Variable-frequency power electronic capacitor

A technology of power electronics and capacitors, which is applied in the field of organic dielectric fixed capacitors, can solve the problems of high impedance frequency characteristics and equivalent series resistance, increased active power consumption, and simple leakage of the process, so as to reduce the equivalent series resistance and improve Partial discharge voltage, effect of improving heat dissipation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

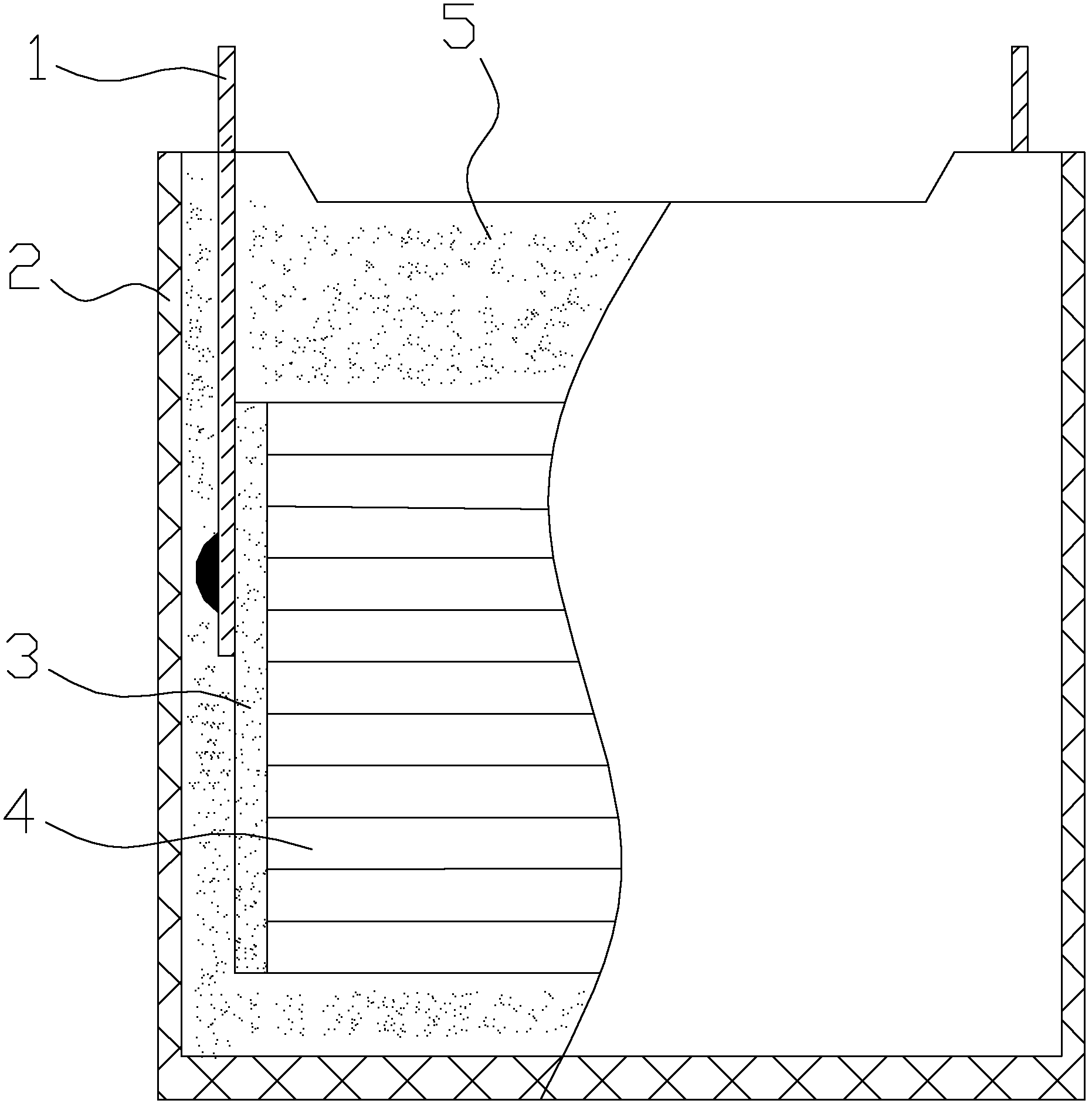

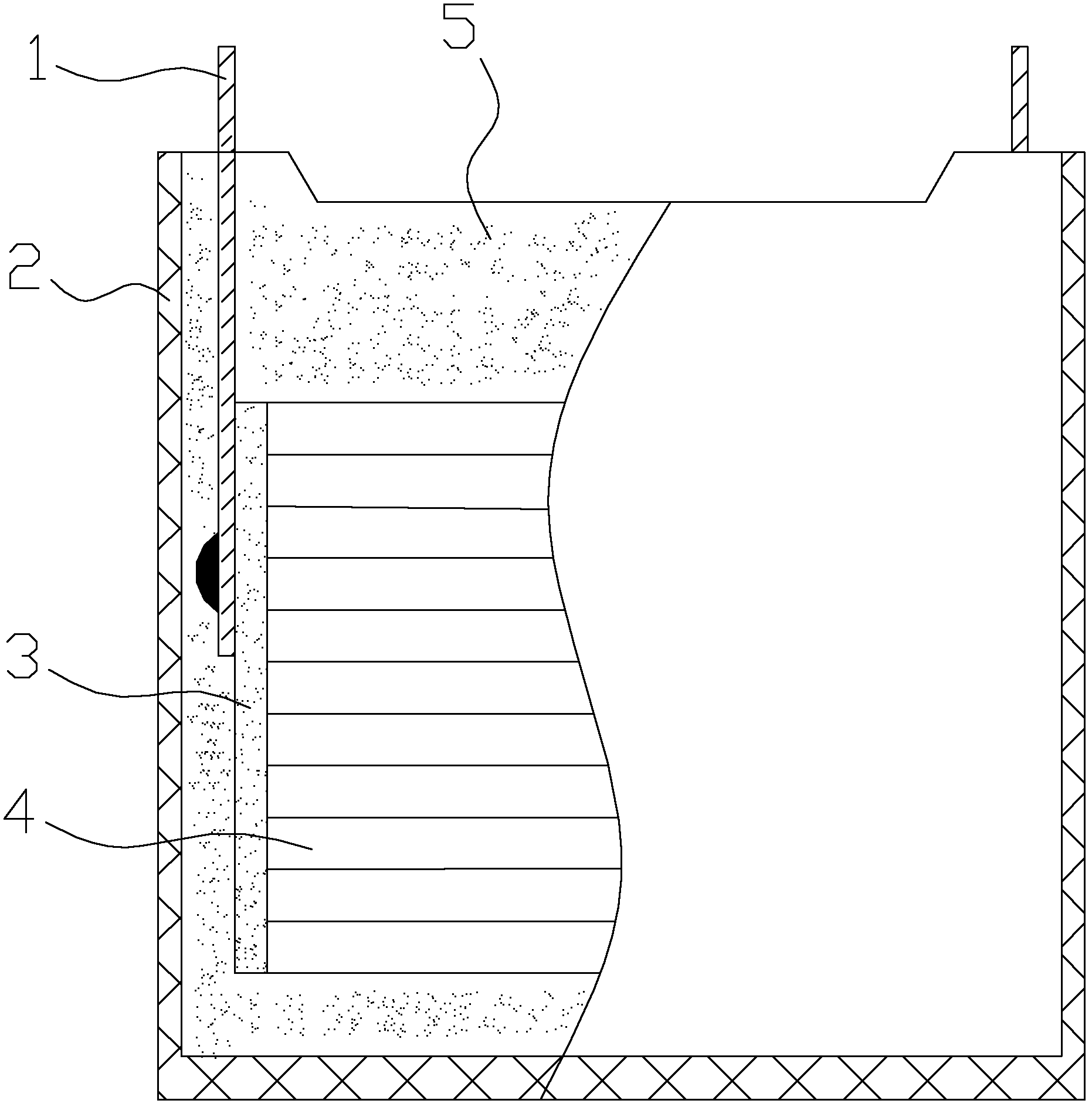

[0014] Such as figure 1 As shown, a variable frequency power electronic capacitor includes a shell 2, a core 4 is arranged inside the shell 2, the two ends of the core 4 are connected to the gold-sprayed layer 3, the outer side of the gold-sprayed layer 3 is connected to the soldering piece 1, and the shell 2 is filled with Filling material 5 is provided. The shell 2 is made of non-ferromagnetic material with low high-frequency eddy current heating. The non-ferromagnetic shell is made of aluminum or copper. The core 4 uses polypropylene film as the medium.

[0015] The basic principles and main features of the present invention and the advantages of the present invention have been shown and described above. Those skilled in the industry should ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com