Manganese dioxide asymmetric super capacitor and manufacturing method thereof

A supercapacitor, manganese dioxide technology, applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problems of high price, unsuitable for large-scale production, etc., and achieve the effects of low cost, improved energy density, and large potential window.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

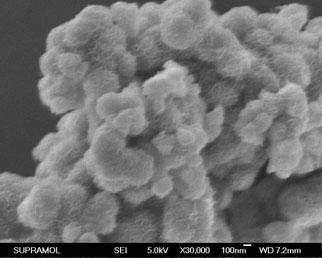

[0025] Weigh 1.0g of potassium permanganate and 0.5g of hydrated manganese sulfate, and then dissolve them in deionized water to obtain 15ml and 5ml of solutions; under strong stirring, add the manganese sulfate solution to the potassium permanganate solution drop by drop for 10 minutes. The addition is completed; transfer the mixed solution to a hydrothermal reaction kettle until the filling rate is 90%, hydrothermally react at 100°C for 3 hours to obtain a brown-black precipitate; wash with deionized water and dry at 80°C for 24 hours to obtain flower-shaped manganese dioxide .

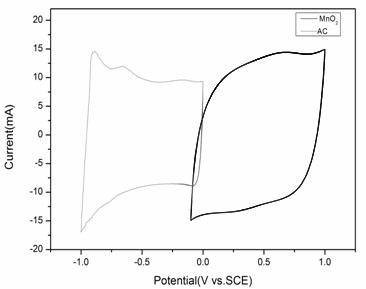

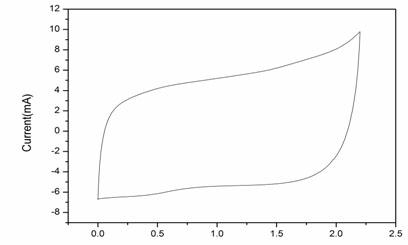

[0026] Using absolute ethanol as a dispersant, mix the prepared flower-shaped manganese dioxide with the conductive agent VGCF and the binder polytetrafluoroethylene in a mass ratio of 80:15:5, and evenly coat the foamed nickel, 80 °C drying to obtain a positive electrode.

[0027] Using absolute ethanol as a dispersant, mix activated carbon, conductive agent VGCF, and binder polytetrafluoroethylen...

Embodiment 2

[0030] Weigh 0.5g of activated carbon in 15ml of deionized water and sonicate for 1h, add 1.0g of potassium permanganate, and sonicate for 2h; dissolve 0.5g of manganese sulfate hydrate in 5ml of deionized water, and sonicate for 2h; The solution was added dropwise to the potassium permanganate / activated carbon solution, and the dropwise addition was completed in 10 minutes; the mixed solution was transferred to a hydrothermal reaction kettle until the filling rate was 90%, and after a hydrothermal reaction at 100°C for 3 hours, it was washed with deionized water and kept at 80°C Drying at low temperature for 24h, the nano-manganese dioxide / activated carbon composite material was obtained.

[0031]Using absolute ethanol as a dispersant, the prepared nano-manganese dioxide and activated carbon composite flower-shaped manganese dioxide were mixed with the conductive agent VGCF and the binder polytetrafluoroethylene in a mass ratio of 85:10:5. Evenly coated on foamed nickel, drie...

Embodiment 3

[0035] Weigh 1.0g of potassium permanganate and 0.5g of hydrated manganese sulfate, and then dissolve them in deionized water to obtain 15ml and 5ml of solutions; under strong stirring, add the manganese sulfate solution to the potassium permanganate solution drop by drop for 10 minutes. The addition is completed; transfer the mixed solution to a hydrothermal reaction kettle until the filling rate is 90%, hydrothermally react at 100°C for 3 hours to obtain a brown-black precipitate; wash with deionized water and dry at 80°C for 24 hours to obtain flower-shaped manganese dioxide .

[0036] Using absolute ethanol as a dispersant, mix the prepared flower-shaped manganese dioxide with the conductive agent VGCF and the binder polytetrafluoroethylene in a mass ratio of 90:5:5, and evenly coat the foamed nickel, 80 °C drying to obtain a positive electrode.

[0037] Using absolute ethanol as a dispersant, mix activated carbon, conductive agent VGCF, and binder polytetrafluoroethylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com