Aluminum titanate-mullite cellular ceramic and its production

A technology of honeycomb ceramics and mullite, which is applied in the field of silicate materials and industrial ceramics, can solve problems such as increased thermal expansion coefficient, reduced service life, and impact on service life, and achieves stable water absorption, high service life, and high resistance thermal shock effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

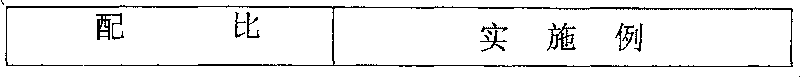

[0036] Embodiments of the present invention are shown in Table 1,

[0037] The preparation method of the present invention is,

[0038] Ingredients: Clay, alumina, titanium oxide, cristobalite, magnesium aluminum spinel and other raw materials are composed according to the following mass ratio:

[0039] Clay (alumina ≥ 30%) 45-65%

[0040] Aluminum oxide 25-39%

[0041] Titanium dioxide (titanium oxide ≥ 98%) 8 ~ 18%

[0042] Magnesium aluminum spinel 1~5%

[0043] Cristobalite 1~3%

[0044] The above-mentioned raw materials are molded according to the following steps:

[0045] Batching→ball milling and mixing→filtering mud→vacuum kneading and filtering mud→drying→mixing→aging→extruding→drying→firing

[0046] The aging is placed for 24-48 hours;

[0047] (The firing temperature is 1450~1600℃)

[0048] The aluminum titanate-mullite honeycomb ceramics obtained through the above steps.

[0049] Table 1

[0050]

[0051]

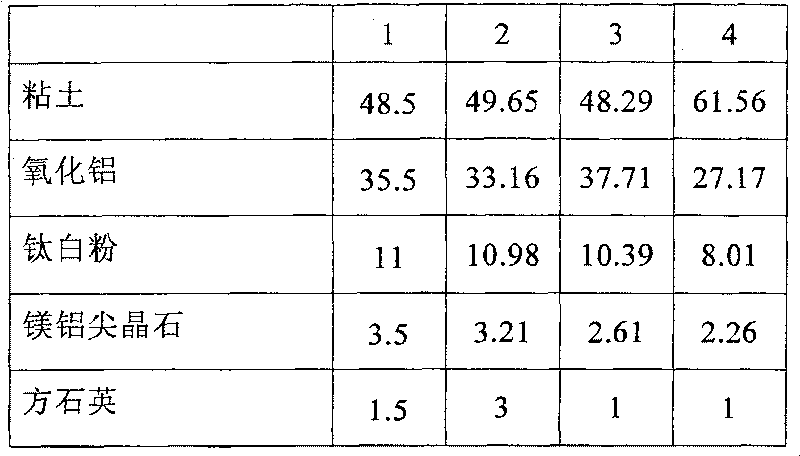

[0052] The physical properties of aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com