Oil-containing poly-dicyclopentadiene composite material and preparation method thereof

A technology of polydicyclopentadiene and dicyclopentadiene is applied to oil-containing polydicyclopentadiene composite materials. In the field of preparation of the composite materials, the problems of poor wear resistance and limited popularization and application can be solved, and the application range is wide. , The effect of improving wear resistance, high retention modulus and impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

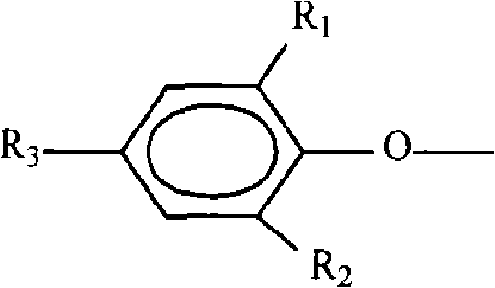

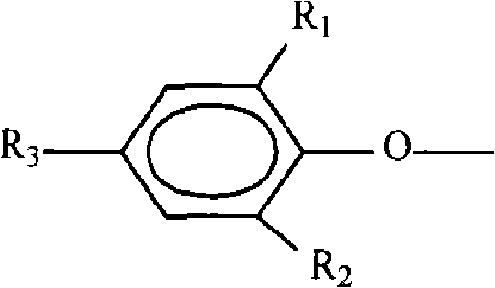

Method used

Image

Examples

Embodiment 1

[0022] The polydicyclopentadiene composite material of this embodiment is formed by the catalytic blending polymerization of the following raw materials in parts by weight: 95 parts of dicyclopentadiene, 5 parts of paraffin oil (Chengdu Gracia Chemical Technology Co., Ltd., CP), and the rest are Residual catalyst and unavoidable impurities.

[0023] The preparation method of the polydicyclopentadiene composite material of the present embodiment is as follows:

[0024] 1) At 50°C, add 5 parts of paraffin oil to 95 parts of dicyclopentadiene with a purity greater than 98%, stir evenly to make a dicyclopentadiene-paraffin oil dispersion, and to the obtained dicyclopentadiene The diene dispersion is degassed and then protected with an inert gas for use;

[0025] 2) Under nitrogen protection, add 20 kg of dicyclopentadiene-paraffin oil dispersion (40 kg in total, containing 2 kg of paraffin oil) to the A material tank and B material tank of the reaction injection molding machine r...

Embodiment 2

[0028] The polydicyclopentadiene composite material in this example is obtained by catalytic blending and polymerization of the following raw materials in parts by weight: 85 parts of dicyclopentadiene, 15 parts of silicone oil, and the rest are residual catalysts and unavoidable impurities.

[0029] The preparation method of the polydicyclopentadiene composite material of the present embodiment is as follows:

[0030] 1) At 60°C, add 15 parts of silicone oil to 85 parts of dicyclopentadiene with a purity greater than 98%, and stir evenly to make a dicyclopentadiene-silicone oil dispersion, and to the obtained dicyclopentadiene The dispersion is degassed and then protected with an inert gas for use;

[0031] 2) Add 20 kg of dicyclopentadiene-silicone oil dispersion (total 40 kg, containing 6 kg of silicone oil) to the A material tank and B material tank of the resin transfer molding machine respectively under nitrogen protection, the whole system is sealed and Protect with in...

Embodiment 3

[0034] The polydicyclopentadiene composite material of this embodiment is formed by the catalytic blending polymerization of the following raw materials in parts by weight: 70 parts of dicyclopentadiene, 30 parts of heavy liquid paraffin (Aladdin Reagent Company), and the rest are residual catalysts and unavoidable impurities.

[0035] The preparation method of the polydicyclopentadiene composite material of the present embodiment is as follows:

[0036] 1) At 40°C, add 30 parts of heavy liquid paraffin to 70 parts of dicyclopentadiene with a purity greater than 98%, stir evenly to make a dicyclopentadiene-heavy liquid paraffin dispersion, and The obtained dicyclopentadiene dispersion is degassed and then protected with an inert gas for use;

[0037] 2) Add 20 kilograms of dicyclopentadiene-heavy liquid paraffin dispersion (40 kilograms in total, containing 12 kilograms of heavy liquid paraffin) to the A material tank and B material tank of the reaction injection molding mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com