Differential measurement method and device for arc current density

A technology of differential measurement and arc current, which is applied in the direction of current density measurement, etc., can solve the problems of missed detection and jumping, and achieve the effects of preventing missed detection and sudden change, saving costs, and improving data accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

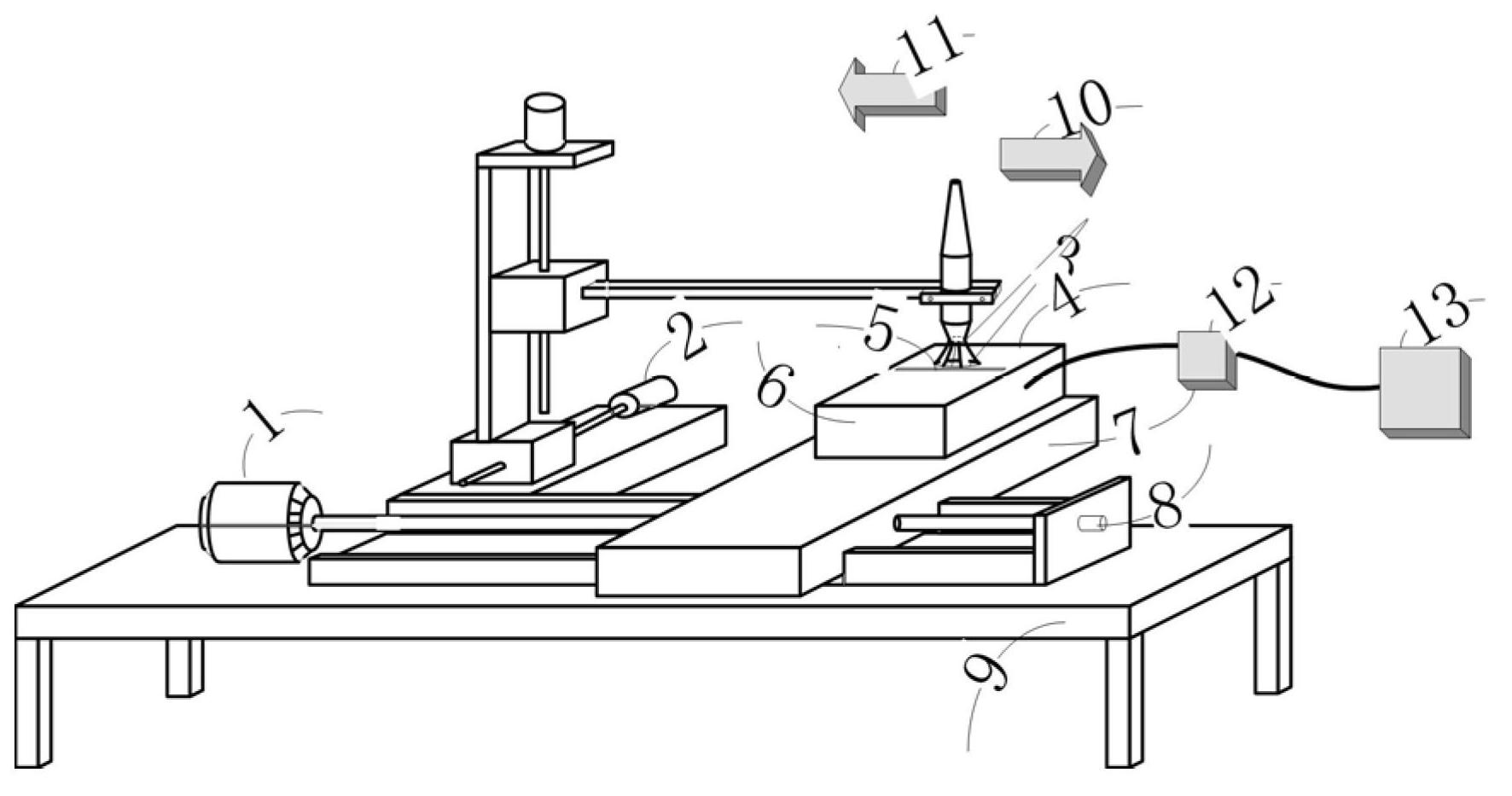

[0022] The present invention is a test method for arc current density distribution, and the test system also includes a TIG welding machine, a space wave module 12 and a computer processing system 13 . The second motor 1 is connected with the second leading screw 8 and then connected with the motion auxiliary block 7, and the welding torch is fixed on the workbench 9 and is perpendicular to the current sensor 6, as figure 1 shown.

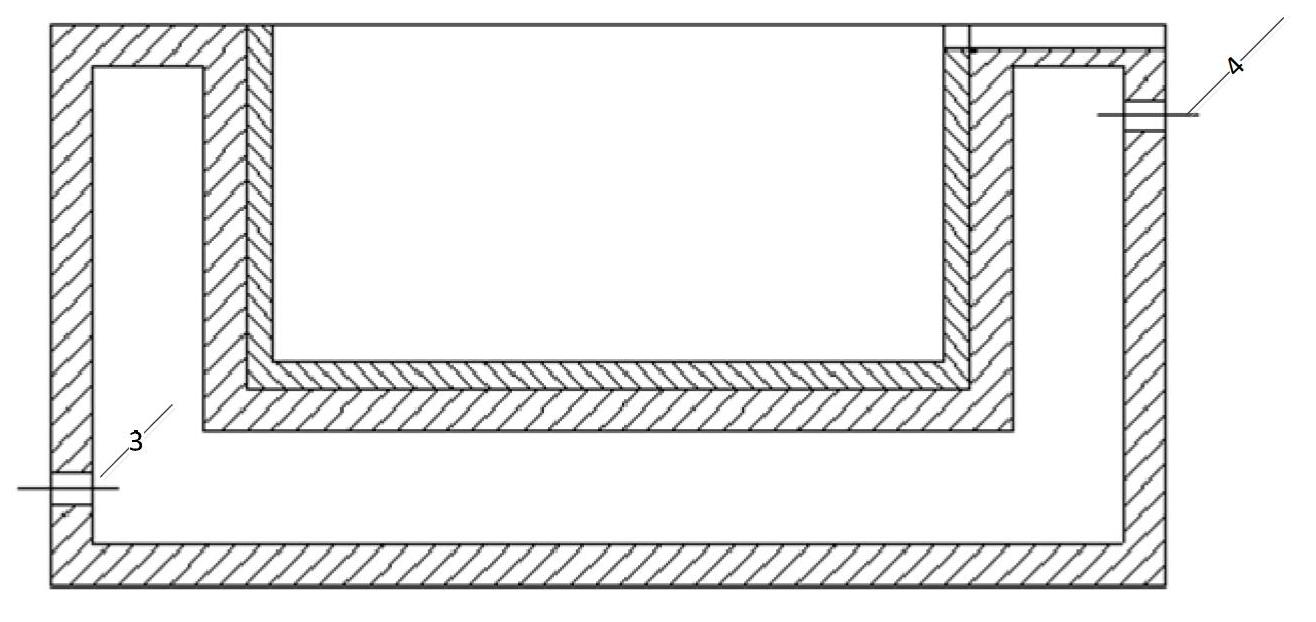

[0023] The arc is generated by the circuit formed between the TIG torch and the upper receiving copper plate 4. The upper receiving copper plate 4 is installed on the top of the current sensor 6, and the upper receiving copper plate 4 absorbs heat to protect the current sensor 6 from direct contact with the arc 3 for a long time. The outer layer of the current sensor 6 is made of aluminum alloy, which shields external interference signals and ensures that the internal signals of the current sensor 6 are provided by the penetration part of the slit ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com