Method for manufacturing flat-plate fluorescent lamp

A manufacturing method and technology for fluorescent lamps, which are applied in the manufacture of discharge tubes/lamps, cold cathodes, electrode systems, etc., can solve the problems of cracked plates of fluorescent lamps, low air extraction efficiency, and small size of air injection ports, and can solve fatal problems. Defects, improve the pumping efficiency, improve the effect of vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0034] A method for manufacturing a flat fluorescent lamp, comprising the steps of:

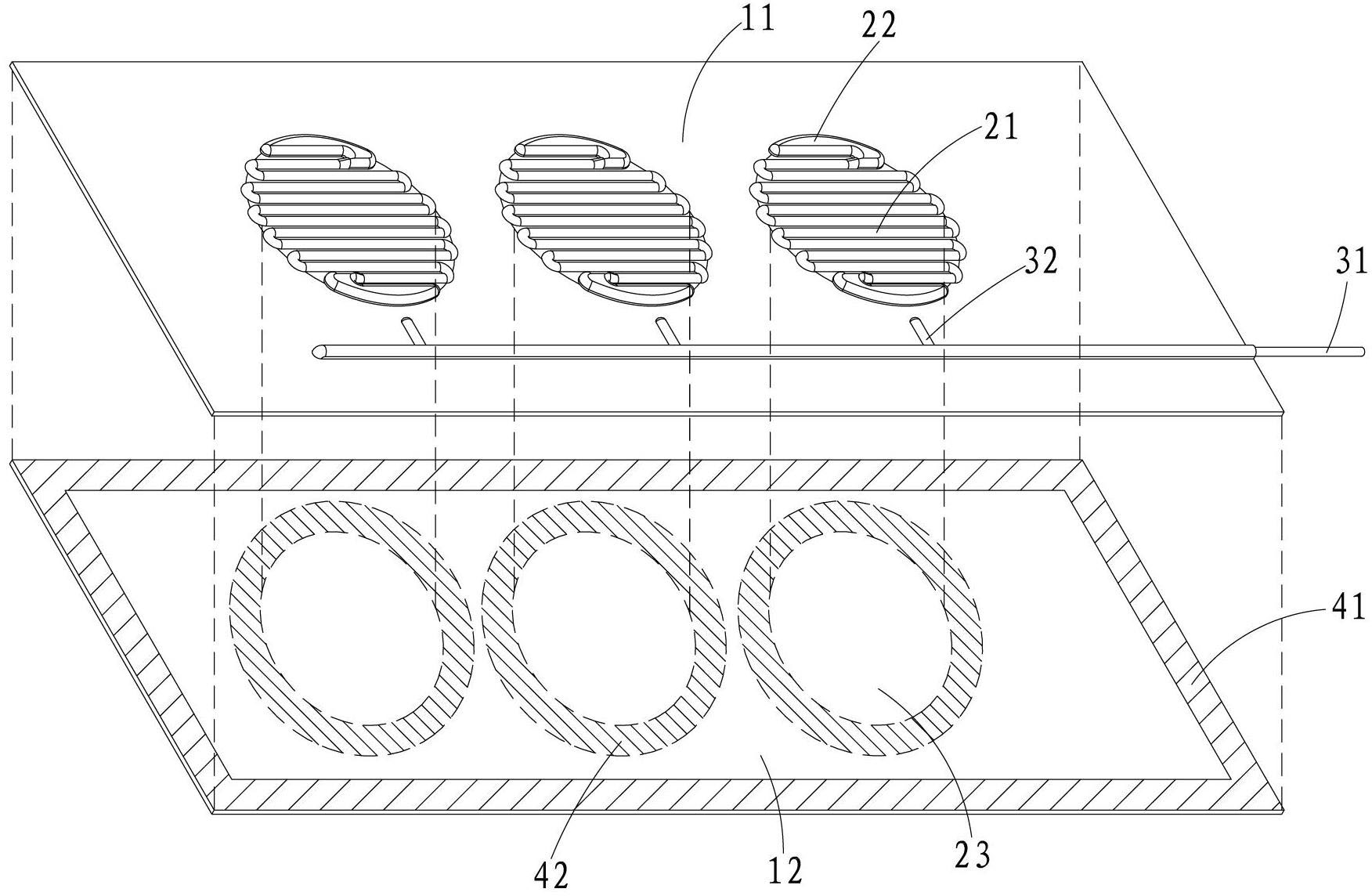

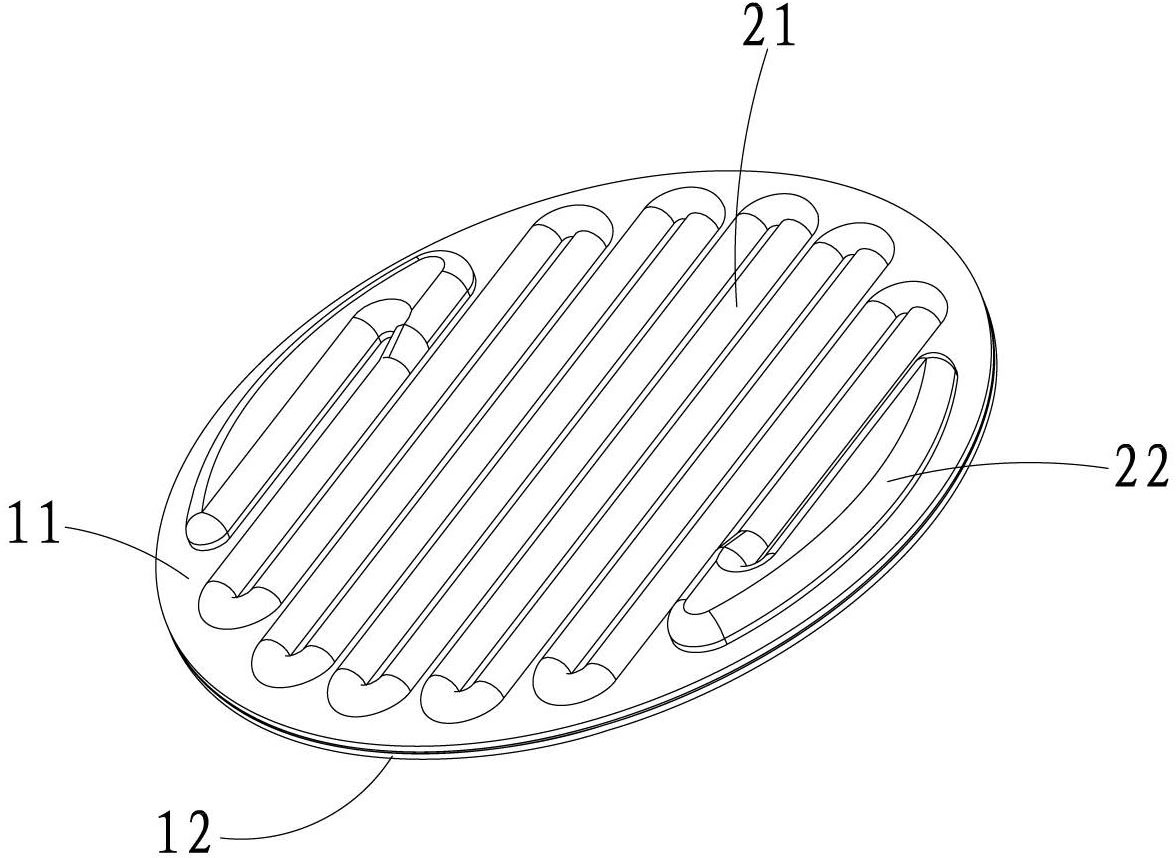

[0035] Step 1: If Figure 1A and Figure 1BAs shown, two glass plates are provided, a first glass plate 11 and an opposite second glass plate 12; wherein the first glass plate 11 is formed with discharge channels 21 and external electrodes 22 of three fluorescent lamps 20; on the first glass plate 11 An exhaust pipe 31 is provided at the edge of the first glass plate 11 , and an exhaust passage 32 is provided in the middle of the first glass plate 11 , and the exhaust passage 32 communicates with the exhaust pipe 31 .

[0036] Step 2: a first sealant 41 is provided on the periphery of the first glass plate 11 or the second glass plate 12, and a second sealant 42 is provided in the peripheral area 23 of the fluorescent lamp 20, wherein the melting point of the first sealant 41 is low at the melting point of the second sealant 42 .

