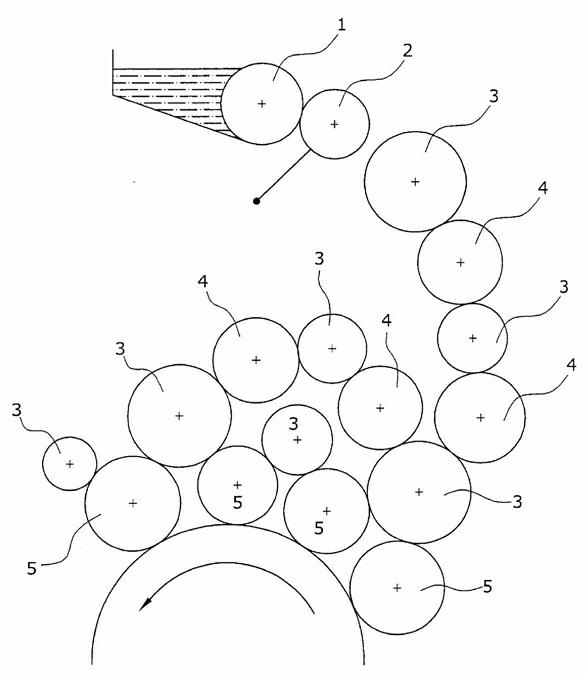

Oscillator rollers

A technology of stringing ink rollers and roller cores, which is applied in the field of manufacturing rigid rollers, can solve the problems of preventing effective heat dissipation of cloth ink rollers, and achieve the effects of good ink acceptance, effective heat dissipation, and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A solution of polyamic acid was applied to the steel core by thin film spin coating. The material was heated under rotation so that most of the solvent evaporated. This keeps the coating composition stable after the spin is over. Subsequently, the rolls are annealed at a maximum of 250°C. Printing experiments with this roll provided very good results.

Embodiment 2

[0051]In the method of Example 1, a steel core having a roughness Rz of 15 μm was used. After coating according to Example 1 at a thickness of 80 μm, an Rz of about 2.2 μm remained on the surface. After coating at a thickness of 30 μm, Rz is about 5 μm, ie the roughness of the coating can be adjusted by choosing the coating thickness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com