Servo motor with built-in coupling

A technology of servo motor and coupling, applied in the field of servo motor, can solve the problems of large space between servo motor and coupling, affecting the driving accuracy of the motor, inconvenient installation and maintenance, etc., so as to save installation space, compact structure and maintenance cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] Such as Figure 2 to Figure 5 Shown is a preferred embodiment of the present invention.

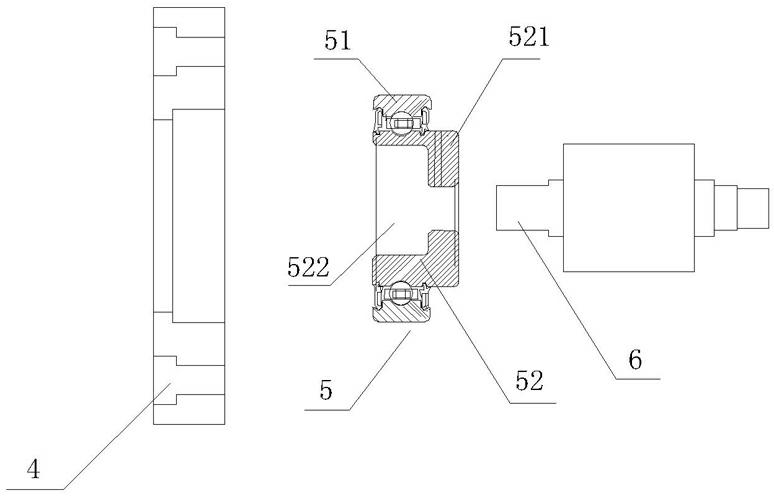

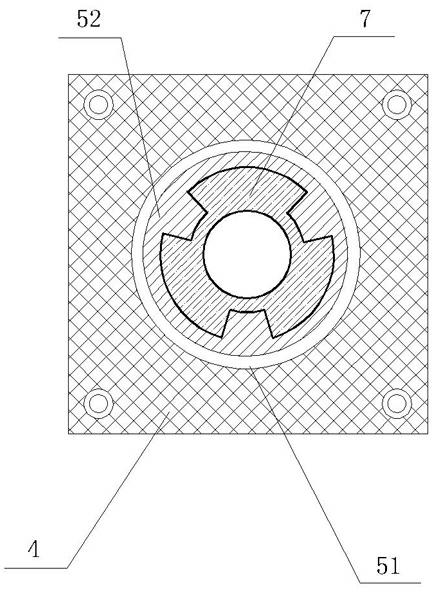

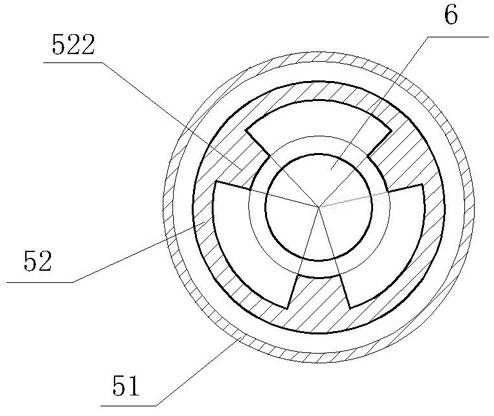

[0030] Such as figure 2 , image 3 As shown, a servo motor with a built-in coupling includes a motor output shaft 6, a coupling bearing 5 and a motor end cover 4. The motor output shaft 6 is positioned through the coupling bearing 5, and the coupling bearing 5 is fixed on the motor on the end cap 4. Of course, the above-mentioned servo motor also includes other components such as a rotor, and since these components belong to the prior art in this field, details will not be described here.

[0031] The coupling bearing 5 includes a bearing outer ring 51 and a bearing inner ring 52 . Of course, as a bearing, the coupling bearing also includes steel balls, cages, etc., and since these components belong to the prior art in this field, they ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com