-dimensional modeling system based on an active panoramic vision sensor, including an omnidirectional vision sensor, a moving surface laser light source, and a microprocessor for 3D panoramic reconstruction of omnidirectional images, said omnidirectional vision sensor The center of the center and the center of the moving surface laser light source are configured on the same axis; the omnidirectional visual sensor includes a hyperboloid mirror 2, an upper cover 1, a transparent semicircular outer cover 3, a lower fixing seat 4, and a camera unit Fixing seat 5, camera unit 6, connection unit 7, upper cover 8, as attached figure 1 As shown; the hyperboloid mirror 2 is fixed on the upper cover 1, and the connecting unit 7 connects the lower fixing base 4 and the transparent semicircular cover 3 into one body, and the transparent semicircular The circular outer cover 3 is fixed together with the described upper cover 1 and the...

Embodiment 2

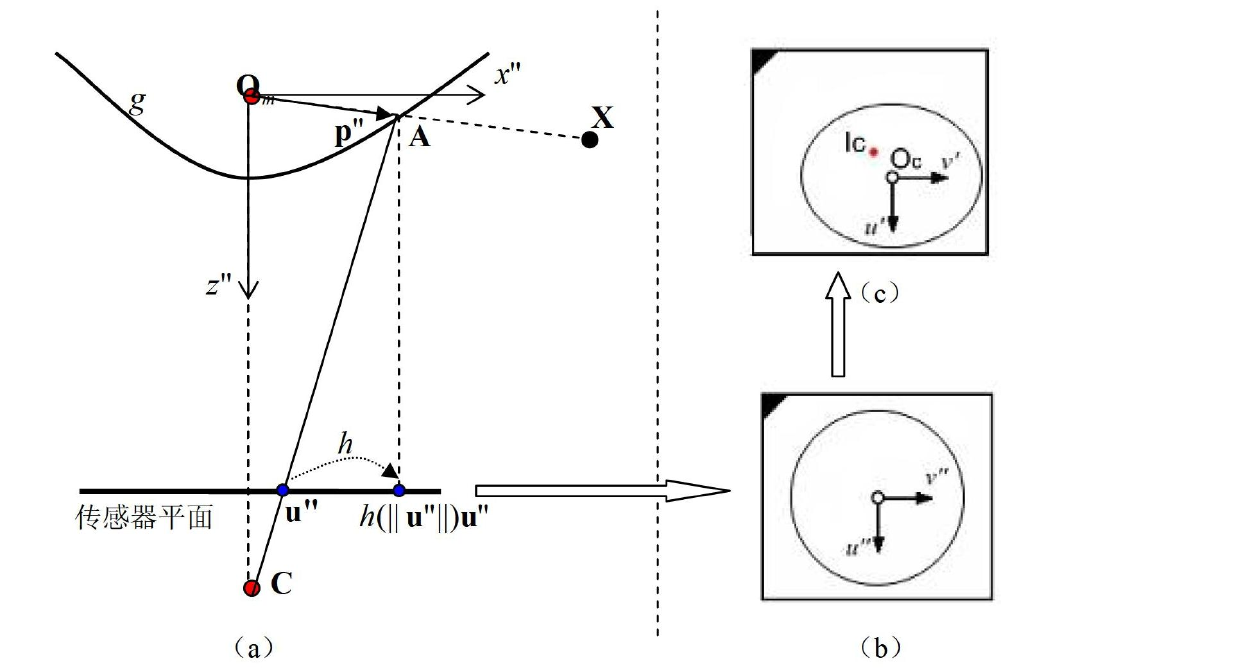

[0192] refer to Figure 1~Figure 12 , in this example, the point cloud point in Cartesian coordinate system to represent, its calculation method is given by formula (14),

[0193] x b ( z move ( j ) ) = h redlazer ( z move ( j ) ) × cos β × ( | | u ′ ′ | | ( β ) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com