Free-radical scavenger for resisting insulation aging of power cable and automatic healing method of free-radical scavenger

A technology for insulation aging and power cables, which is applied to organic insulators, plastic/resin/wax insulators, insulation/armoured cable repair equipment, etc., to achieve obvious anti-aging effects, inhibit aging aggravation, and shorten the implementation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Preparation of free radical scavenger solution

[0038] Fully mix 10 parts of 2,-methyl-4,6-bis(octylthiomethylene)phenol, 5 parts of dodecylbenzenesulfonic acid, 10 parts of siloxane and 50 parts of acetone, and disperse by ultrasonic Machine and sand mill disperser are combined to disperse to obtain free radical scavenger dispersion.

[0039] 2. Applying a free radical scavenger solution to the cable using a pressure injection system

[0040] Use an air compressor to compress the air so that the injection pressure is 0.1 MPa. After filtering through the filter bottle, add the dispersion of the above free radical scavenger into the free radical scavenger solution tank, and the free radical scavenger solution enters the exchange tank under pressure. Joint polyethylene cable core, stop injecting after 4h.

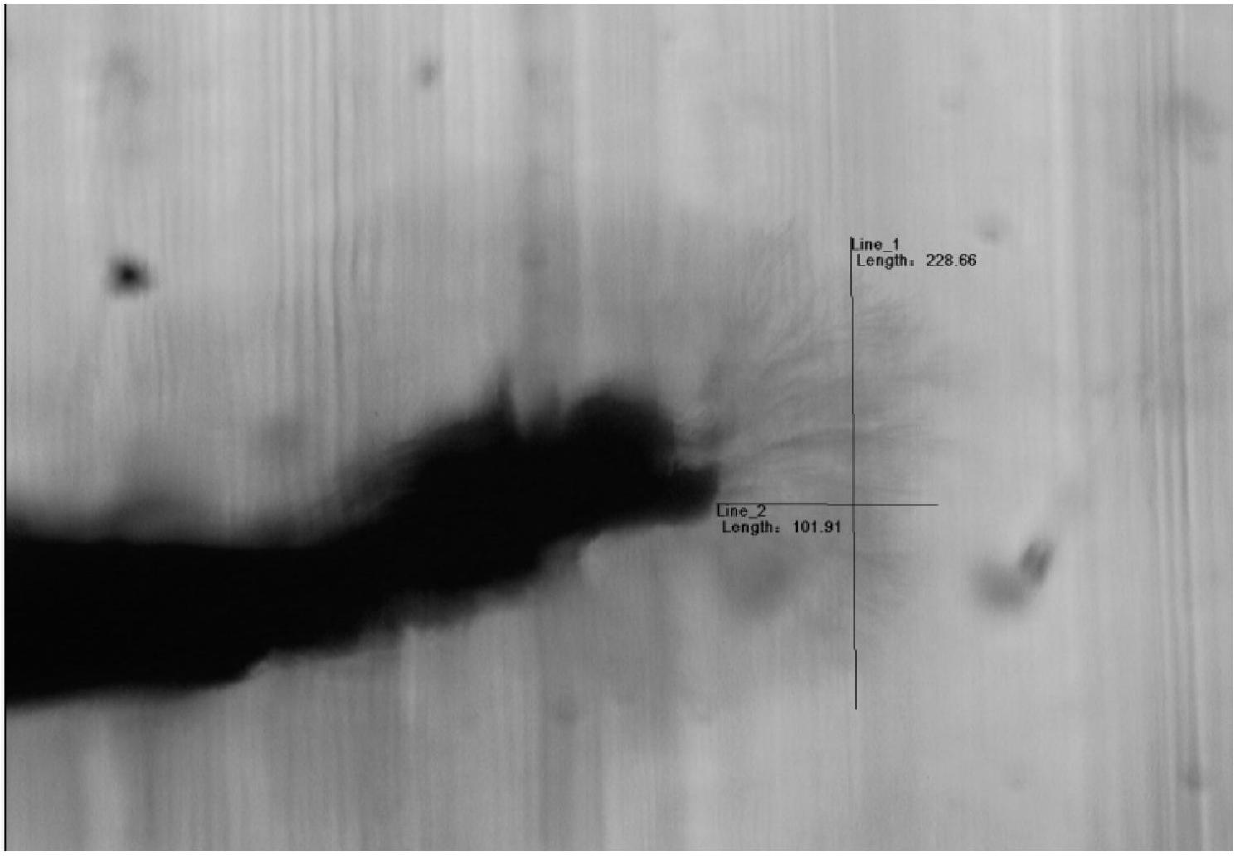

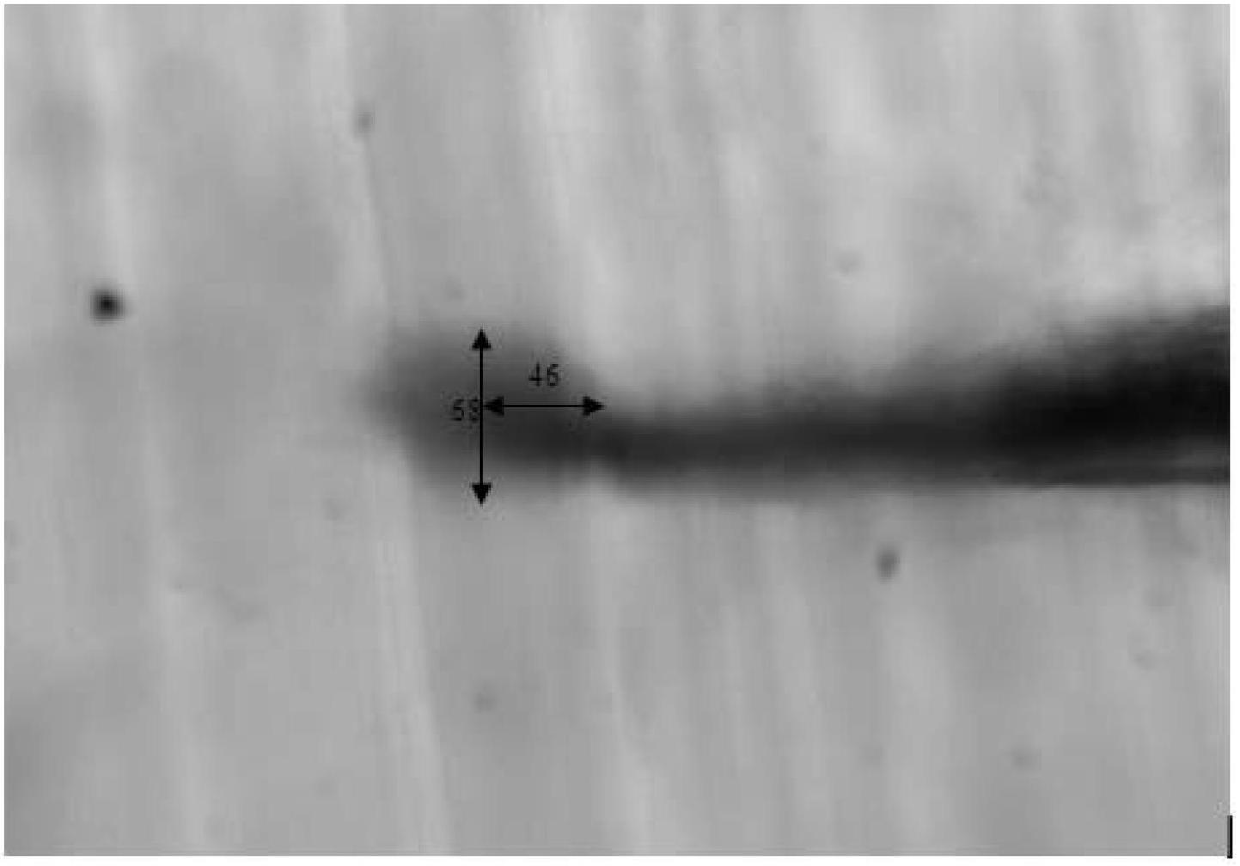

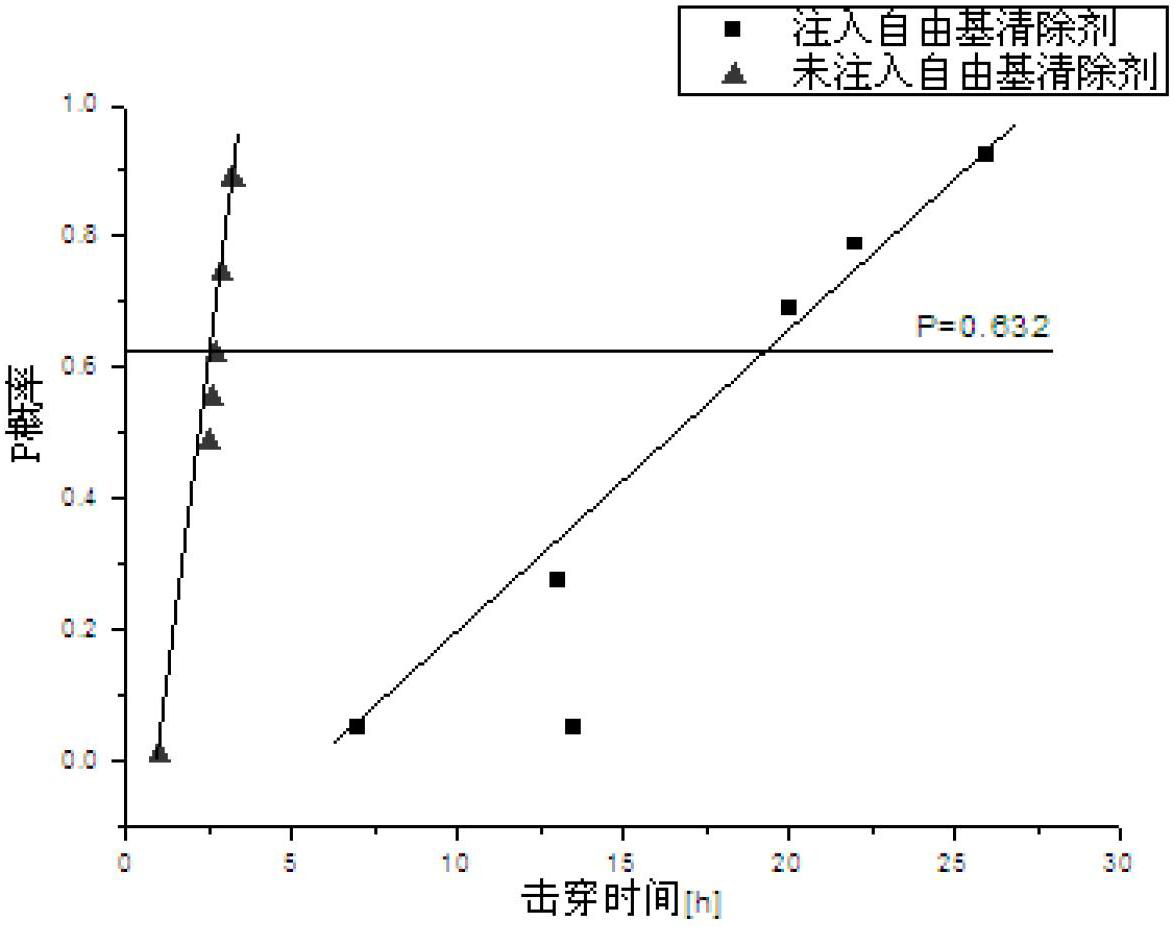

[0041] 3. Performance testing

[0042] Take 12 cable samples, 6 of which are injected with free radical scavenger solution, and the other 6 are not injected. Th...

Embodiment 2

[0044] 1. Preparation of free radical scavenger solution

[0045] Mix 15 parts of 2,-methyl-4,6-bis(octylthiomethylene)phenol, 8 parts of dodecylbenzenesulfonic acid, 15 parts of siloxane and 50 parts of chloroform, and disperse them by ultrasonic Machine and sand mill disperser are combined to disperse to obtain free radical scavenger dispersion.

[0046] 2. Applying a free radical scavenger solution to the cable using a pressure injection system

[0047] Use an air compressor to compress the air to make the injection pressure 0.2MPa. After filtering through the filter bottle, add the dispersion of the above free radical scavenger into the free radical scavenger solution tank, and the free radical scavenger solution enters the exchange tank under pressure. Joint polyethylene cable core, stop injecting after 3h.

[0048] 3. Performance testing

[0049] Take 10 cable samples, 5 of which are injected with free radical scavenger, and the other 5 are not injected. Apply 400Hz a...

Embodiment 3

[0051] 1. Preparation of free radical scavenger solution

[0052] Mix 20 parts of 2,-methyl-4,6-bis(octylthiomethylene)phenol, 10 parts of dodecylbenzenesulfonic acid, 20 parts of siloxane and 50 parts of ethanol, and disperse them by ultrasonic Machine and sand mill disperser are combined to disperse to obtain free radical scavenger dispersion.

[0053] 2. Applying a free radical scavenger solution to the cable using a pressure injection system

[0054] Use an air compressor to compress the air so that the injection pressure is 0.3MPa. After filtering through the filter bottle, add the dispersion of the above free radical scavenger into the free radical scavenger solution tank, and the free radical scavenger solution enters the exchange tank under pressure. Joint polyethylene cable core, stop injecting after 2h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com