Liquid level control method of steel slag desulfurization agent storage tank

A technology of liquid level control and desulfurizer, applied in liquid level control, non-electric variable control, control/regulation system, etc., can solve the failure of steel slag desulfurizer control equipment, the inapplicability of steel slag desulfurizer, the failure of liquid level electrode points, etc. problems, to achieve the effect of low power consumption, use of remote control, and good security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

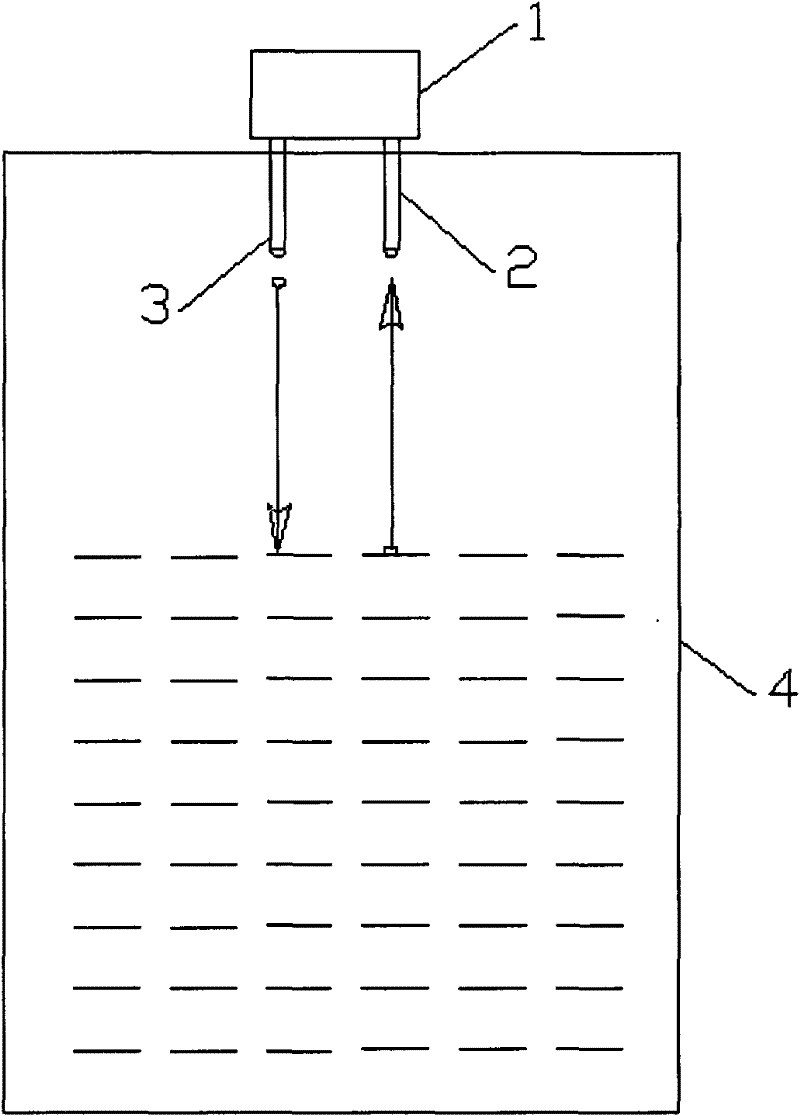

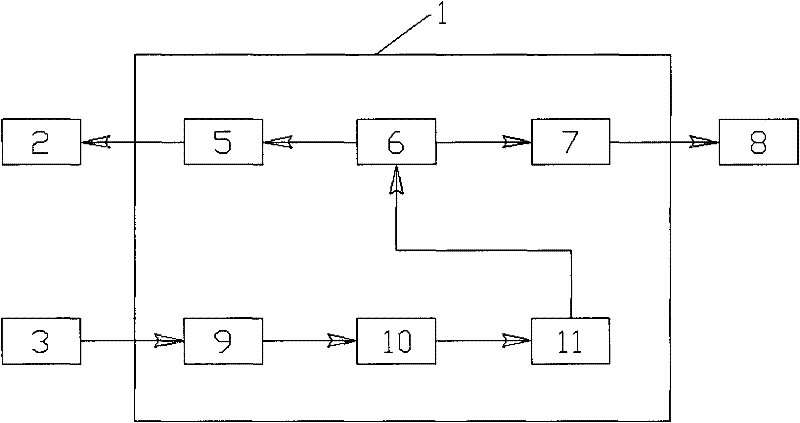

[0014] An ultrasonic transmitting probe 2 and an ultrasonic receiving probe 3 are installed on the outer wall of the upper end of the steel slag desulfurizer storage tank 4, the lower ends of the ultrasonic transmitting probe 2 and the ultrasonic receiving probe 3 are at the same height, and the ultrasonic transmitting probe is connected to the data processing through a lead wire The output end of the module 1 and the ultrasonic receiving probe 3 are connected to the input end of the data processing module 1 through lead wires. Ultrasonic receiving probe 3 signal is connected with receiving signal limiting protector 9, and receiving signal limiting protector 9 is connected with receiving signal amplifier 10, and receiving signal amplifier 10 is connected with receiving signal detector 11, and receiving signal detector 11 is connected with signal processor 6 connection, the signal output port of the signal processor 6 is connected with the ultrasonic transmitting probe 2 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com