Device for improving properties of light spot of super-resolution phase board

A phase plate and super-resolution technology, applied in optics, optical components, nonlinear optics, etc., can solve problems such as reducing signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

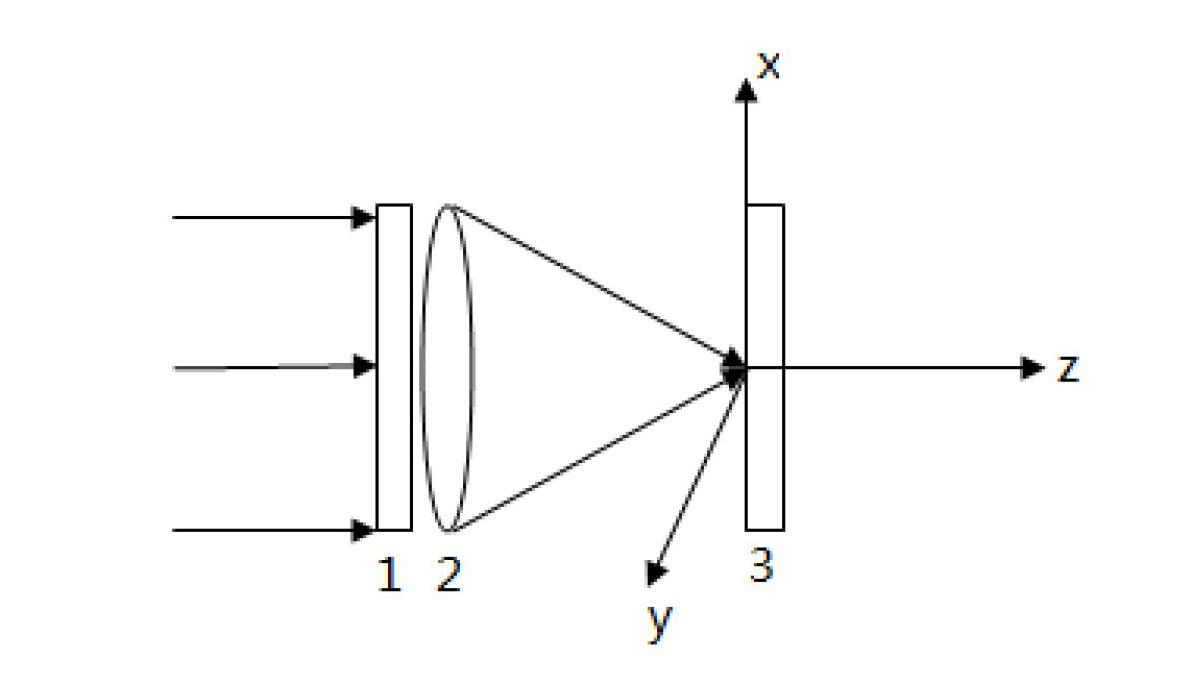

[0015] figure 1 It is a structural principle diagram of a specific embodiment of the present invention. Depend on figure 1 It can be seen that the composition of the device for improving the spot performance of the super-resolution phase plate in the present invention: along the beam advancing direction, there are three-ring pure phase type super-resolution phase plate 1, objective lens 2 with numerical aperture NA=0.95, Sb 2 Te 3 Non-linear saturable absorption film 3, the normalized radius of the three-ring phase-only super-resolution phase plate 1 is r1=0.13, r2=0.47, r3=1; the phases of the three regions are: φ 1 =0, φ 2 = π, φ 3 =0; the objective lens 2 is in close contact with the three-ring pure phase super-resolution phase plate 1, and the Sb 2 Te 3 The nonlinear saturable absorption film 3 is located at the focal plane of the objective lens 2, the Sb 2 Te 3 The selection range of the thickness of the nonlinear saturable absorption film is 10~100nm, and the lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com