[0037] Step 3: Attach the two glass plates 11, 12 together,...

no. 2 example

[0043] A method for manufacturing a flat fluorescent lamp, comprising the steps of:

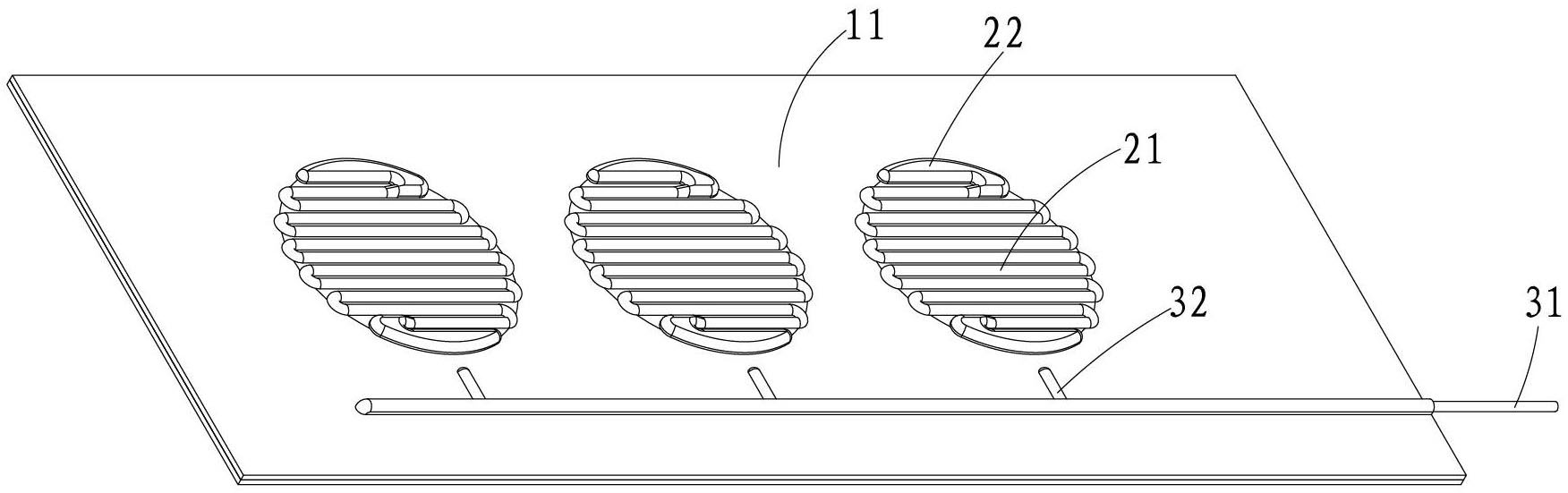

[0044] Step 1: If Figure 2A As shown, two glass plates are provided, a first glass plate 11 and an opposite second glass plate 12; wherein the first glass plate 11 is formed with discharge channels 21 and external electrodes 22 of three fluorescent lamps 20, and the corresponding positions Discharge channels 21 and external electrodes 22 of three fluorescent lamps 20 are also formed on the second glass plate 12; an exhaust pipe 31 is arranged at the edge of the first glass plate 11, and an exhaust pipe 31 is also arranged in the middle of the first glass plate 11. A channel 32 , the exhaust channel 32 communicates with the exhaust pipe 31 .

[0045] Step 2: a first sealant 41 is provided on the periphery of the first glass plate 11 or the second glass plate 12, and a second sealant 42 is provided in the peripheral area 23 of the fluorescent lamp 20, wherein the melting point of the first se...

no. 3 example

[0052] The remaining steps of this embodiment are the same as those of the first embodiment, except that in step 1, spacers are placed between the two glass plates to form discharge channels, electrodes, and exhaust channels.

[0053] In the present invention, since the sealing around the discharge channel of the fluorescent lamp is completed once after the fluorescent lamp forms a vacuum environment, the two glass plates of the fluorescent lamp are squeezed by the huge pressure inside and outside the glass plate before sealing, eliminating the gap caused by the process or material, so that the sealing After the agent is sealed and sealed, there is no deformation stress between the glass plates of the fluorescent lamp, which solves the fatal defect of cracking the plates during the lighting process of the flat fluorescent lamp. At the same time, the gap between the discharge tubes is eliminated, the discharge resistance is increased, and the problem of the short circuit of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com